Graphene-coated lithium iron phosphate positive electrode material and preparation method thereof

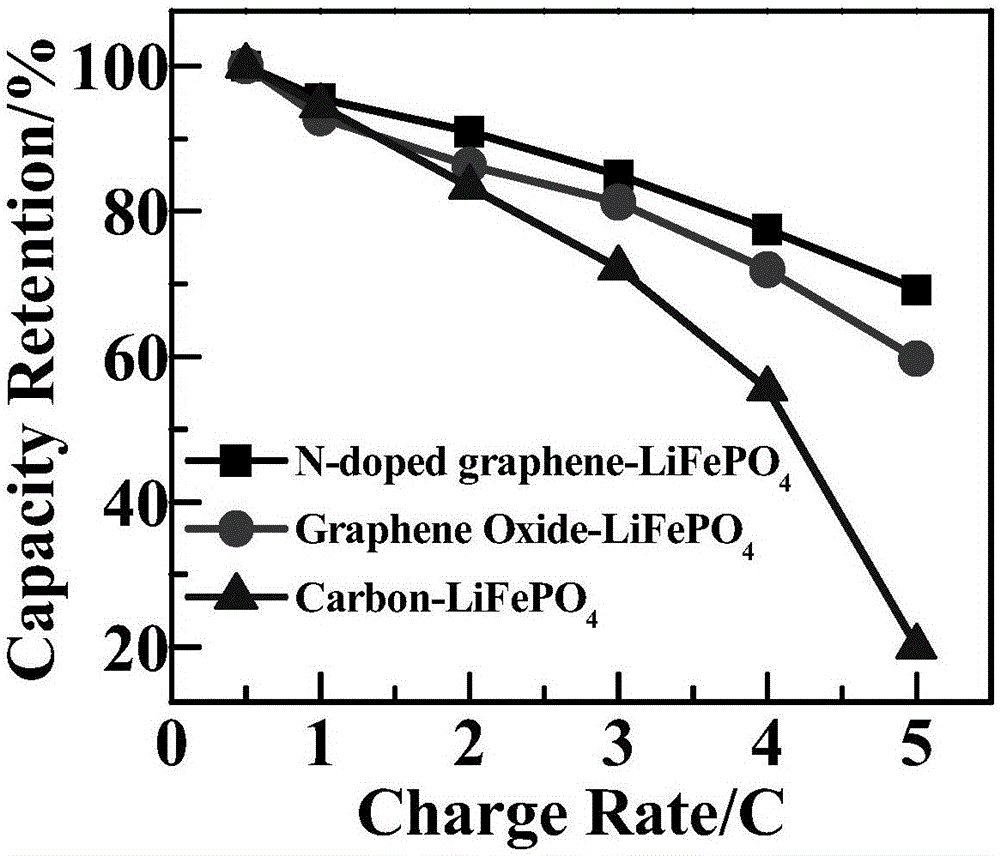

A graphene-coated, lithium iron phosphate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor coating uniformity and low electrical performance, and achieve good electrical performance, good rate performance, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

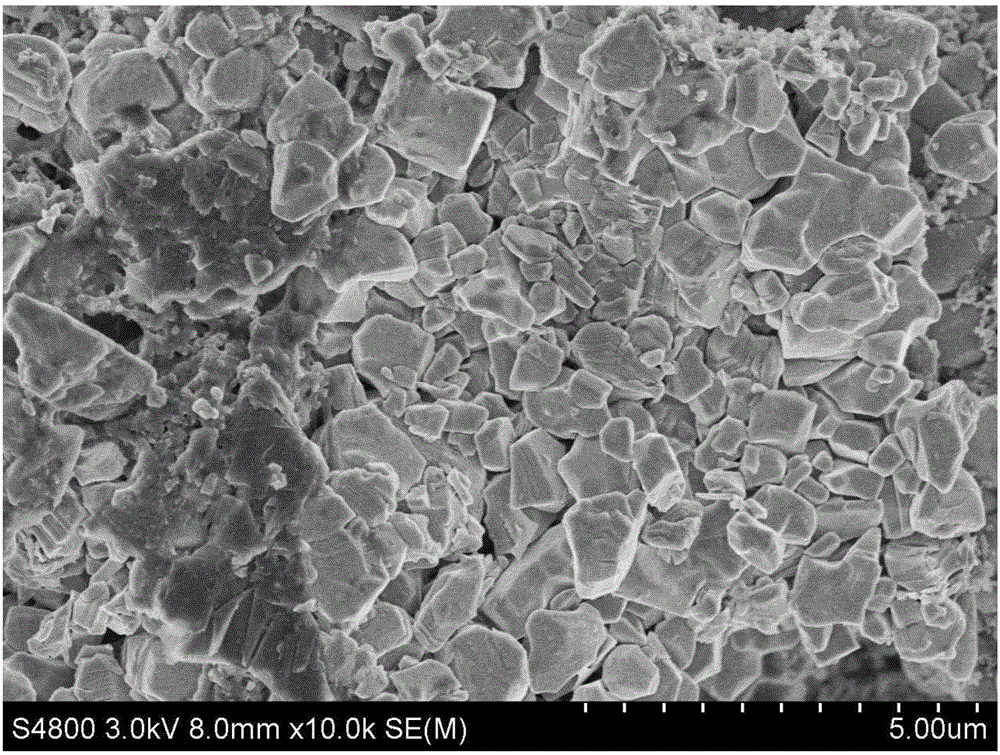

Embodiment 1

[0037] The preparation method of the nitrogen-doped graphene-coated lithium iron phosphate cathode material in this embodiment comprises the following steps:

[0038] S1. Take 33 mL of 5 mg / mL graphene oxide aqueous solution, dilute with water to 100 mL, ultrasonically disperse for 10 min, then add 15 g of urea and sonicate for 30 min to obtain graphene oxide-urea mixture A;

[0039] S2. Add 0.012 mol of lithium nitrate, 0.024 mol of ammonium dihydrogen phosphate, and 0.024 mol of ferric nitrate into 80 mL, 30 ml, and 60 ml of deionized water, respectively, and mix to obtain lithium nitrate dispersion, ammonium dihydrogen phosphate dispersion, and ferric nitrate dispersion , and then lithium nitrate dispersion, ammonium dihydrogen phosphate dispersion and ferric nitrate dispersion were sequentially and slowly added to mixture A, each addition was stirred at a speed of 50r / min for 0.5h to obtain mixture B;

[0040] S3, drying the mixture B at 80° C. for 24 hours to prepare a ni...

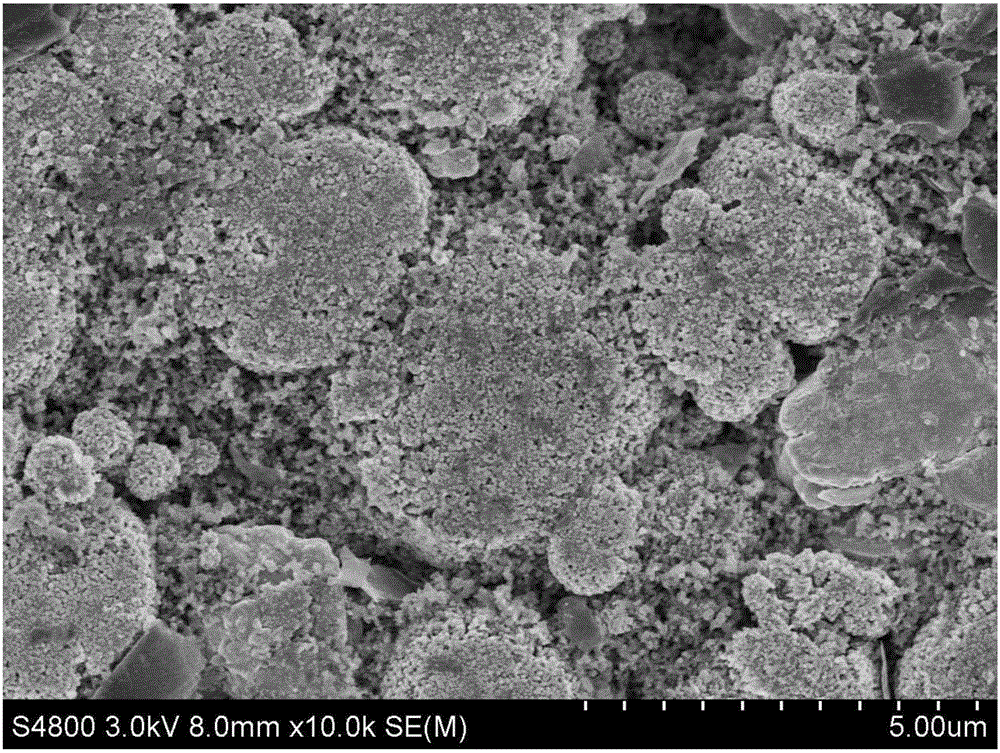

Embodiment 2

[0052] The preparation method of the nitrogen-doped graphene-coated lithium iron phosphate cathode material in this embodiment comprises the following steps:

[0053] S1. Take 50 mL of 3 mg / mL graphene oxide aqueous solution, dilute with water to 100 mL, ultrasonically disperse and disperse for 10 min, then add 15 g of urea and sonicate for 30 min to obtain graphene oxide-urea mixture A;

[0054] S2. Add 0.012 mol of lithium carbonate, 0.024 mol of ammonium dihydrogen phosphate, and 0.024 mol of ferric chloride into 80 mL, 30 ml, and 60 ml of deionized water respectively to prepare lithium carbonate dispersion, ammonium dihydrogen phosphate dispersion, and ferric chloride Dispersion liquid, and then lithium carbonate dispersion liquid, ammonium dihydrogen phosphate dispersion liquid and ferric chloride dispersion liquid were sequentially and slowly added to mixture A, each addition was stirred at a speed of 15r / min for 0.4h to obtain mixture B;

[0055] S3, drying the mixture ...

Embodiment 3

[0058] The preparation method of the nitrogen-doped graphene-coated lithium iron phosphate cathode material in this embodiment comprises the following steps:

[0059] S1. Take 16 mL of 10 mg / mL graphene oxide aqueous solution, dilute with water to 100 mL, ultrasonically disperse and disperse for 10 minutes, then add 15 g of urea and sonicate for 30 minutes to obtain graphene oxide-urea mixture A;

[0060] S2. Add 0.012 mol of lithium sulfate, 0.024 mol of ammonium dihydrogen phosphate, and 0.024 mol of ferric nitrate into 80 mL, 30 ml, and 60 ml of deionized water respectively to prepare lithium sulfate dispersion, ammonium dihydrogen phosphate dispersion and ferric nitrate dispersion , and then lithium sulfate dispersion, ammonium dihydrogen phosphate dispersion and ferric nitrate dispersion were sequentially and slowly added to the mixture A, and each addition was stirred at a speed of 350r / min for 4h to obtain the mixture B;

[0061] S3, drying the mixture B at 90° C. for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com