High-strength weather-resistance and flame-retardance EPDM cable material

An EPDM, high-strength technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of elasticity, flame retardancy, wear resistance, ozone erosion resistance, weather resistance and other performance problems, and achieve good oxidation resistance, Effect of improving wettability and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

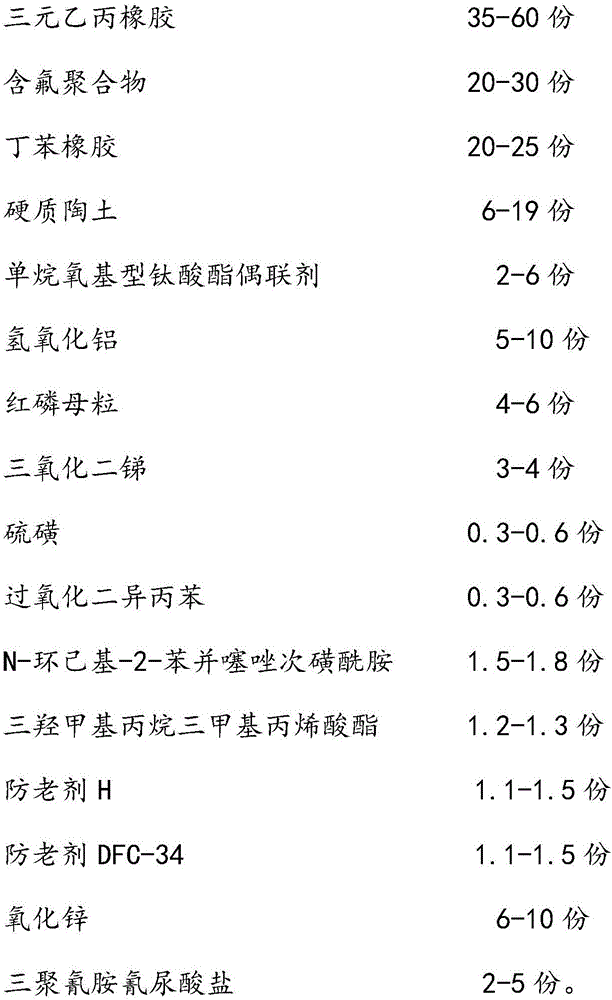

[0031] A high-strength weather-resistant and flame-retardant EPDM cable material proposed by the present invention, its raw materials include by weight: 35 parts of EPDM rubber, 20 parts of fluoropolymer, 20 parts of styrene-butadiene rubber, and 6 parts of hard clay , 2 parts of monoalkoxy titanate coupling agent, 5 parts of aluminum hydroxide, 4 parts of red phosphorus masterbatch, 3 parts of antimony trioxide, 0.3 part of sulfur, 0.3 part of dicumyl peroxide, N - 1.5 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.2 parts of trimethylolpropane trimethacrylate, 1.1 parts of antioxidant H, 1.1 parts of antioxidant DFC-34, 6 parts of zinc oxide, melamine cyanurate 2 parts of acid salt; wherein, the content of styrene in styrene-butadiene rubber is 30wt%; the solvent is made by mixing toluene and acetone at a volume ratio of 1:3.

[0032] During the preparation of fluoropolymers:

[0033] Add 45 parts of solvent, 12 parts of vinyl acetate, 14 parts of n-butanol, 13 parts of...

Embodiment 2

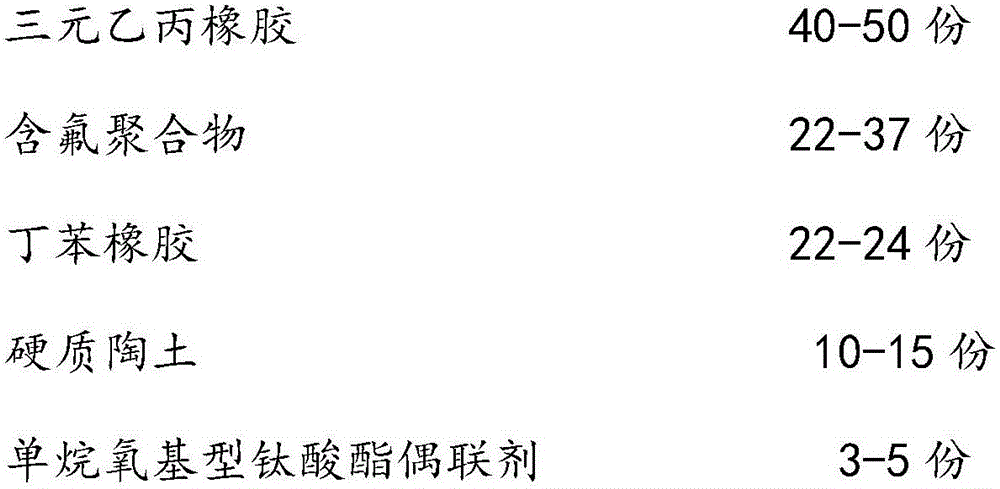

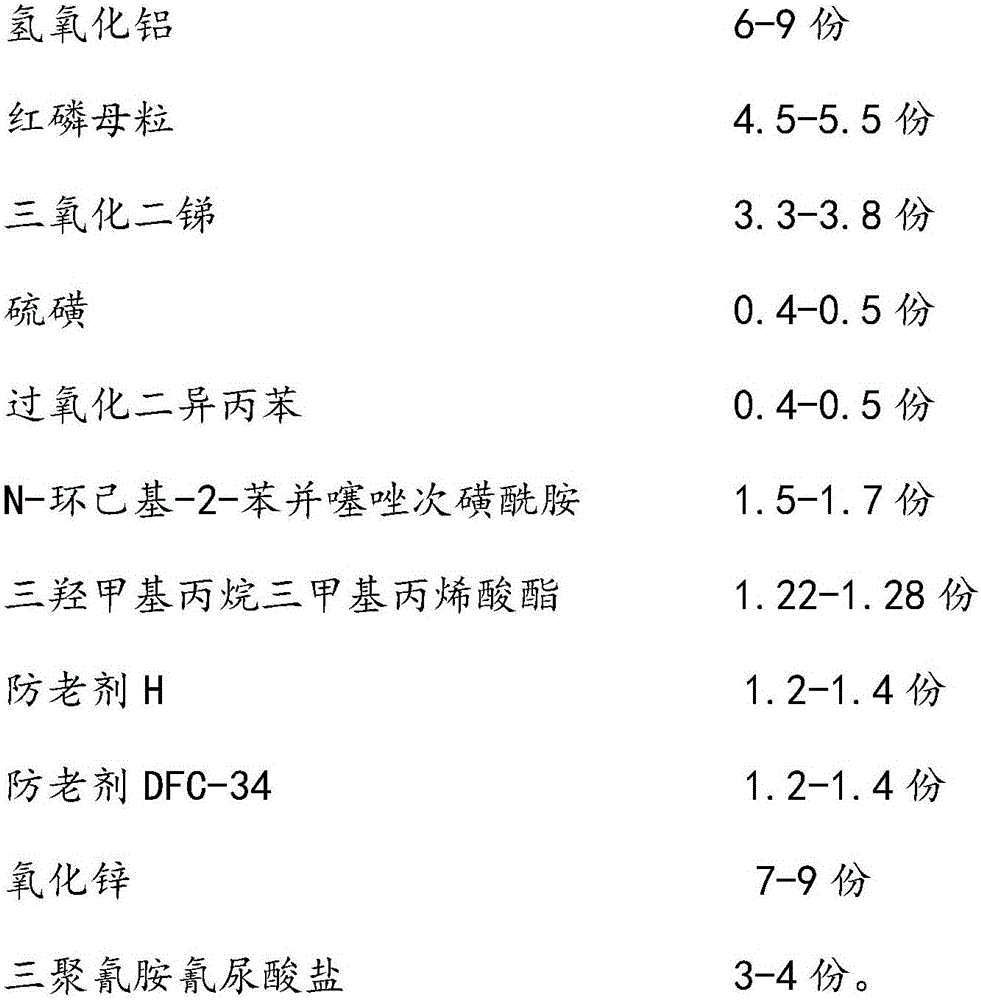

[0037] The present invention proposes a high-strength weather-resistant and flame-retardant EPDM cable material. The raw materials include: 45 parts of EPDM rubber, 25 parts of fluoropolymer, 23 parts of styrene-butadiene rubber, and 12 parts of hard clay. , 4 parts of monoalkoxy titanate coupling agent, 8 parts of aluminum hydroxide, 5 parts of red phosphorus masterbatch, 3.5 parts of antimony trioxide, 0.5 part of sulfur, 0.5 part of dicumyl peroxide, N- 1.6 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.25 parts of trimethylolpropane trimethacrylate, 1.3 parts of anti-aging agent H, 1.3 parts of anti-aging agent DFC-34, 8 parts of zinc oxide, melamine cyanuric acid 4 parts of salt; among them, the content of styrene in styrene-butadiene rubber is 30wt%; the solvent is made by mixing toluene and acetone at a volume ratio of 1:3.

[0038] During the preparation of fluoropolymers:

[0039] Add 46 parts of solvents, 13 parts of vinyl acetate, 15 parts of n-butanol, 14 part...

Embodiment 3

[0043] The present invention proposes a high-strength weather-resistant and flame-retardant EPDM cable material. The raw materials include: 40 parts of EPDM rubber, 22 parts of fluoropolymer, 23 parts of styrene-butadiene rubber, and 10 parts of hard clay , 3 parts of monoalkoxy titanate coupling agent, 7 parts of aluminum hydroxide, 5 parts of red phosphorus masterbatch, 4 parts of antimony trioxide, 0.4 part of sulfur, 0.5 part of dicumyl peroxide, N- 1.6 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.3 parts of trimethylolpropane trimethacrylate, 1.3 parts of anti-aging agent H, 1.2 parts of anti-aging agent DFC-34, 7 parts of zinc oxide, melamine cyanuric acid 4 parts of salt; among them, the content of styrene in styrene-butadiene rubber is 30wt%; the solvent is made by mixing toluene and acetone at a volume ratio of 1:3.

[0044] During the preparation of fluoropolymers:

[0045] 47 parts of solvents, 13 parts of vinyl acetate, 16 parts of n-butanol, 14 parts of oxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com