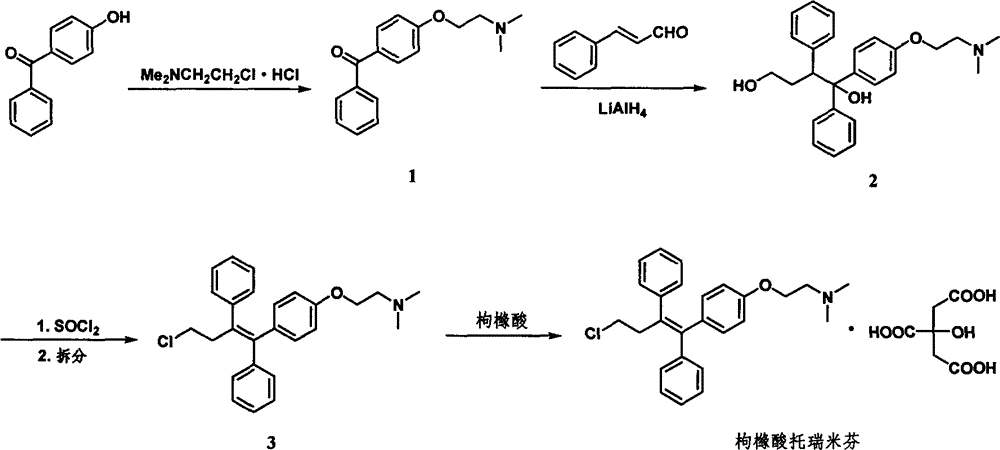

New preparation method of citric acid toremifene intermediate

A technology of toremifene citrate and an intermediate, which is applied in the field of medicine and chemical industry, can solve the problems of water pollution, complicated operation, reduced yield and the like, and achieves the effects of ensuring health, increasing reaction temperature and reducing solid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 10L three-necked flask equipped with mechanical stirring, add 400 g of 4-hydroxybenzophenone, 696 g of potassium carbonate, 5.4 kg of toluene, and 140 g of 95% industrial ethanol, and stir at 53-58° C. for 1 hour. After cooling to below 40°C, 436 g of N,N-dimethylaminochloroethane hydrochloride was added, and the temperature was raised to 80-85°C to react for 4 hours. TLC monitors that the conversion of the raw material 4-hydroxybenzophenone is basically complete, cools to below 40° C., adds 2.4 kg of drinking water, stirs, separates layers, and discards the lower aqueous phase. The toluene layer was washed three times with 4.6 liters of 4% sodium hydroxide solution, and then washed twice with 2 liters of drinking water. The solvent was distilled off under reduced pressure at 55-60°C to obtain 521 g of a light yellow oil, which was cooled to obtain a light yellow solid, and the yield of Intermediate 1 was 95.8%.

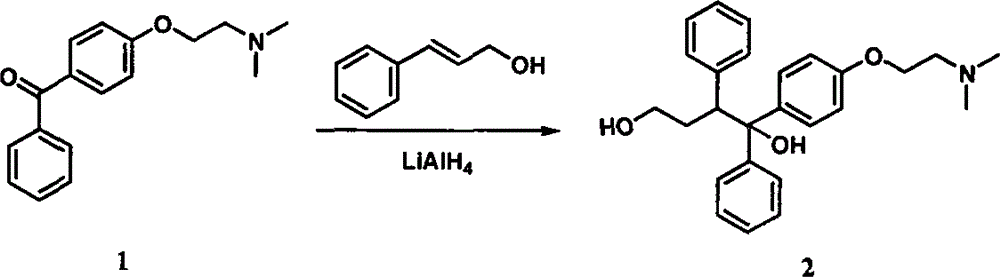

Embodiment 2

[0020] Throw 1.2kg of tetrahydrofuran and 54g of tetrahydrofuran into a 5L three-necked bottle, control the temperature at 20-28°C, slowly add the tetrahydrofuran solution of cinnamaldehyde (containing 318g of cinnamaldehyde, 960g of tetrahydrofuran) dropwise. Stir for 45 minutes. A solution of intermediate 1 in tetrahydrofuran (containing 465 g of intermediate 1, 1.2 kg of tetrahydrofuran) was added at this temperature. After the addition is complete, stir at 38-43°C for 1 hour. Transfer the reaction solution to a 20-liter glass reactor, add 7 L of tetrahydrofuran, slowly add 132 g of 20% sodium hydroxide solution dropwise, stir for 10 minutes, add 960 g of anhydrous sodium sulfate, and then add dropwise of 132 g of drinking water. Stir for half an hour and filter with suction. The filter cake was washed with 1 L of tetrahydrofuran. Tetrahydrofuran was distilled off under reduced pressure, 2.64kg of toluene was added, heated to 90-100°C to dissolve, slowly cooled to room t...

Embodiment 3

[0022] Put 1080kg of toluene, 28kg of 95% industrial ethanol, 140kg of potassium carbonate, and 80kg of 4-hydroxybenzophenone into a 2000L glass-lined reactor, and stir for 1 hour at 53-58°C. The temperature was lowered to below 40°C, and 87.5 kg of N,N-dimethylaminochloroethane hydrochloride was added under the protection of nitrogen. After the injection was completed, the temperature was slowly raised to 80-85°C and stirred for 4 hours. Cool down to below 40°C, add 500kg of drinking water, stir for 15 minutes, and let stand to separate layers. The upper organic phase was washed three times with 900kg of 4% aqueous sodium hydroxide solution, and the organic phase was washed twice with 800kg of drinking water. The solvent was concentrated under reduced pressure until no distillate was evaporated under the conditions of vacuum degree not lower than 0.085MPa and internal temperature not higher than 80°C to obtain 105.5kg of oily substance, which was light yellow solid after cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com