Method for preparing polycarboxylate superplasticizer with main chain modified isocyanate grafted positive ion side chain

A technology of isocyanate and cation, applied in the field of cationic side chain type polycarboxylate water reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

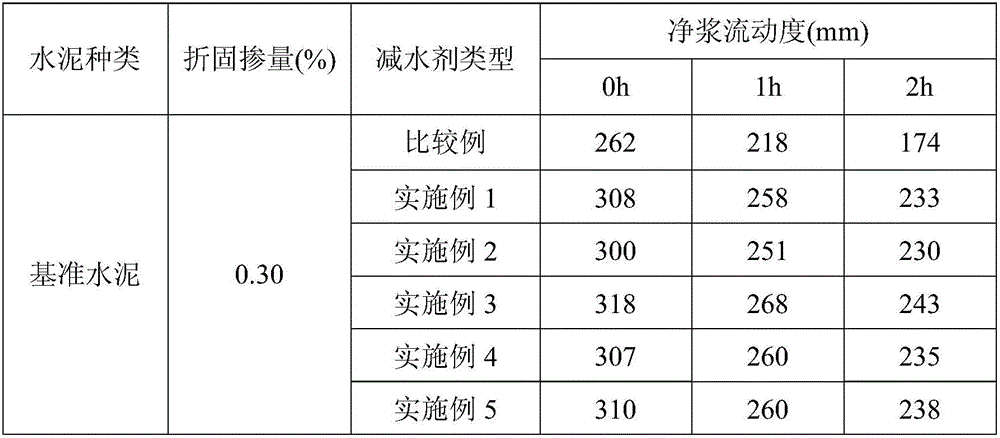

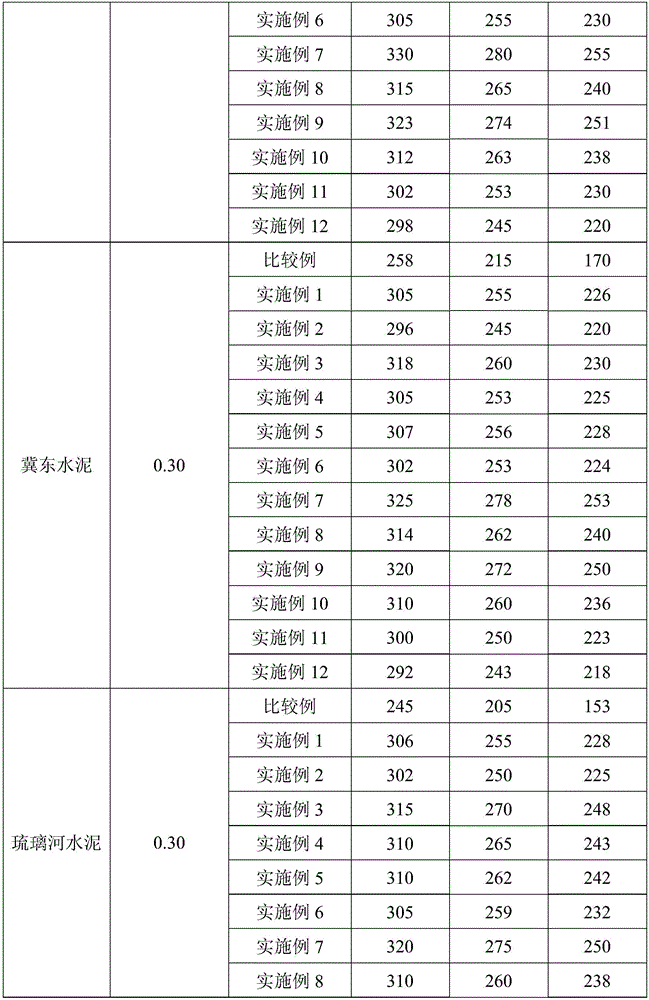

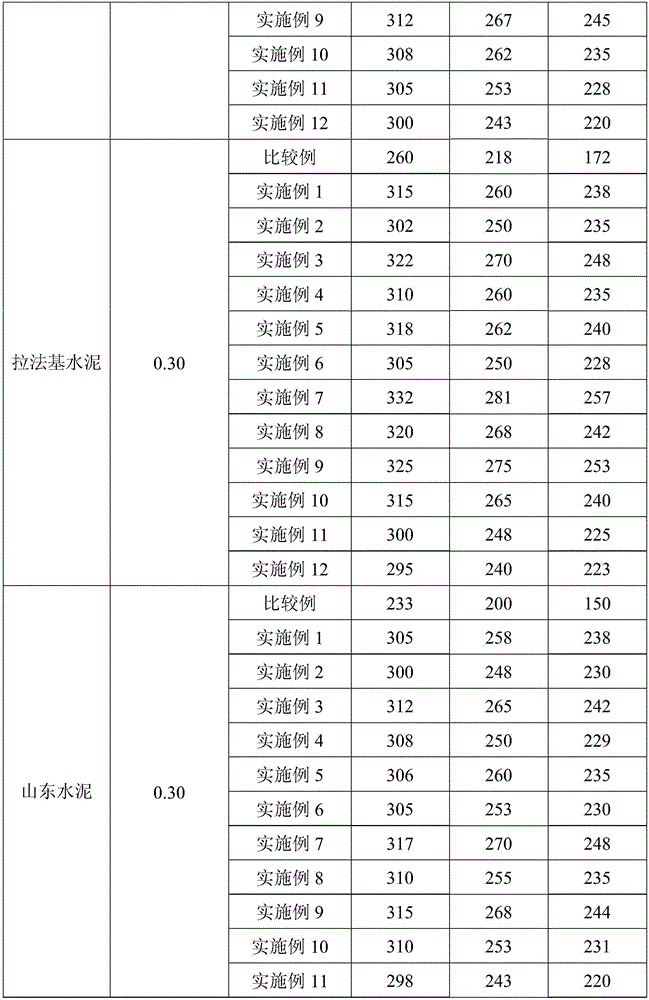

Examples

Embodiment 1

[0029] First, 4.8g of acrylic acid, 3.87g of fumaric acid, 1.07g of acrylamide, 17.53g of water, 1.57g of mercaptoacetic acid, and 31.09g of a 2% potassium persulfate aqueous solution were successively added to the reactor, and each feeding interval was stirred. The time is 15 minutes, and the temperature is raised to 55°C for polymerization reaction, and the reaction is 6 hours to obtain the aqueous solution of polycarboxylic acid-amide; the aqueous solution of the obtained product polycarboxylic acid-amide is vacuumed to remove the moisture in the system, and 3.13 g of sodium hypochlorite and 0.6 The mixed solution of sodium hydroxide was stirred for 5 minutes, and reacted at a constant temperature of 35°C for 1.5 hours to obtain polycarboxylic acid-isocyanate; 88.26g of methacryloyloxyethyl dimethyl butyl Ammonium bromide and 0.53 n-pentanol, then add 799.1g water and be mixed with the aqueous solution that mass concentration is 10%, the reactor is filled with nitrogen and i...

Embodiment 2

[0031] After the polycarboxylate superplasticizer solution with a mass fraction of 50% obtained in Example 1 was stored at 6° C. for 20 days, its implementation effect was measured.

Embodiment 3

[0033] First add 0.66g acrylic acid, 11.83g itaconic acid, 1.85g acrylamide, 28.6558g water, 2.39g sodium methylpropene sulfonate, 30g mass fraction in the reactor successively and be 1% sodium persulfate aqueous solution, and each time Stir for 20 minutes between additions, heat up to 75°C for polymerization reaction, and react for 4 hours to obtain an aqueous solution of polycarboxylic acid-amide; vacuumize the aqueous solution of the obtained product polycarboxylic acid-amide to remove moisture in the system, and add 5.81g The mixed solution of sodium hypochlorite and 1.04g sodium hydroxide was stirred for 12 minutes, and reacted at a constant temperature of 50°C for 1 hour to obtain polycarboxylic acid-isocyanate; in another reactor, 73.56g dimethyldiallyl chloride was added Ammonium and 0.96 n-butanol, then add 894.28g of water to prepare an aqueous solution with a mass concentration of 7.69%. The reactor is filled with nitrogen for 5 times to remove oxygen and then sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com