Compound microbial inoculant as well as preparation method and application thereof

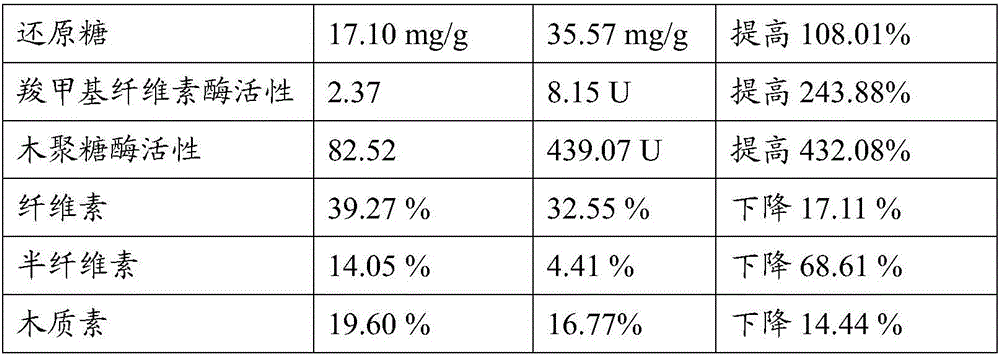

The technology of compound microbial inoculum and inoculum is applied in the field of microbial technology treatment of organic waste agricultural resources, which can solve the problems of low reduction of crude fiber content, long fermentation time, unsatisfactory effect, etc. Simple fermentation process and improved carboxymethyl cellulase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Culture medium preparation

[0044] PDA medium formula (g / L): potato dipping powder 3.0, glucose 20.0, agar 15.0, natural pH.

[0045] Cha's medium formula (g / L): 30.0 sucrose, 12.0 agar, NaNO 3 3.0, MgSO 4 ·7H 2 O 0.5, KCl 0.5, FeSO 4 ·7H 2 O 0.01, K 2 HPO 4 1.0, natural pH.

[0046] Prepared according to the recipe, boiled, put into a clean Erlenmeyer flask, sealed with a parafilm, tightened with a rubber band, sterilized under high pressure at 121°C for 20 minutes, took it out and put it on a super-clean workbench (turn on ultraviolet sterilization and ventilation), and cool to 40- At 60°C, pour it into a sterile plate (uniform, horizontal, without air bubbles), cool and condense into a solid state, and set aside.

Embodiment 2

[0047] Example 2 Culture of the strain

[0048] Phanerochaete chrysosporium (ACCC 30414) and Trichoderma konshii (CGMCC 3.2878) were activated twice on PDA medium, and then cultured on PDA plate medium at 28°C until a large number of spores were produced (about a week).

[0049] Aspergillus niger (ACCC 30557) and Aspergillus fig (NTG-23) were activated twice on Zapei's medium, and then cultured on Chapei's plate medium at 28°C until a large number of spores were produced (about a week).

Embodiment 3

[0050] Example 3 Preparation of spore suspension

[0051] 1. Elute the spores of the four kinds of bacteria from the plate with sterile physiological saline (0.9% NaCl solution), and obtain the spore liquid of each bacteria respectively (the operation process is aseptic operation).

[0052] 2. Place the obtained spore liquid in a 250mL Erlenmeyer flask (with glass beads) and shake it on a shaker at 150rmp for 4 hours at room temperature to break up and disperse the spores.

[0053] 3. The spore liquid after shaking is filtered with 8 layers of gauze (using a funnel and a glass rod) to obtain a spore suspension.

[0054] 4. Using the method of observing and counting under the microscope of a hemocytometer, adjust the spore suspension of various bacteria to 1×10 6 spores / mL, set aside.

[0055] The spore suspension can also be processed into a dry spore powder inoculum by vacuum freeze-drying technology, so as to be convenient for preservation or packaging for commercial use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com