Special fertilizer for cotton

A special fertilizer and base fertilizer technology for cotton, applied in the fields of application, nitrogen fertilizer, potassium fertilizer, etc., can solve the problems that affect the physical and mental health of cotton, water source, soil and crop pollution, and drug resistance of pests and diseases, so as to improve photosynthesis and promote metabolism , the effect of preventing defoliation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

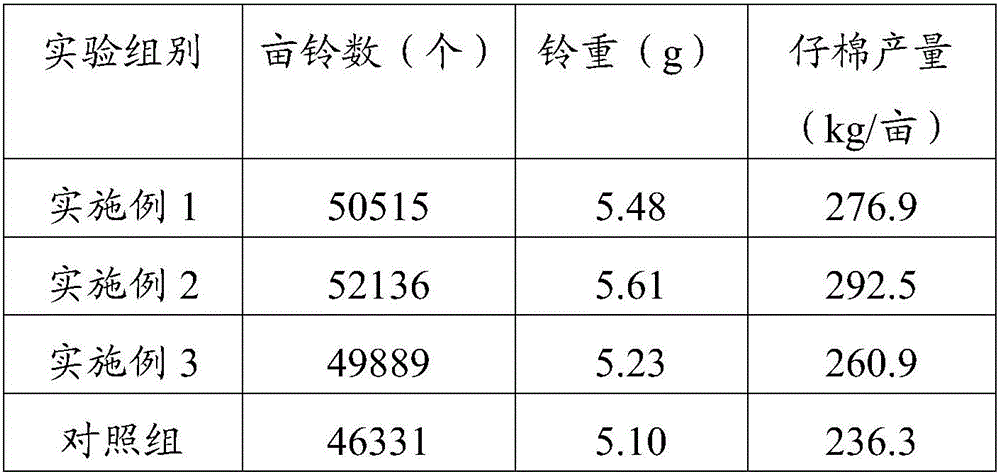

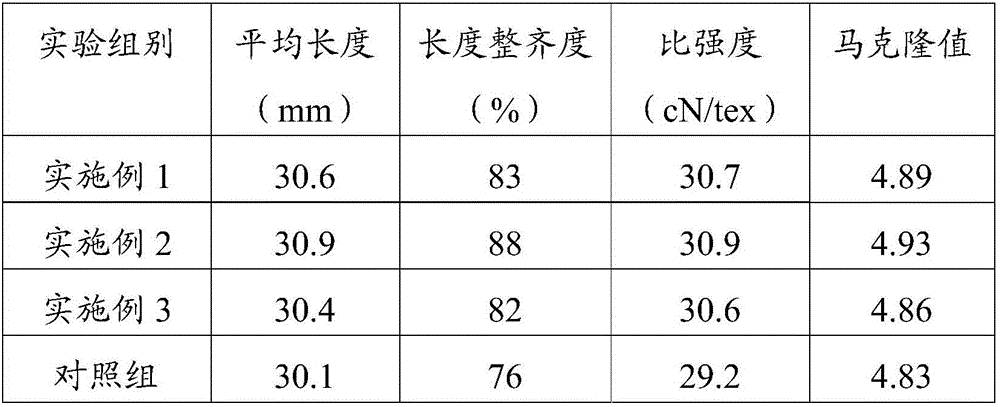

Examples

preparation example Construction

[0035] Specifically, the preparation method of the base fertilizer comprises the steps of:

[0036] After drying nitrogen, phosphorus and potassium compound fertilizer, medium and trace elements, sepiolite, quicklime, and attapulgite, they are uniformly mixed, crushed, and passed through a sieve of 80 to 100 meshes to obtain a spare material 1;

[0037] After pulverizing the organic fertilizer, pass it through a 80-100 mesh sieve to obtain the spare material 2;

[0038] The standby material 1 and the standby material 2 are uniformly mixed in a mixer, heated to 60-70° C., dried and sent to a granulator for granulation to obtain a base fertilizer.

[0039] Further, the first topdressing fertilizer includes the following components in parts by mass: 170-180 parts of urea, 145-155 parts of diamine phosphate, 146-152 parts of potassium chloride, 1.5-1.8 parts of ferrous sulfate, sulfuric acid Zinc 1.2-1.6 parts, EDTA chelated manganese 1.2-1.6 parts, borax 1.4-1.8 parts, ammonium ...

Embodiment 1

[0064]Special fertilizer for cotton, the base fertilizer includes the following components by mass: 10.8 parts of urea, 13 parts of superphosphate, 6.5 parts of potassium sulfate, 5 parts of medium and trace elements, 12 parts of sepiolite, 2 parts of quicklime, and 5 parts of attapulgite powder , 3 parts of activated carbon and 100 parts of organic fertilizer; the first topdressing fertilizer includes the following components by mass: 160 parts of urea, 140 parts of diamine phosphate, 140 parts of potassium chloride, 1 part of ferrous sulfate, and 1 part of zinc sulfate , 1 part of EDTA chelated manganese, 1 part of borax, 0.1 part of ammonium molybdate, 100 parts of cotton straw powder, 180 parts of animal manure, 3 parts of fertilizer starter, 10 parts of sodium alginate, 30 parts of zeolite powder, and 0.3 parts of plant regulator 2 parts, 2 parts of turmeric, 2 parts of azadirachtin and 3 parts of matrine; the second topdressing fertilizer includes each component of the fo...

Embodiment 2

[0066] Special fertilizer for cotton, the base fertilizer includes the following components by mass: 11.5 parts of urea, 13.8 parts of superphosphate, 6.9 parts of potassium sulfate, 6 parts of medium and trace elements, 15 parts of sepiolite, 2.5 parts of quicklime, 5.2 parts of attapulgite powder , 3.2 parts of activated carbon and 120 parts of organic fertilizer; the first topdressing fertilizer includes the following components by mass: 170 parts of urea, 150 parts of diamine phosphate, 150 parts of potassium chloride, 1.5 parts of ferrous sulfate, and 1.2 parts of zinc sulfate , 1.2 parts of EDTA chelated manganese, 1.4 parts of borax, 0.1 parts of ammonium molybdate, 120 parts of cotton straw powder, 200 parts of animal manure, 3.5 parts of fertilizer starter, 12 parts of sodium alginate, 35 parts of zeolite powder, and 0.4 parts of plant regulator parts, 2 parts of turmeric, 3 parts of azadirachtin and 4 parts of matrine; the second topdressing fertilizer includes each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com