Porous hyperbranched polyester graphite oxide membrane, and preparation method and application thereof

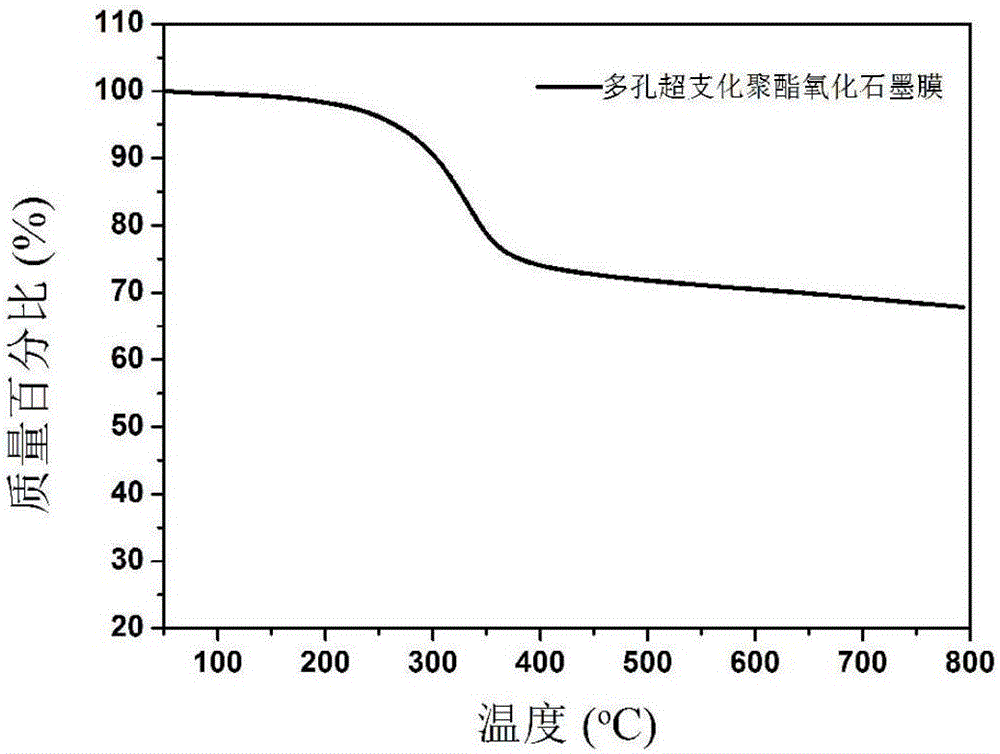

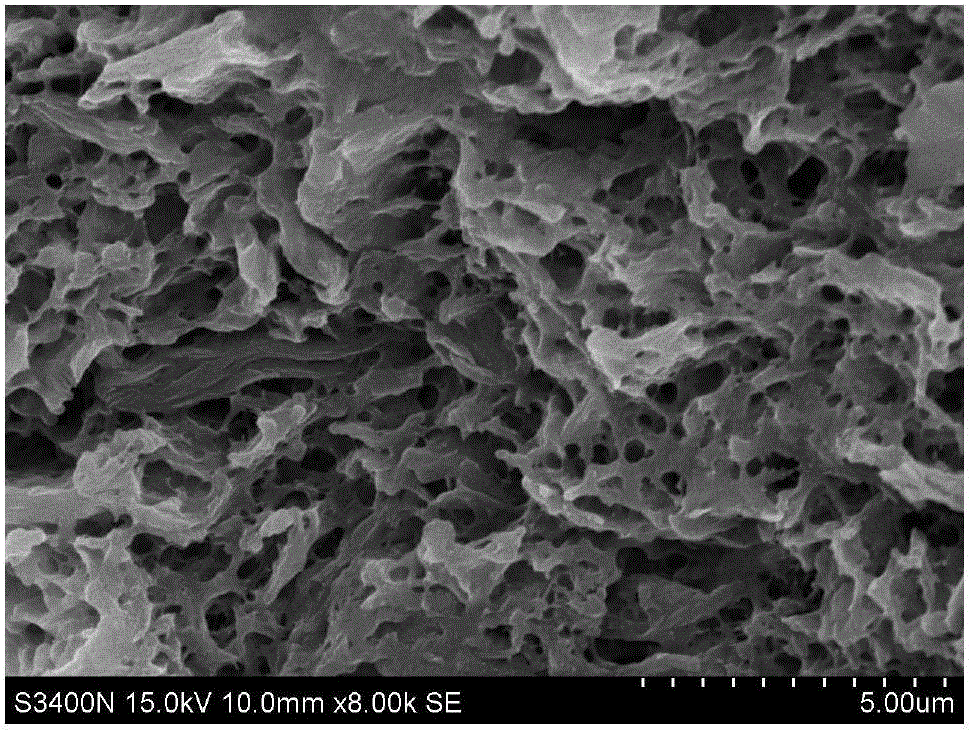

A technology of hyperbranched polyester and hyperbranched polyether, which is applied in the field of porous membrane materials, can solve the problems of melting, thermal shrinkage and melting of battery separators, and achieve high affinity, solve thermal shrinkage and melting, and superior heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation:

[0042] S1. Dissolve 1.17g of metal potassium in methanol to form a 30wt% potassium methoxide solution, weigh 1.34g of trimethylolpropane and the above 30wt% potassium methoxide solution, reflux and condense under nitrogen and heat to 90°C , and then 46.62g of glycidol was slowly added dropwise to the above-mentioned solution by titration to react for 12h, the solution after the reaction was dissolved in 40mL of methanol, and 2wt% hydrochloric acid solution was added dropwise to the above-mentioned solution. properties, and then the solution was purified by co-precipitation in 250 mL of acetone to obtain light yellow transparent hyperbranched polyether polyol.

[0043] S2. Take 10 mL of styrene monomer that has been treated with basic alumina and add it to a three-necked flask filled with 100 mL of water and 0.01 g of sodium dodecylbenzenesulfonate, blow nitrogen gas, and pre-emulsify at 55 ° C for 30 min, then Weigh 0.1 g of potassium persulfate, diss...

Embodiment 2

[0051] Different from Example 1, the reaction time is 24h; the amount of sodium dodecylbenzenesulfonate in the emulsion polymerization reaction in the S2 is 0.02g, and the average particle diameter obtained is a polystyrene emulsion of 310nm; after determination, the above-mentioned preparation The porous hyperbranched polyester graphite oxide film has a thickness of 113 μm and a liquid absorption rate of 134%.

Embodiment 3

[0053] Different from Example 1, the reaction time is 24h; the amount of sodium dodecylbenzenesulfonate in the emulsion polymerization reaction in the S2 is 0.03g, and the polystyrene emulsion with an average particle diameter of 240nm is obtained; after determination, the above-mentioned preparation The porous hyperbranched polyester graphite oxide film has a thickness of 106 μm and a liquid absorption rate of 128%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com