Hydrophilic-oleophobic material, and preparation method and application thereof

An oleophobic and hydrophilic technology, used in separation methods, chemical instruments and methods, grease/oily substances/floating matter removal devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In some more specific embodiments, the preparation method includes the following steps:

[0036] Step 1: providing a porous material containing a hydrophilic group;

[0037] Step 2: cutting the porous material into the desired size, soaking it in a solvent and performing ultrasonic cleaning to remove stains and grease in the porous material, and then fully drying in a drying oven to remove moisture in the porous material;

[0038] Step 3: Dissolving the fluorocarbon surfactant containing amino groups, hydroxyl groups, carboxyl groups, fluorocarbon bonds, and alkyl chains in an organic solvent, and adding the porous material obtained in step 2 to the above solution under a certain reaction atmosphere, Mix evenly, react at a certain temperature and time, and bond the hydrophilic group contained in the hydrophilic porous material with the polar group of the fluorocarbon surfactant. After the reaction is completed, remove the excess solution and use an organic solvent, deio...

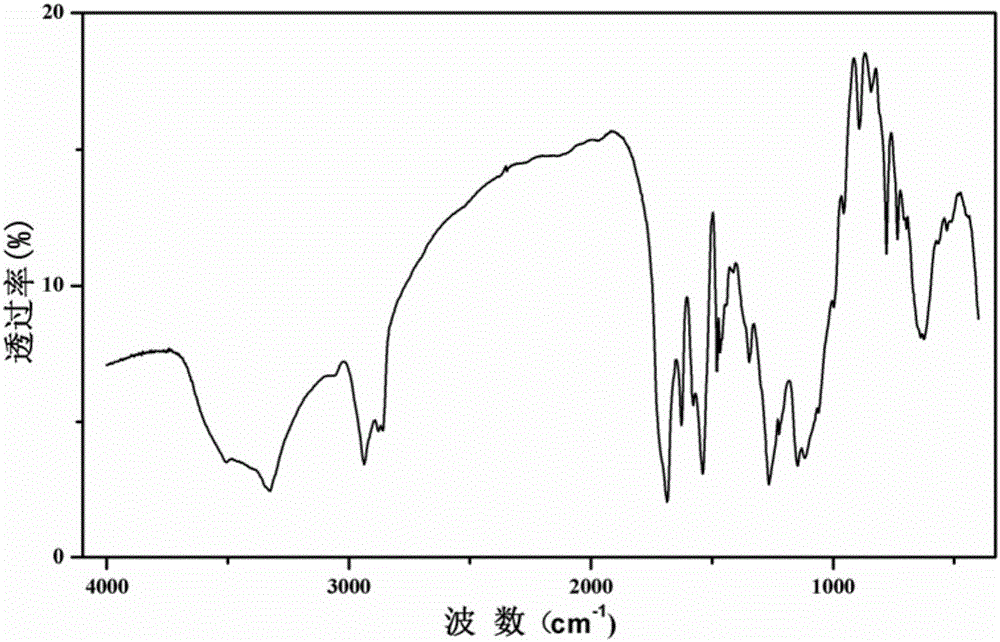

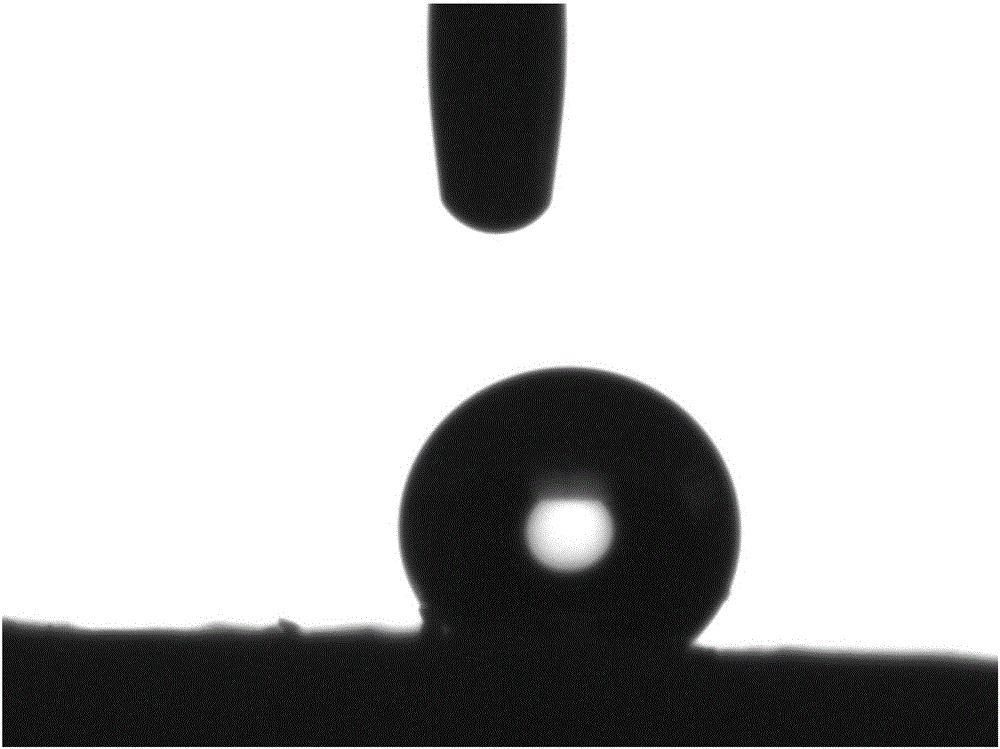

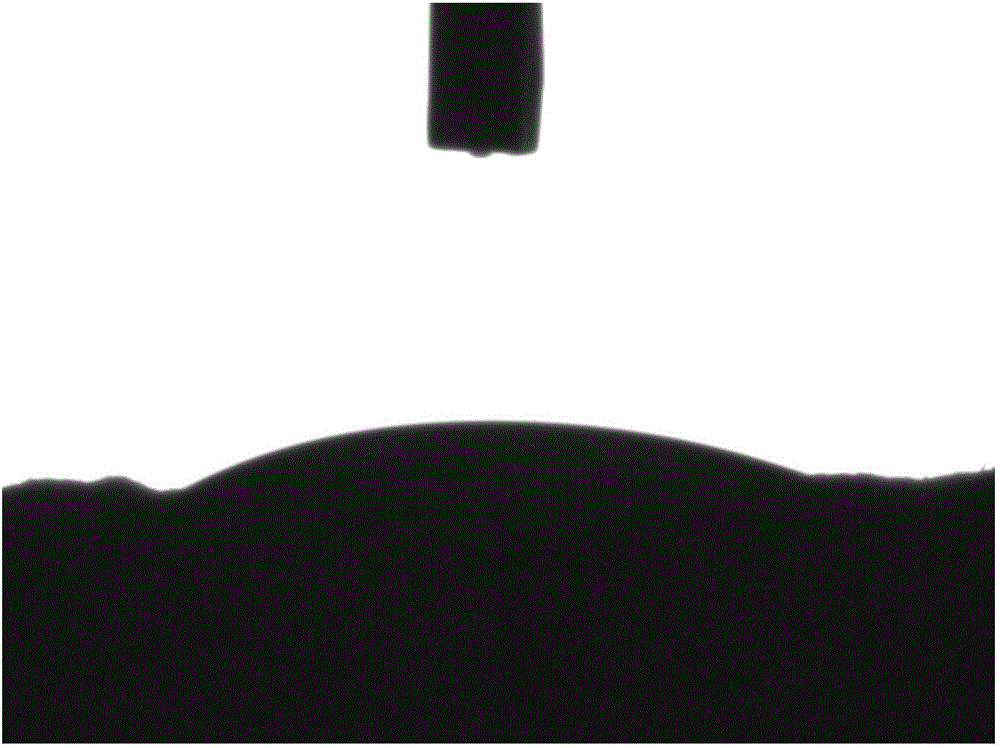

Embodiment 1

[0060] Example 1 The hydrophilic-oleophobic material in this example uses the same porous cellulose material as in Comparative Example 1 as the substrate, and after grafting C-F long chains containing hydrophilic amino groups and oleophobic properties on the substrate form. The C-F long chain is to react the cellulose porous material with a compound containing diisocyanate groups first, and then react with a fluorocarbon surfactant containing a hydroxyl group and a C-F long chain, so that the porous material and the fluorocarbon surfactant The hydroxyl groups of each group are chemically bonded with the -NCO functional group respectively, so that the C-F long chain is grafted on the surface of the porous material.

[0061] Specifically, the preparation process of the hydrophilic-oleophobic material comprises the following steps:

[0062] (1) Referring to Comparative Example 1, the cellulose porous material was cleaned and dried.

Embodiment 2

[0078] Example 2 The porous fabric material used in the preparation method of the hydrophilic-oleophobic fabric porous material in this example is basically the same as that in Comparative Example 2. This preparation method comprises the steps:

[0079] (1) Clean and dry the porous fabric material, specifically: cut the porous fabric material into the required size, soak it in a solution of deionized water and acetone, and perform ultrasonic cleaning for 30 minutes to remove the impurities in the porous material. Stains and grease, and then dried in a drying oven at 80°C;

[0080] (2) Calculate the hydroxyl molar mass of the fabric porous material, measure hexamethylene diisocyanate, 0.02g of dibutyltin dilaurate and 100ml of anhydrous toluene with twice the hydroxyl molar mass, and mix them evenly. After the treatment in step (1), Add the fabric porous material into it, seal it, pass nitrogen gas, react at 40°C for 6 hours, remove excess solution, and wash with anhydrous tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com