Method for preparing organic microchannel plate by employing MEMS technology

A technology of micro-channel plate and micro-channel, which is applied in micro-electro-mechanical system technology and semiconductor fields, can solve the problems of dielectric loss affecting the dynamic uniformity of gain, etc., and achieve the effect of improving gain uniformity, increasing amplitude, and improving characteristic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

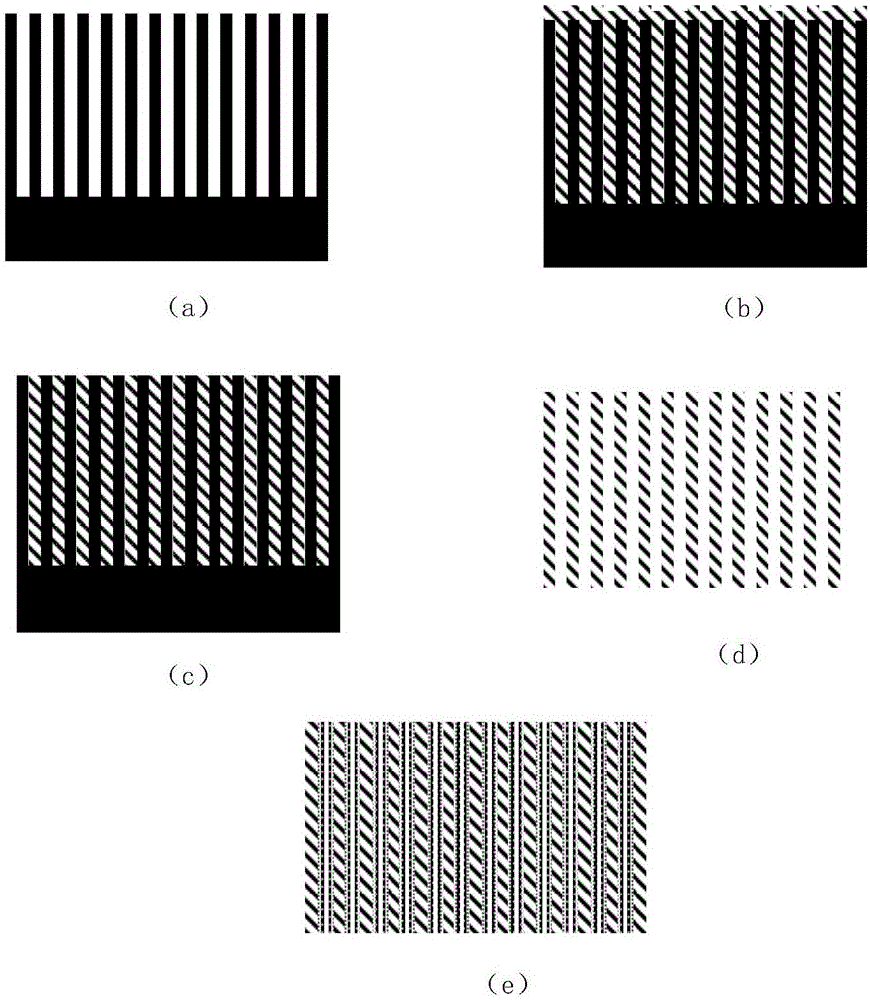

Image

Examples

Embodiment Construction

[0042] The present invention is a method for preparing an organic microchannel plate using MEMS technology, which includes the following steps:

[0043] 1) Using MEMS technology to prepare a silicon-based substrate with a high aspect ratio structure; the high aspect ratio structure is a columnar structure; the preparation adopts dry etching or electrochemical wet etching; the dry etching is specifically: using a mask Membrane material, the microporous structure is etched by reactive ion etching or plasma coupled etching;

[0044] The specific electrochemical wet etching is: the inverted pyramid shape is corroded by KOH, and the treated silicon wafer is electrochemically etched by an anodic oxidation solution composed of HF, tetramethylformamide, hydrochloric acid and an active agent;

[0045] The columnar structure with high aspect ratio prepares a layer of aluminum oxide on the surface of the silicon substrate through the ALD process, which acts as a barrier layer. The aluminum oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com