Method for detecting urea based on metal organic framework material fluorescent sensor

A metal-organic framework and fluorescent sensor technology, applied in the field of analysis and detection, can solve the problems of large interference of coexisting substances, high false positive rate, cumbersome and time-consuming operation, etc., and achieve high specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

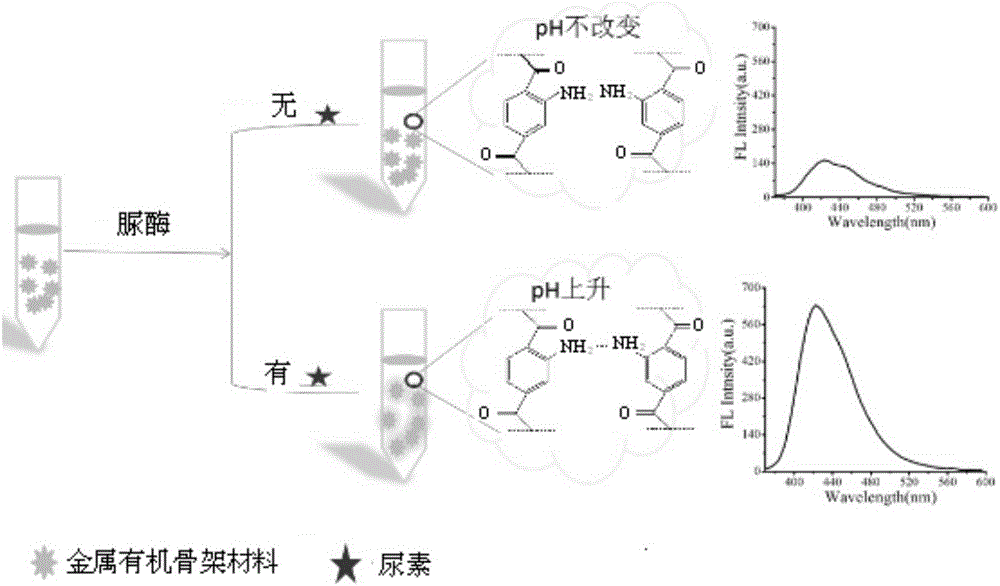

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

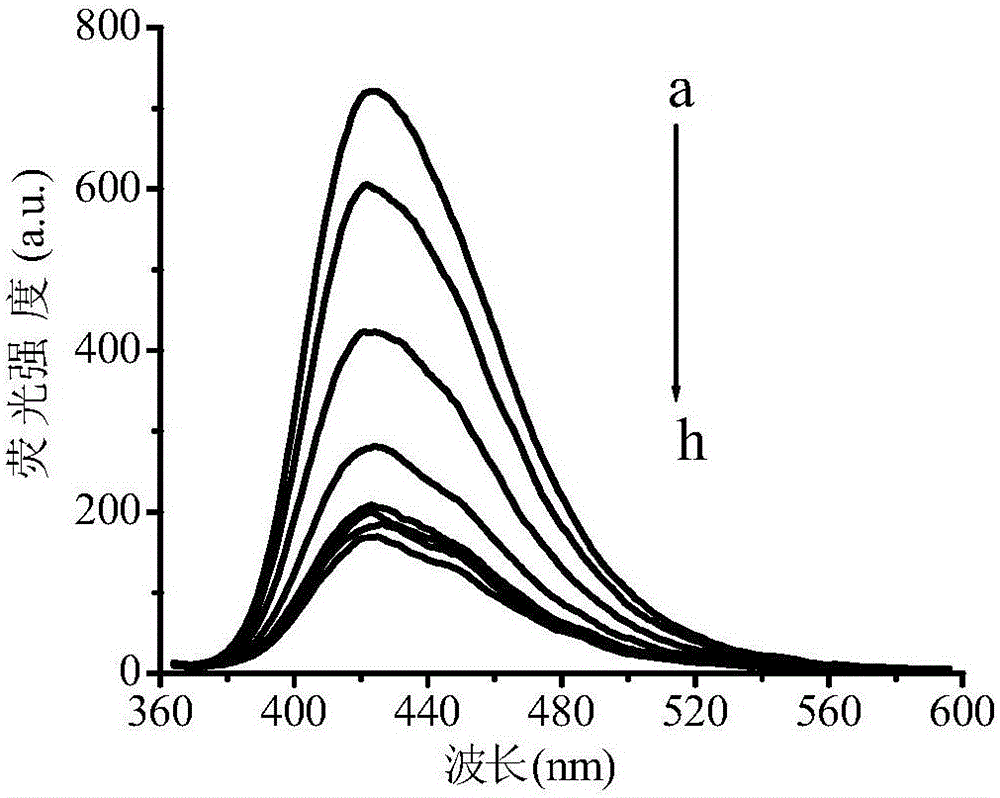

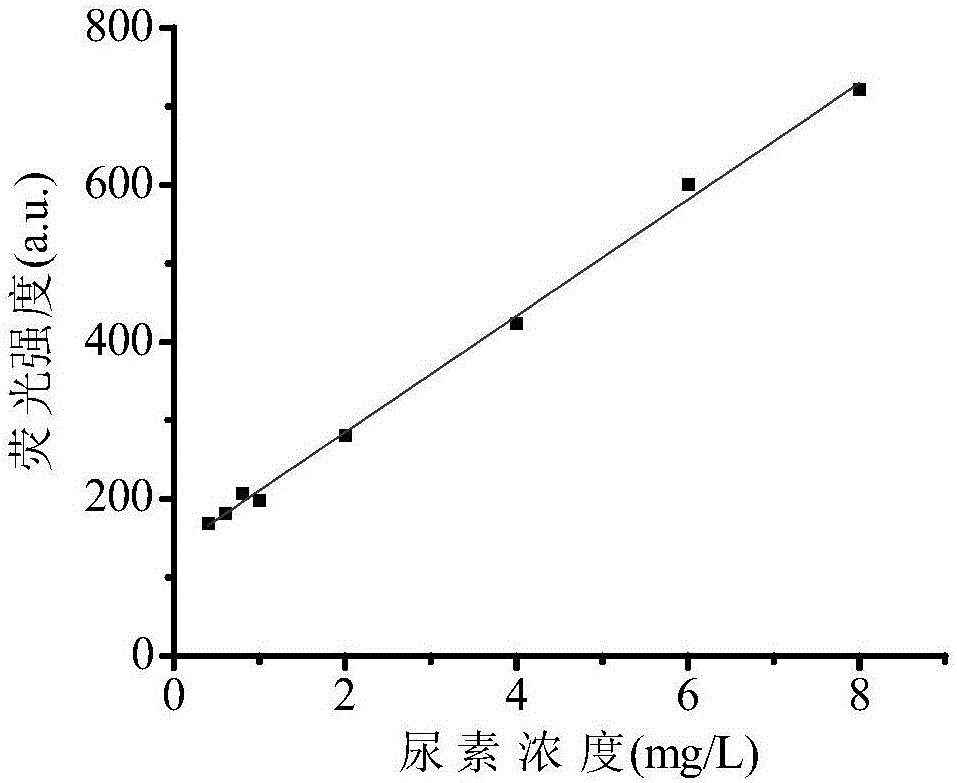

[0034] Embodiment 1 (the inventive method detects urea)

[0035] Synthesis of zirconium-containing organic framework material UiO-66-NH 2 , the process is as follows:

[0036] Step 1: ZrOCl 2 2.5H 2 O (0.645g, 2mmol), BDC-NH 2 (0.362g, 2mmol), benzoic acid (4.885g, 40mmo) and concentrated hydrochloric acid (12mol / L, 0.347mL) were ultrasonically dissolved in 34mL DMF, after dissolution, the solution was transferred to a 100mL Teflon-lined high pressure reaction kettle, put it in an oven, react at 120°C for 24 hours, then cool to room temperature, filter the product to obtain a yellow powder product, rinse with 20mL DMF and 10mL acetone three times, and dry at 80°C. spare.

[0037] Step 2: Put the solid powder obtained in step 1 in 20mL DMF and centrifuge for 12 hours (replace the solvent every 4 hours), then soak it in 10mL ethanol for 1 day (replace the solvent every 8 hours), and then dry it in a vacuum oven. Dry at 80°C for 20 hours to obtain the activated UiO-66-NH 2...

Embodiment 2

[0043] Embodiment 2 (application of the inventive method in detecting urea and other common coexisting substances)

[0044] For evaluating the specificity of the method of the present invention, common coexistence substance such as calcium ion Ca in the food is chosen 2+ , Potassium ion K + , Sodium ion Na + , glutamic acid Glu, bovine serum albumin BSA, lactose Lac and casein Casein, these substances are measured according to the detection steps described in Example 1, and the respective fluorescent signals are recorded and compared, the results are as follows image 3 shown. Since the target of urease is urea, the fluorescence signal of urea (6.0mg / L) is the strongest, and when the concentration of other coexisting substances (300mg / L) is 50 times that of urea, the fluorescence intensity is one-third of the urea signal or even lower. This result indicates that based on the metal-organic framework material UiO-66-NH 2 The method for detecting urea with a fluorescent sens...

Embodiment 3

[0045] Embodiment 3 (the inventive method is applied to the detection of urea in liquor)

[0046] Five liquor samples were purchased from local supermarkets, and 25 mL of the five liquor samples were put into five round-bottomed flasks, placed on a rotary evaporator, and evaporated to dryness at a temperature of 80 °C and a speed of 70-80 r / min. After the wine sample is completely evaporated to dryness, remove the flask, cool to room temperature, add 5 mL of distilled water, shake fully to wash out the residue, and filter the eluate through a 0.22 μm water phase filter membrane to obtain five parts of the treated sample liquid. Each sample was detected three times in parallel.

[0047] According to the analysis steps described in Example 1, the five processed liquor samples were detected respectively, and urea was detected in all five liquor samples, and the results are shown in Table 1.

[0048] Add different concentration (0.1mg / L~0.3mg / L) urea respectively in five parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com