Self-catalyzed repairing hydrogel as well as preparation method and application thereof

A technology for water repair and autocatalysis, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, and pharmaceutical sciences. It can solve problems such as catalyst dependence, avoid side effects, ensure biocompatibility, and get rid of dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

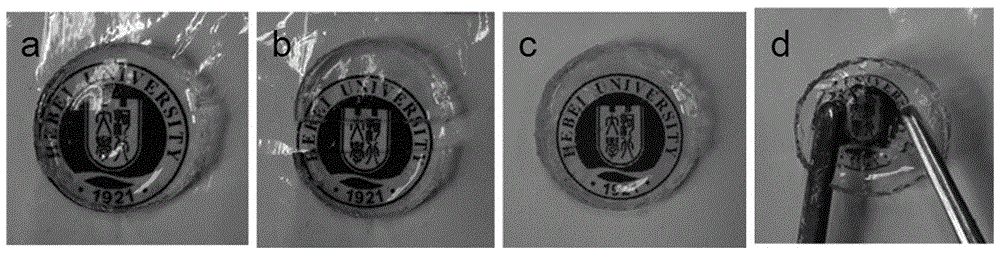

Examples

preparation example Construction

[0043] The embodiment of the present invention also discloses a preparation method of self-catalyzed repairing hydrogel, comprising the following steps:

[0044] a, copolymerization, 100 parts by weight of isopropylacrylamide and 5 to 400 parts (preferably 5 to 100 parts) of acrylate compounds are dissolved in a solvent, and free radical copolymerization (preferably living free radical polymerization) ), the reaction temperature is 30-120°C (preferably 60-100°C), the reaction time is 2-24h, preferably (12-24h), after the polymerization is completed, a precipitant is added to the reaction solution, and the residual monomer is removed by precipitation. (N-isopropylacrylamide)-acrylate copolymer was obtained. Among them, the acrylate compound is methyl acrylate, methyl methacrylate, ethyl acrylate, ethyl methacrylate, butyl acrylate, butyl methacrylate, hydroxyethyl acrylate or hydroxyethyl methacrylate One or more, preferably acrylate; the solvent used is N,N-dimethylformamide,...

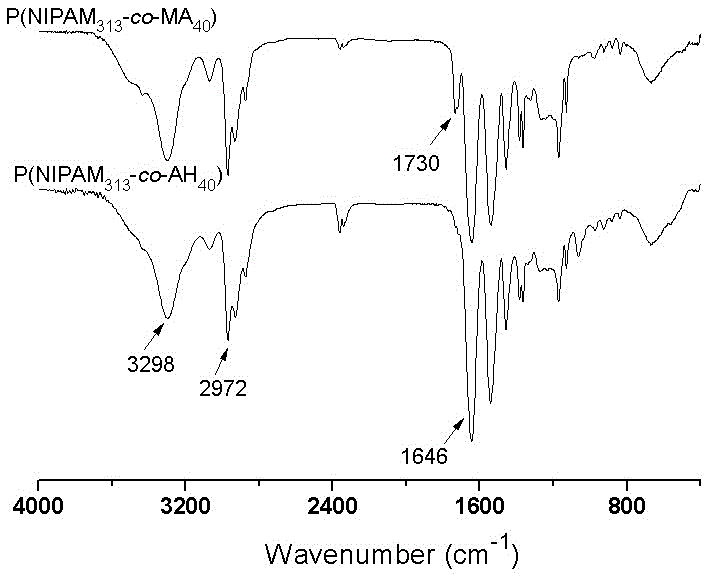

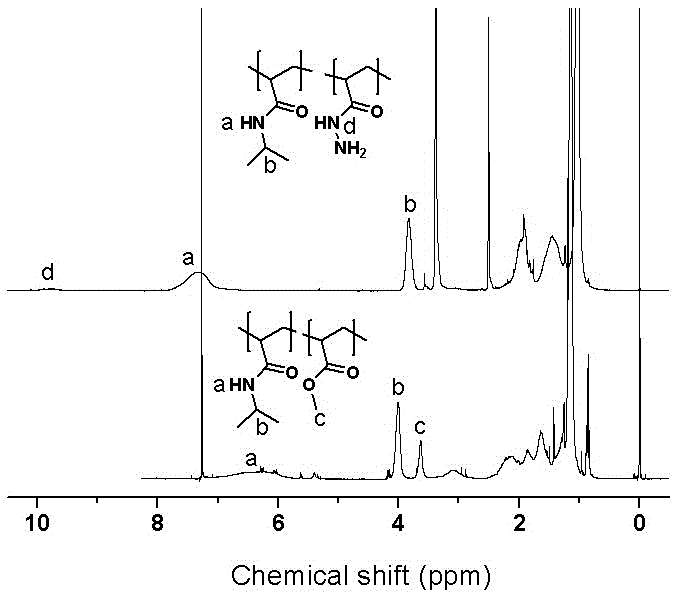

Embodiment 1

[0048] Copolymerization: Dissolve 10gNIPAM, 1g methyl acrylate, 5mg azobisisobutyronitrile (AIBN) and 50mgDDMAT chain transfer agent (DDMAT is dodecyl trithiocarbonate) in 15mL dioxane, and Add it into a 50mL reaction bottle, remove the oxygen in the system, and raise the temperature to 60°C under magnetic stirring to perform reversible addition-fragmentation chain transfer radical polymerization. The reaction time is 24h. After the reaction is completed, cool the reaction system and precipitate it with petroleum ether. Twice, remove the unreacted monomer, vacuum dry to get white powder, that is (N-isopropylacrylamide)-methyl acrylate copolymer, weigh and calculate monomer conversion rate and average molecular weight, and repeat in the copolymer The mass ratio of the unit NIPAM to the repeating unit methyl acrylate is about 10:1.

[0049] Hydrazinolysis: Dissolve 5g of the above copolymer in 10mL of methanol, then add 3.6mL of hydrazine hydrate, heat up to 70°C, hydrazinolysis...

Embodiment 2

[0056] Copolymerization: Dissolve 10g of NIPAM, 10g of butyl acrylate and 0.2g of azobisisobutyronitrile in 20mL of dioxane, and add it into a 100mL reaction bottle, and raise the temperature to 60°C under magnetic stirring and nitrogen protection for ordinary free reaction. base polymerization, the reaction time is 8h, after the reaction is over, the reaction system is cooled, precipitated twice with petroleum ether, the unreacted monomer is removed, and the white powder is obtained by vacuum drying, namely (N-isopropylacrylamide)-butyl acrylate For ester copolymers, the mass ratio of the two repeating units in the copolymer is about 1:1.

[0057] Hydrazinolysis: Dissolve 5g of the above copolymer in a mixed solvent of 5mL ethanol and 10mL hydrazine hydrate, raise the temperature to 80°C, and perform hydrazinolysis for 48 hours, then put the reaction mixture into a dialysis bag and dialyze with deionized water for 48 hours to remove excess hydration Hydrazine and ethanol, fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com