Graphene loaded zirconium oxide composite material, preparing method thereof, and application thereof as desulfurizer adsorbent

A composite material, zirconia technology, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve the problem of limited specific surface area and effective adsorption area of composite materials, easy agglomeration of nano-ions, and poor distribution uniformity. and other problems, to achieve the effect of easy regeneration and recycling, large adsorption capacity, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

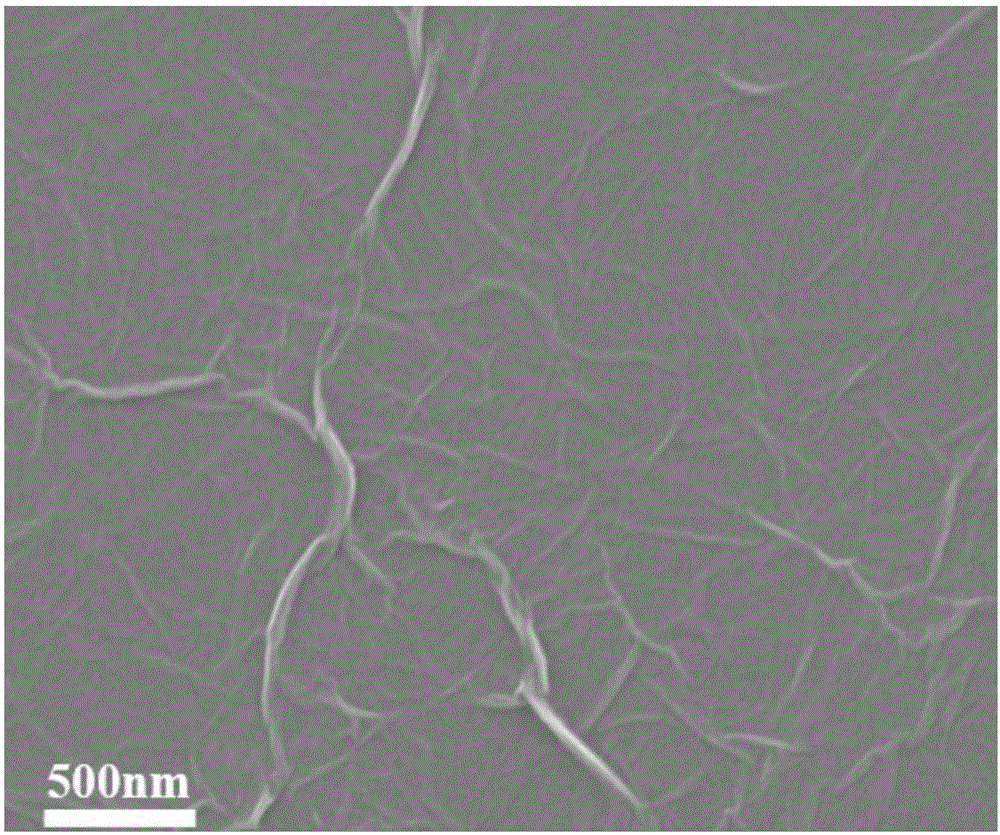

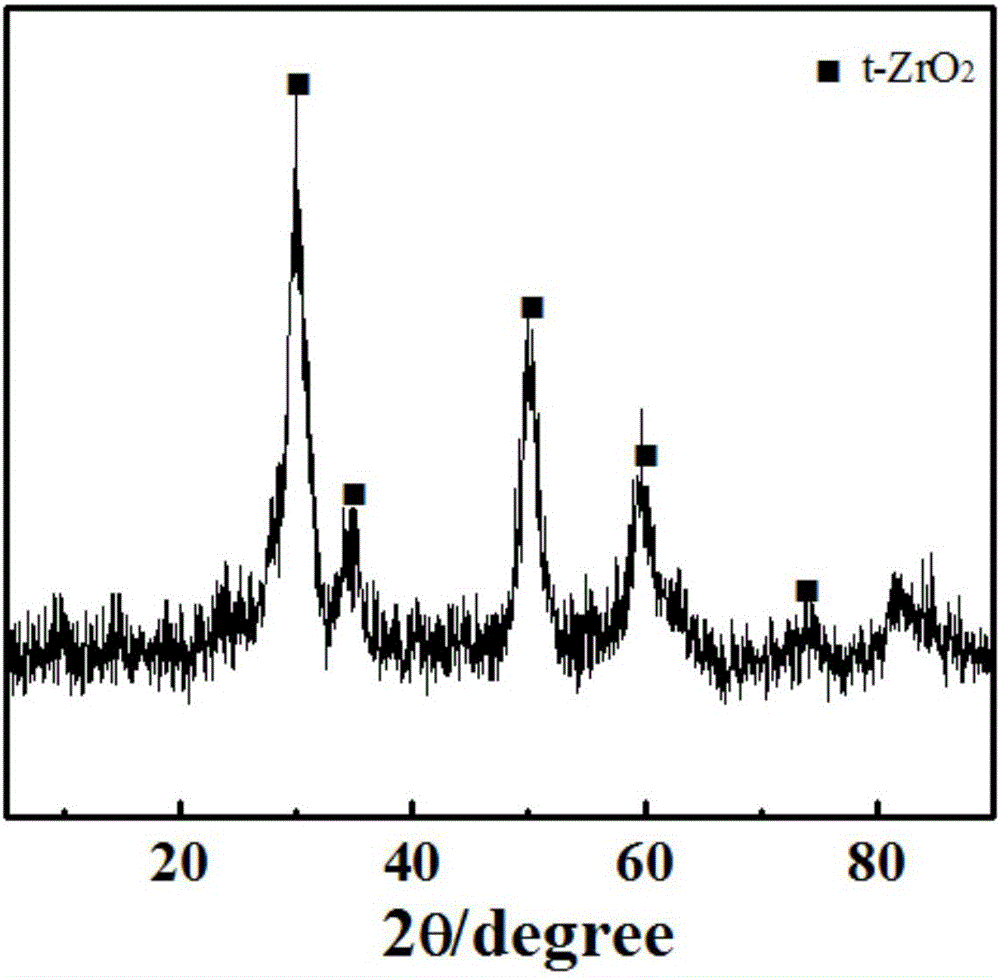

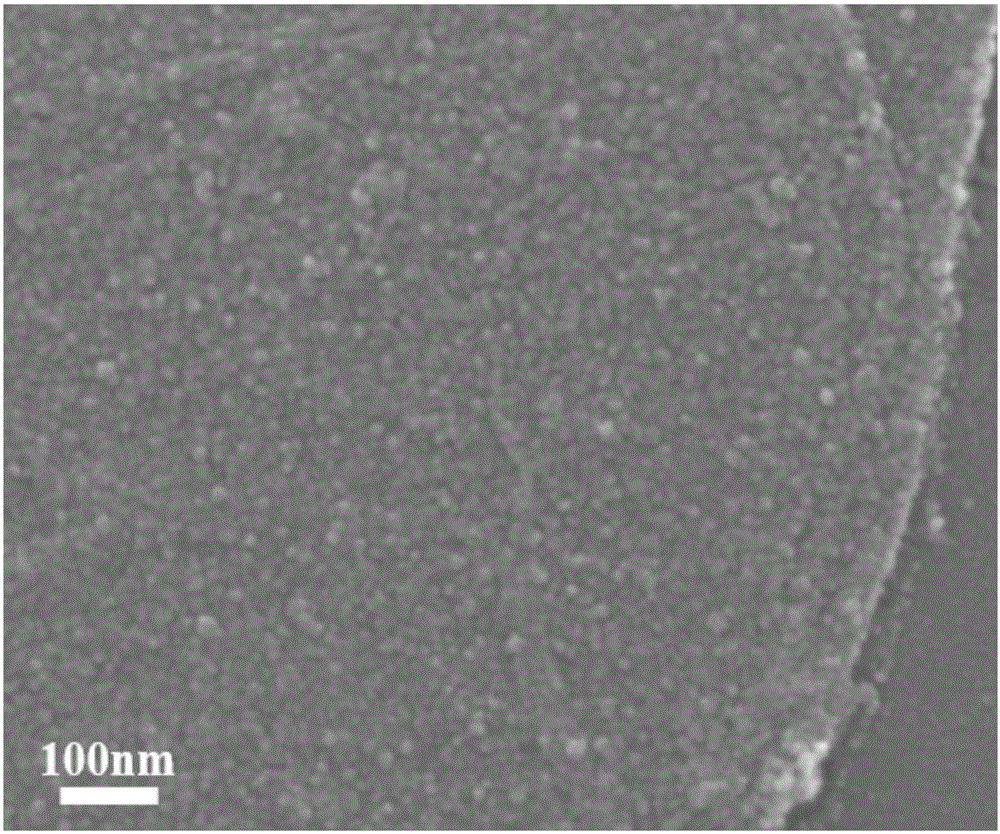

[0049] The graphene-supported zirconia composite material of the present embodiment is prepared by the following method:

[0050] 1) Preparation of graphene oxide dispersion:

[0051] a) Add 138ml of concentrated sulfuric acid (mass concentration: 98%) in a 1000ml beaker, place in an ice-water bath, and add 3.0g of NaNO successively under stirring conditions 3 and 3.0 g of graphite powder, continue to stir vigorously for 15 min; slowly add 18.0 g of potassium permanganate, stir for 2 h to react, and obtain mixture A;

[0052] b) Place the beaker containing the obtained mixture A in a constant temperature water bath at 35°C, and after stirring for 1 hour, transfer the beaker to an ice-water bath, add 240ml of deionized water dropwise, and control the temperature of the system below 60°C to obtain mixture B;

[0053] c) Place the beaker containing the obtained mixture B in a 95°C water bath, and stir for 30 minutes; transfer the beaker to room temperature, and add 600ml of deio...

Embodiment 2

[0061] The graphene-supported zirconia composite material of the present embodiment is prepared by the following method:

[0062] 1) Preparation of graphene oxide dispersion:

[0063] a) Under the condition of 0~3℃, 1.0g of NaNO 3 Add 2.0g of graphite powder into 92ml of concentrated sulfuric acid, slowly add 12.0g of potassium permanganate, stir for 2h to react, and obtain mixture A;

[0064] b) Place the beaker containing the obtained mixture A in a constant temperature water bath at 35°C, and after stirring for 1 hour, add 160ml of deionized water dropwise, and control the temperature of the system below 60°C to obtain mixture B;

[0065] c) Place the beaker containing the obtained mixture B in a 98°C water bath, stir for 30 minutes; add 300ml of deionized water to dilute, then add 15ml of hydrogen peroxide dropwise with a mass concentration of 30% and mix it with 5% hydrogen peroxide. Wash with hydrochloric acid and centrifuge 4 times (the rotating speed of each centrifu...

Embodiment 3

[0071] The graphene-supported zirconia composite material of the present embodiment is prepared by the following method:

[0072] 1) Preparation of graphene oxide dispersion:

[0073] a) At 1°C, add 0.25g of NaNO 3 Add 1.0g of graphite powder into 92ml of concentrated sulfuric acid, slowly add 5.0g of potassium permanganate, stir for 2h to react, and obtain mixture A;

[0074] b) Place the beaker containing the obtained mixture A in a constant temperature water bath at 35°C, and after stirring for 1 hour, add 80ml of deionized water dropwise, and control the temperature of the system below 50°C to obtain mixture B;

[0075] c) Place the beaker containing the obtained mixture B in a 97°C water bath and stir for 30 minutes; add 150ml of deionized water to dilute, then add 8ml of hydrogen peroxide dropwise with a mass concentration of 30% and mix it with 5% hydrogen peroxide Wash with hydrochloric acid and centrifuge 4 times (the rotating speed of pickling is 5000rpm for each c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com