Industrial liquid fermentation method of bacillus cereus JZBC1 for dissolving pond dinoflagellate

A technology of Bacillus cereus and liquid fermentation, which is applied in the field of microbial preparations and can solve problems such as unseen industrial production products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

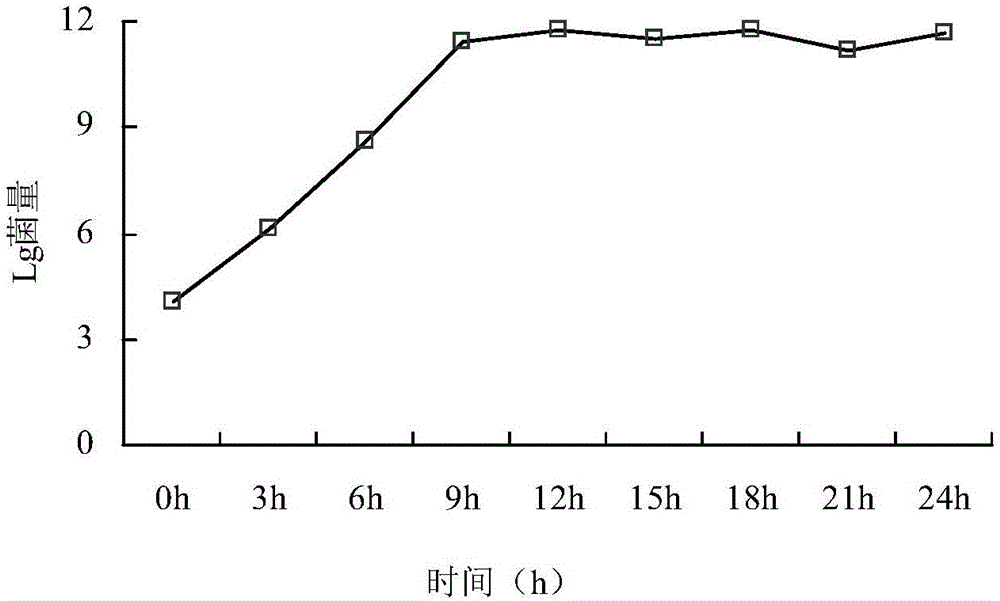

[0035] The Establishment of Industrialized Liquid Fermentation Parameters of Bacteria

[0036] Using the 50L fermenter system platform to study and establish the process parameters of the industrialized liquid fermentation of bacterial agents. The growth rate of Bacillus cereus JZBC1, the rate of spore formation, and the algae-lysis efficiency of the fermentation agent were used as evaluation indicators to establish and optimize the fermentation parameters. The obtained relevant fermentation parameters can be applied to the 50L-500L-5000L step-by-step fermentation system platform to carry out the industrialized expanded fermentation culture of the JZBC1 strain.

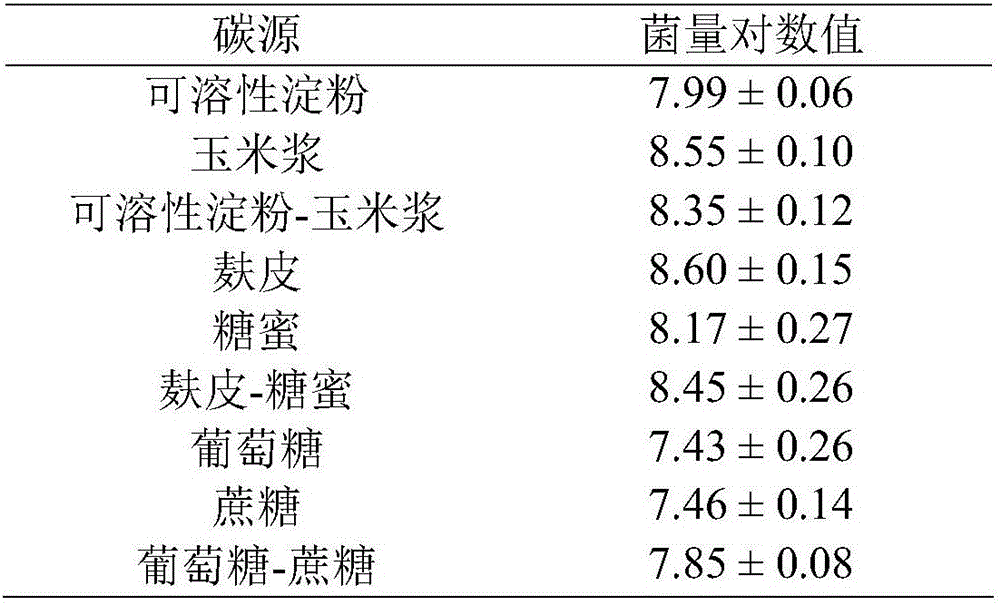

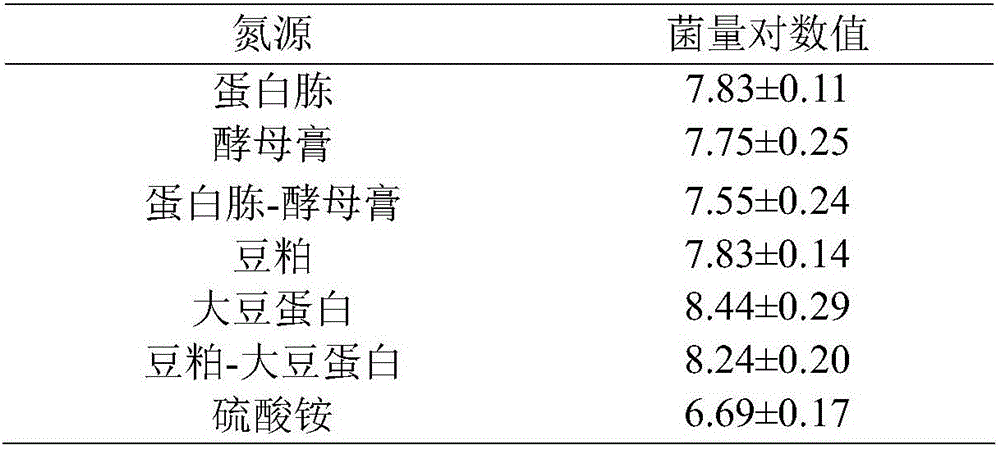

[0037] First, using the single factor test method, on the basis of the basic fermentation medium, different carbon sources (sucrose, glucose + sucrose, soluble starch, molasses, corn steep liquor, bran, bran + molasses, soluble starch + corn steep liquor) were selected. ) to replace the glucose in the basal medium in...

Embodiment 2

[0048] The industrialized liquid fermentation production of Bacillus cereus JZBC1 was carried out in the Huadu Microbial Industrial Fermentation Experimental Plant of the South China Sea Fisheries Research Institute of the Chinese Academy of Fishery Sciences in Huadu District, Guangzhou City. The fermentation system is an industrialized liquid fermentation system of 50L-500L-5000L.

[0049] (1) The Bacillus cereus JZBC1 strain was activated with a nutrient broth medium liquid medium to prepare a seed solution, pH 6.00-7.50, 200-240 rpm, 28-32°C constant temperature shaking culture for 20-30 hours.

[0050] (2) The formulation of the fermentation medium contains 20g of corn steep liquor, 13.5g of soybean protein, 1g of NaCl, and KH in 1L of water. 2 PO 4 0.2g, MgSO 4 0.2g, CaCl 2 0.1g, MnSO with a mass percentage of 3% 4 Solution 1mL, prepare the required culture medium in the fermenter according to the above formula by 70% liquid volume.

[0051] (3) Turn on the heating ...

Embodiment 3

[0057] Different from Example 2, the formula of the fermentation medium is: 1L water contains corn steep liquor 18.5g, soybean protein 0g, NaCl 0.8g, KH 2 PO 4 0.4g, MgSO 4 0.15g, CaCl 2 0.3g, MnSO with a mass percentage of 3% 4 Solution 1 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com