Construction method of corynebacterium glutamicum engineering bacteria for high production of L-lysine

A technology of glutamic acid rods and construction methods, applied in the direction of microorganism-based methods, other methods of inserting foreign genetic materials, genetic engineering, etc., can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Construction of gene knockout fragments

[0058] 1) (i) extracting the genomic DNA of Corynebacterium glutamicum (Corynebacterium glutamicum) 23604, using the genomic DNA as a template, performing PCR amplification to obtain the homology arm NCg1;

[0059] Described PCR primer sequence is as follows:

[0060] F1:CG GGATCC CGTTTTTCATGCTTGCCGTCT;

[0061] R1: AAGGCCAGCAAAAGCTAAAGCCCAAGAATGCAAC;

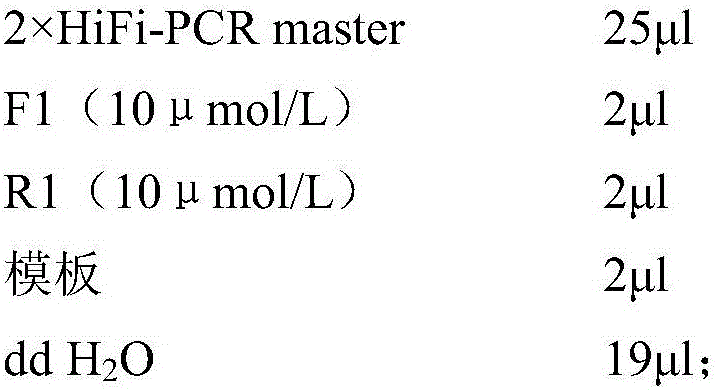

[0062] Described PCR amplification system is:

[0063]

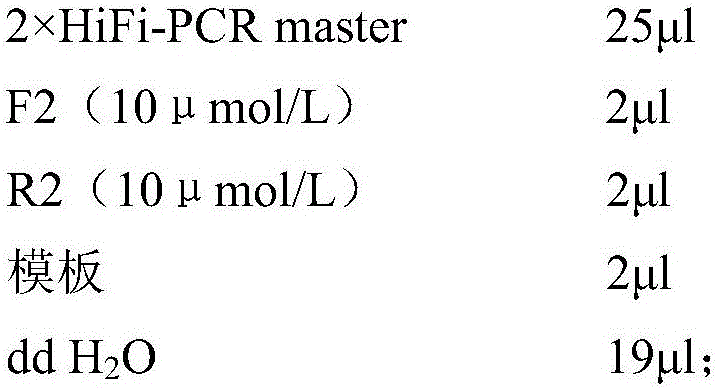

[0064]

[0065] The PCR amplification procedure is as follows:

[0066] Pre-denaturation at 95°C for 5 min; denaturation at 94°C for 30 sec, annealing at 55°C for 30 sec, extension at 72°C for 30 sec, 30 cycles; extension at 72°C for 10 min, storage at 4°C;

[0067] The PCR product was checked by agarose gel electrophoresis, the length was 528bp, and the SanPrep column DNA gel recovery kit (Shanghai Sangong) was used for gel recovery, and the recovered product was stored at -20°C for later use;

[006...

Embodiment 2

[0086] Embodiment 2: preparation bacillus licheniformis competent

[0087] (i) Pick a single colony of Corynebacterium glutamicum (Corynebacterium glutamicum) 23604, inoculate it in 10 mL of seed medium, cultivate overnight at 37°C and 220 r / min;

[0088] Seed medium, the components are as follows:

[0089] Peptone 10g, yeast powder 5g, sodium chloride 10g, sorbitol 91g.

[0090] (ii) Take 1mL of the above bacterial solution and transfer it to 100mL seed medium, and cultivate it to OD at 37°C and 220r / min 600 =0.9;

[0091] (iii) Transfer the bacterial solution to a 100mL centrifuge tube, and place it in an ice bath for 15-20 minutes to stop the growth of the bacterial cells;

[0092] (iv) Centrifuge at 4°C, 5000g, 5min after ice bath, and collect the bacteria;

[0093] (v) The thalline after centrifugation is washed 3 times with pre-cooled electroporation buffer (ETM);

[0094] Electroporation buffer, the composition per liter is as follows:

[0095] Sorbitol 91g, Manni...

Embodiment 3

[0098] Example 3: NCg1-Cm r Fragment electrotransformation of Corynebacterium glutamicum 23604

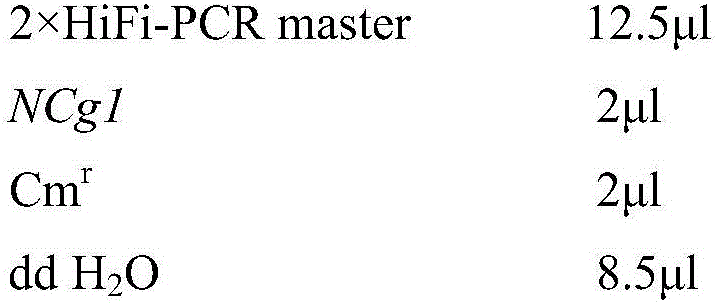

[0099] (i) NCg1-Cm r The fragment was digested with restriction endonuclease BamH I at 30°C for 3 h; the digestion system (40 μL) was as follows:

[0100]

[0101] (ii) Concentrate and purify the digested product

[0102] (1) Add 1 / 10 volume of 3M sodium acetate and 2.5 volumes of absolute ethanol, and place in a -20°C refrigerator for 20 minutes;

[0103] (2) Centrifuge at 12000r / min for 5min to obtain a precipitate;

[0104] (3) 300 μL of 75% ethanol by volume to resuspend the pellet;

[0105] (4) Centrifuge at 12000r / min for 5min, remove ethanol, and air-dry at 37°C for 30min,

[0106] (5) Add 15-18μL ddH 2 O Resuspend DNA and store at -20°C.

[0107] (iii) Electroconversion

[0108] Firstly, NCg1-Cm was measured by nucleic acid ultramicro spectrophotometer r Fragment concentration, after reaching 300 μg / mL concentration, 2100V electric shock for 5ms, and electrotran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com