Use method of inorganic dry powder heat insulation paint

A heat-insulating coating and inorganic dry powder technology, applied in cement coatings, coatings, etc., can solve problems such as service life of no more than 5-10 years, low building life, multiple maintenance, etc., to achieve good heat insulation effect, heat insulation The effect of stable performance and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

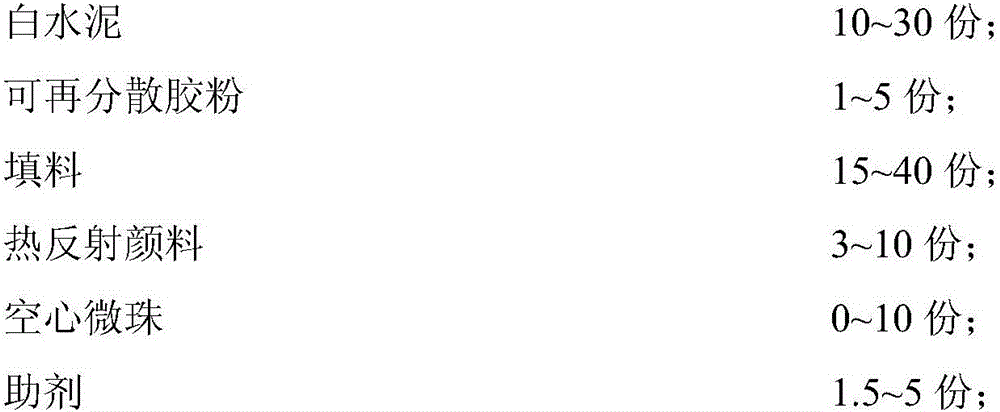

Method used

Image

Examples

Embodiment 1

[0034] Add 15 parts of white Portland cement, 3 parts of metakaolin, 4 parts of rutile titanium dioxide, 2 parts of iron oxide red, 1 part of cobalt blue, 10 parts of calcium carbonate, 8 parts of silicon micropowder, and 0.2 parts of water reducing agent into the dispersion equipment 0.3 parts of antifoaming agent, 1.3 parts of antibacterial agent, 0.3 parts of antifungal agent, 0.1 part of cellulose ether, 0.2 part of starch ether and 3 parts of redispersible rubber powder (acrylic acid copolymer), stir well and filter through a sieve , to obtain the inorganic dry powder thermal insulation coating product of the present invention.

[0035] Instructions:

[0036] (1) Take said inorganic dry powder heat-insulating coating and tap water respectively by the ratio of 1:0.8;

[0037] (2) Add water to the inorganic dry powder heat-insulating coating in batches twice, and stir for 5 minutes until the slurry-like coating is uniform;

[0038] (3) Apply the paste paint to the surface...

Embodiment 2

[0040] Add 10 parts of white sulphoaluminate cement, 2 parts of metakaolin, 6 parts of nickel titanium yellow, 2 parts of zinc sulfide, 4 parts of iron oxide yellow, 8 parts of calcium carbonate, 3 parts of diatomite, and 2 parts of silicon micropowder into the dispersion equipment. 1 part, 3 parts of hollow ceramic microspheres, 0.1 part of water reducer, 0.1 part of defoamer, 1 part of antibacterial agent, 0.2 part of antifungal agent, 0.1 part of cellulose ether and redispersible rubber powder (ethylene-vinyl acetate copolymer matter) 2 parts, stirred evenly and filtered through a sieve to obtain the inorganic dry powder thermal insulation coating product of the present invention.

[0041] Instructions:

[0042] (1) Take said inorganic dry powder heat-insulating coating and tap water respectively by the ratio of 1:1.2;

[0043] (2) Add water to the inorganic dry powder heat-insulating coating in batches for 3 times, and stir for 10 minutes to a uniform slurry coating;

[...

Embodiment 3

[0046] Add 25 parts of white aluminate cement, 4 parts of metakaolin, 2 parts of iron chrome black, 3 parts of copper chrome black, 8 parts of calcium carbonate, 10 parts of diatomite, 5 parts of microsilica powder, and hollow glass microspheres into the dispersion equipment 6 parts, 4 parts of hollow ceramic microspheres, 2 parts of antibacterial agent, 1 part of cellulose ether, 0.5 part of antifungal agent, 1 part of defoamer, 0.1 part of starch ether, 0.4 part of water reducing agent and redispersible rubber powder ( Vinyl acetate-ethylene tert-carbonate copolymer) 5 parts, stirred evenly and filtered through a sieve to obtain the inorganic dry powder thermal insulation coating product of the present invention.

[0047] Instructions:

[0048] (1) Take said inorganic dry powder heat-insulating coating and tap water respectively by the ratio of 1:0.4;

[0049] (2) Add water to the inorganic dry powder heat-insulating coating in batches for 3 times, and stir for 3 minutes un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com