A kind of perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of lowering cell performance, limiting application, destroying crystal structure, etc., and achieving the effects of improving electrical conductivity, good photoelectric performance, and promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1. Add an equal volume of 2mol / L HCl solution dropwise to a 0.46mol / L titanium isopropoxide solution, and stir magnetically at 800rpm for 10h to obtain TiO with a molar concentration of 0.23mol / L 2 Precursor solution;

[0067] 2. According to PbCl 2 :CH 3 NH 3 1:DMF=1.2mmol:3mmol:1mL ratio mixing, magnetic stirring at 800rpm speed at 50°C for 12h, the obtained mass concentration is a perovskite precursor solution of 45wt%;

[0068] 3. According to the ratio of 72.3g Spiro-OMeTAD, 28.8uL 4-tert-butylpyridine (TBP), 17.5uL lithium salt (Li-TFSI), dissolved in 1mL chlorobenzene solvent, mix them magnetically at a rate of 800rpm for 10h to obtain mole A hole transport layer precursor solution with a concentration of 0.17mol / L;

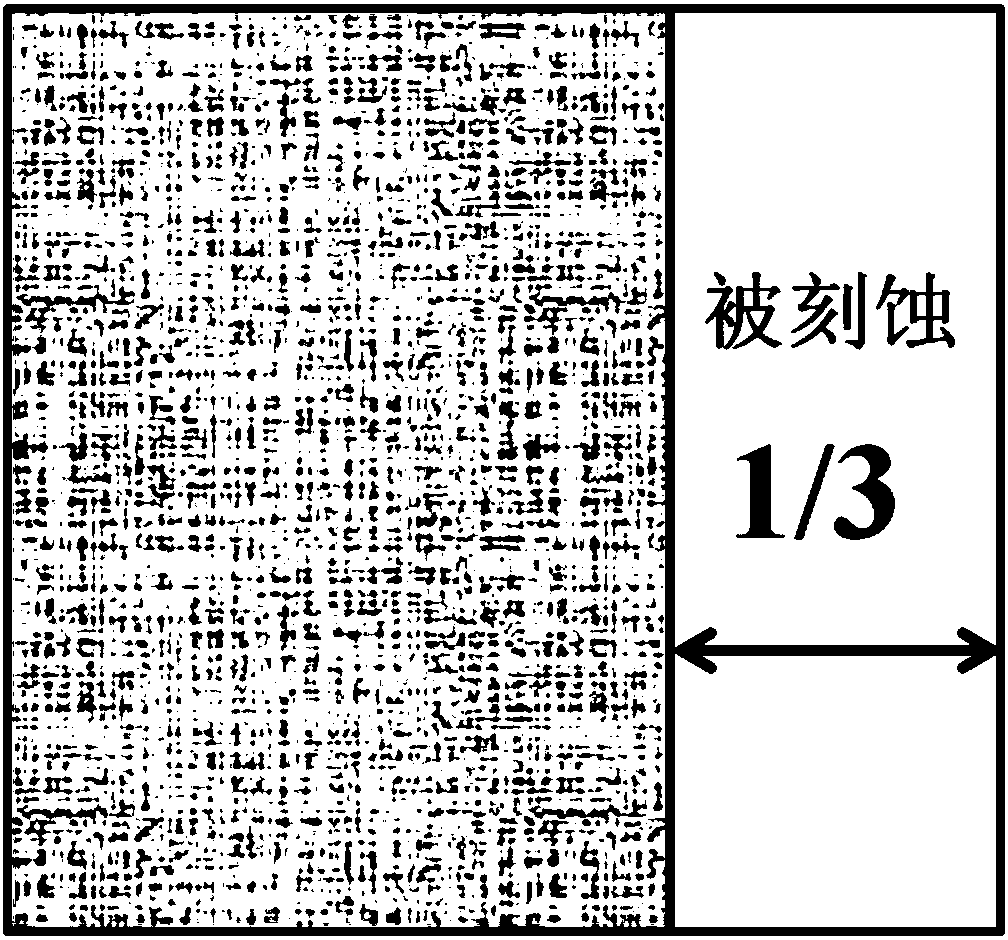

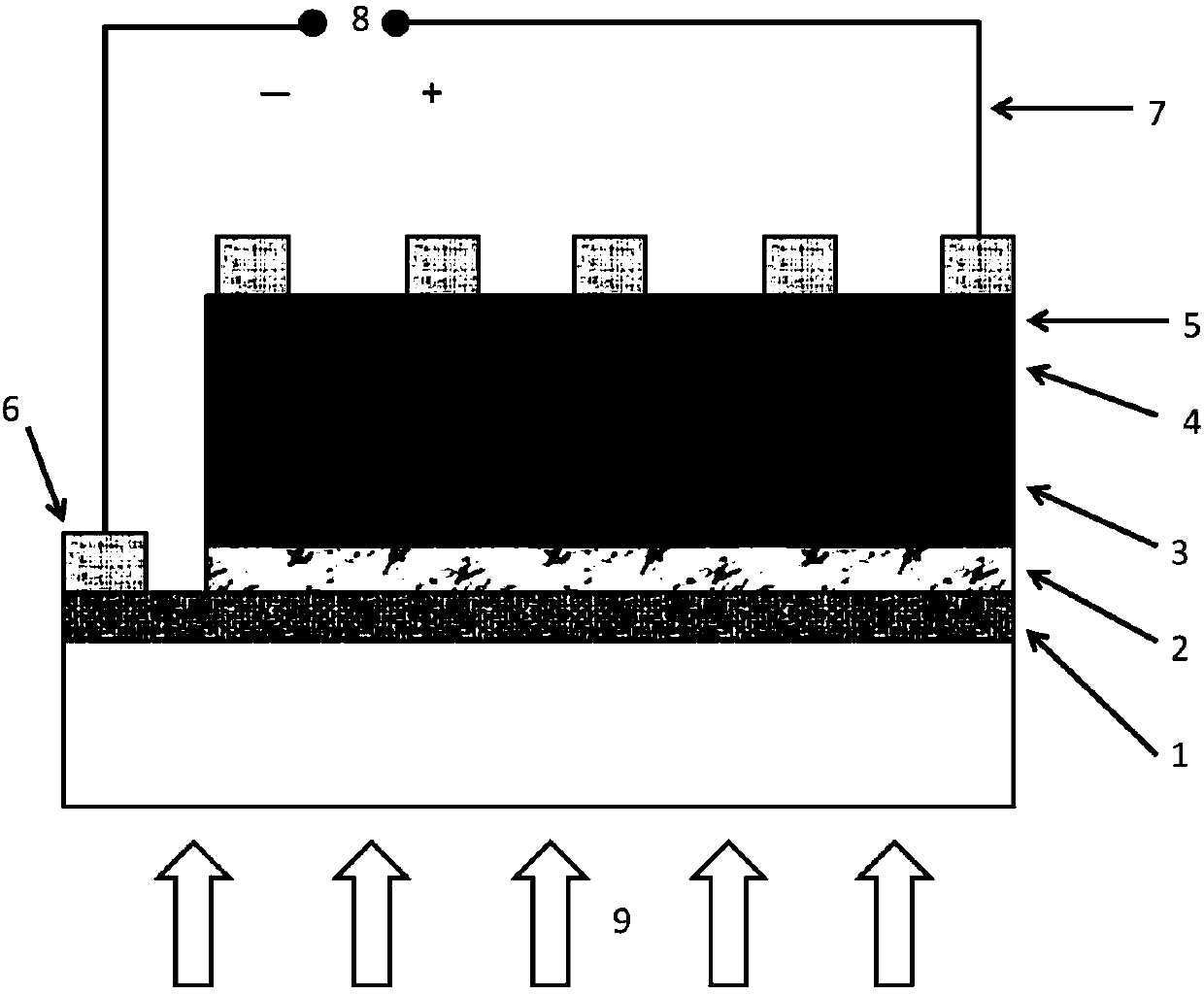

[0069] 4. Use FTO conductive glass with a surface sheet resistance of 7Ω / sq, a light transmittance greater than 85%, and an etching area of 1 / 3 of the total area as the substrate and transparent electrode 1, such as figure 1 shown;

[0070] ...

Embodiment 2

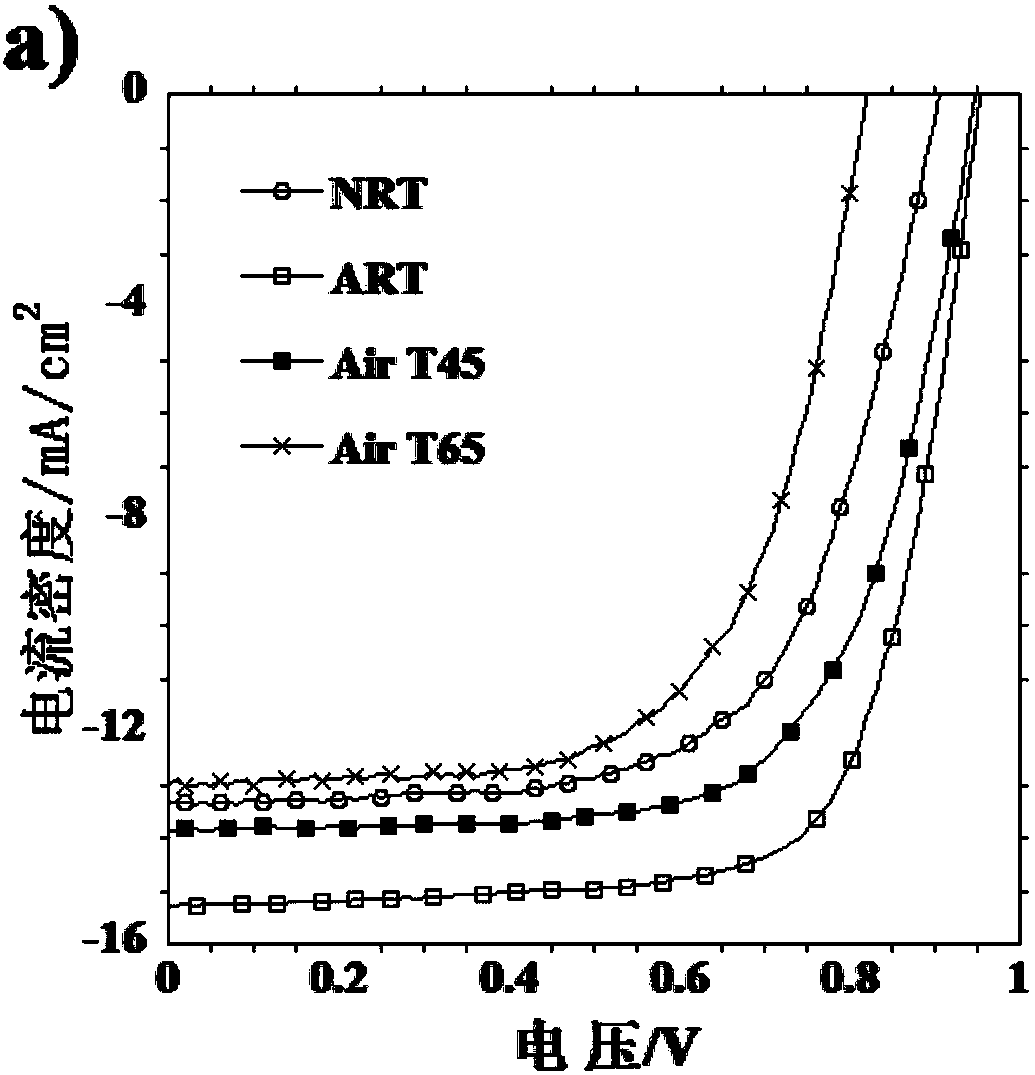

[0077] Using the same method as in Example 1, replace step 8 with: under normal pressure, with a flow rate of 3L / min, a relative humidity of 48% air flow at 45°C is stably blown vertically to the sample device after the hole transport layer is deposited 10h (implementation group for Air T45).

[0078] The perovskite solar cell prepared in this embodiment was tested by the same method as in Example 1, and the test results were as follows: image 3 , Figure 4 and shown in Table 1.

Embodiment 3

[0080] Using the same method as in Example 1, replace step 8 with: under normal pressure, with a flow rate of 3 L / min, a relative humidity of 48% of the 65 ° C air stream is stably blown vertically to the sample device after the hole transport layer is deposited 10h (implementation group for Air T65).

[0081] The perovskite solar cell prepared in this embodiment was tested by the same method as in Example 1, and the test results were as follows: image 3 , Figure 4 and shown in Table 1.

[0082] Table 1 Volt-ampere performance parameters of perovskite solar cells

[0083]

[0084] As can be seen from the above examples, the PCE of the perovskite solar cell prepared according to the preparation method provided by the present invention can reach up to 10.42%, the fill factor can reach more than 0.7, and the open circuit voltage V OC and short circuit current J SC Respectively up to 0.95V and 15.24mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com