Salt production method and salt production system

A technology of crystallization salt and crystallization, which is applied in the field of salt production methods and salt production systems, can solve the problems of limited membrane concentration recovery rate and difficult disposal of solid miscellaneous salt, achieve good economic value and use value, increase water recovery rate, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

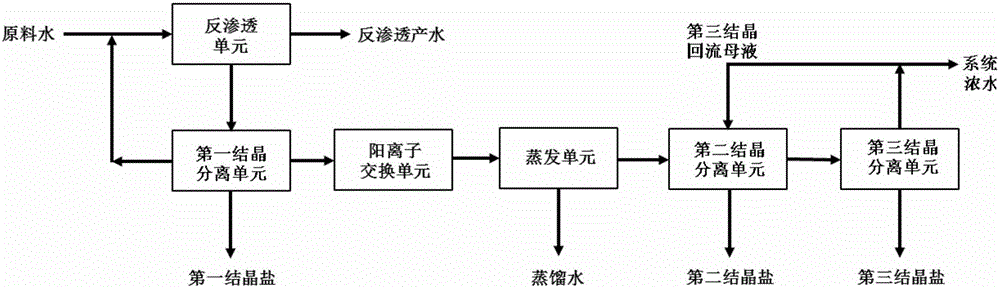

[0097] to combine figure 1 , the present embodiment is used to illustrate the salt making method of the present invention.

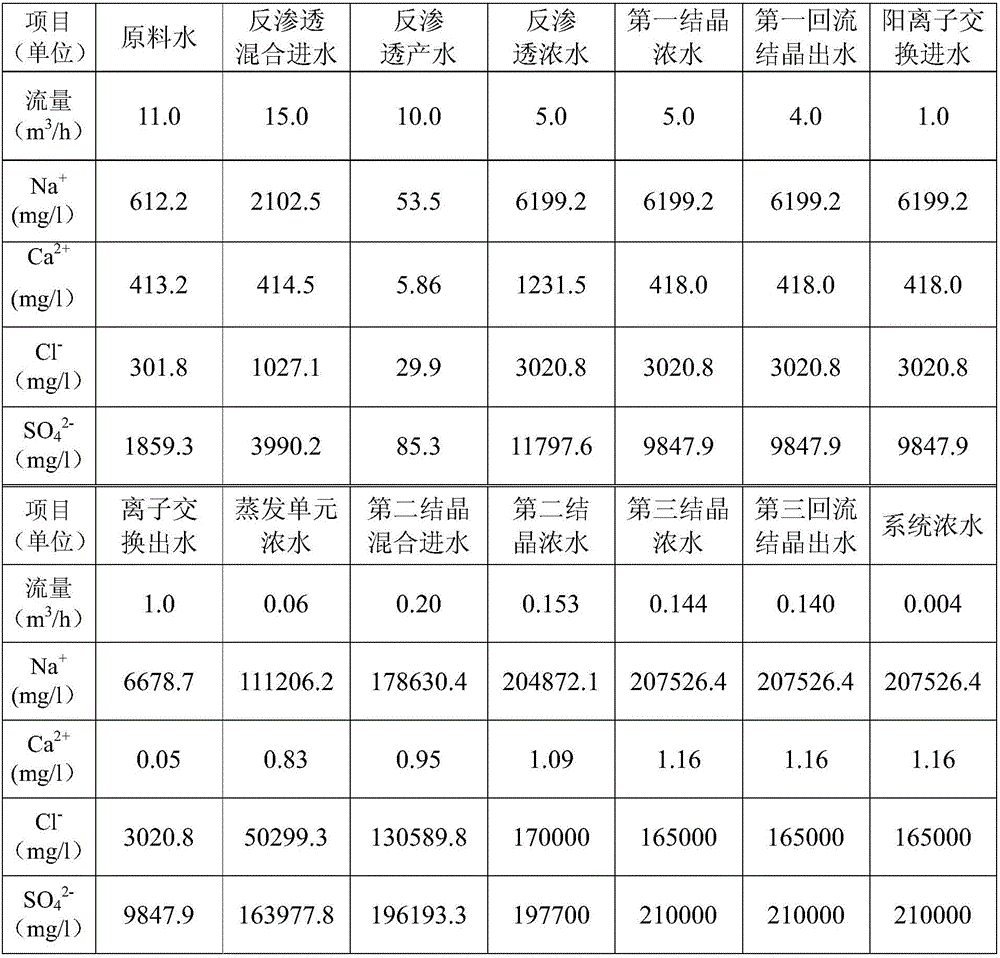

[0098] The reverse osmosis unit used in this embodiment is a one-stage one-stage reverse osmosis system including 3 parallel membrane shells, and 6 series-connected DOW BW30FR-400 reverse osmosis membrane elements are housed in each membrane shell; the first crystallization separation unit includes A total volume of 12.5m 3 The reaction clarifier and centrifugal separation device; the cation exchange unit is a volume of 0.15m 3 , A cation exchanger filled with DOWEXMAC-3 weak acid cation exchange resin; the evaporation unit is a heat exchange area of 20m 2 The mechanical compression evaporator; the second crystallization separation unit includes a heat exchange area of 1.0m 2 The forced circulation evaporation crystallizer and centrifugal separation device; the third crystallization separation unit includes a heat exchange area of 0.2m 2 The fo...

Embodiment 2

[0111] to combine figure 1 , the present embodiment is used to illustrate the salt making method of the present invention.

[0112] The reverse osmosis unit used in this embodiment is a one-stage one-stage reverse osmosis system including 3 parallel membrane shells, and 6 series-connected DOW BW30FR-400 reverse osmosis membrane elements are housed in each membrane shell; the first crystallization separation unit includes A total volume of 12.5m 3 The reaction clarifier and centrifugal separation device; the cation exchange unit is a volume of 0.15m 3 , A cation exchanger filled with DOWEXMAC-3 weak acid cation exchange resin; the evaporation unit is a heat exchange area of 20m 2 The mechanical compression evaporator; the second crystallization separation unit includes a volume of 0.15m with insulation layer 3 stainless steel container and centrifugal separation device; the third crystallization separation unit includes a heat exchange area of 1.0m 2 The forced circulat...

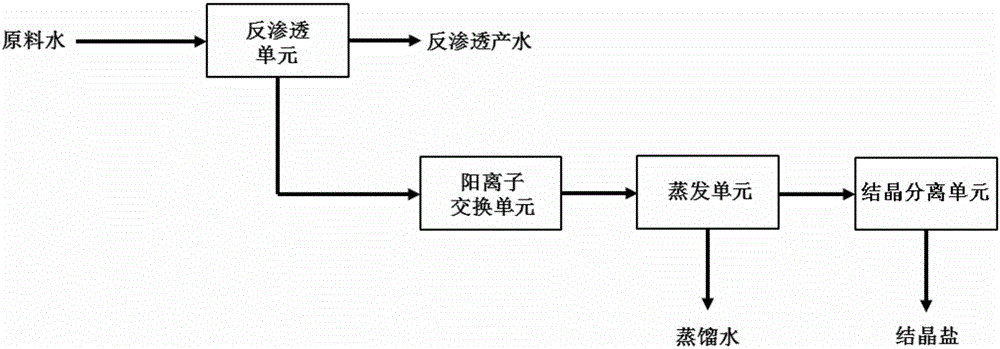

Embodiment 3

[0126] According to the method of Example 2, the difference is that in step (6), all the third crystal concentrated water is supplied to the evaporative crystallizer as the system concentrated water for evaporative crystallization treatment, specifically, step (5) and step (6 )for:

[0127] (5) Set the flow rate to 0.06m 3 / h, the concentrated water of the evaporation unit with a temperature of 105°C is cooled to 0°C by a spiral tube heat exchanger, and then supplied to the second crystallization separation unit as the second crystallization feed water, and the cooling crystallization separation process is carried out at 0°C. Because the solubility of sodium sulfate drops sharply at low temperature, part of sodium sulfate is separated out, adopts centrifugal separation device to carry out centrifugation after processing, obtains sodium sulfate crystalline salt (after deducting crystal water, is 11.6kg / h). At the same time, the obtained flow rate is 0.06m 3 / h, the second cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com