Method for preparing calcium silicon phosphor biological ceramic coating through two steps and application

A bioceramic and coating technology, applied in the field of materials, can solve the problems of implantation failure, poor electrolyte stability, low biological activity, etc., and achieve the effect of good biological properties and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this experiment, a self-made magnesium-zinc-calcium alloy was selected as the micro-arc oxidation matrix, and the main components of the matrix (%, mass fraction), as shown in Table 1 (Bal: is the balance):

[0070] Table 1

[0071]

[0072] The sample was cut into small pieces of 10×10×8mm, polished on 400#, 600# and 1200# sandpaper before the experiment, and then rinsed with alcohol and deionized water. The electrolyte composition of the test is 7.5g / L Na 2 SiO 3 9H 2 O, 0.125mol / L KOH, 0.087mol / L NH 4 HF 2 , 10ml / L glycerin. The equipment used is the WHD-30 micro-arc oxidation equipment of Harbin Institute of Technology. The micro-arc oxidation adopts constant voltage mode, using a forward voltage of 400V, a frequency of 600Hz, a positive duty cycle of 40%, a negative duty cycle of 30%, a ratio of positive and negative pulses of 1:1, and a power-on reaction of 7.5 minutes; the experiment During the process, the temperature is controlled at 10-30°C.

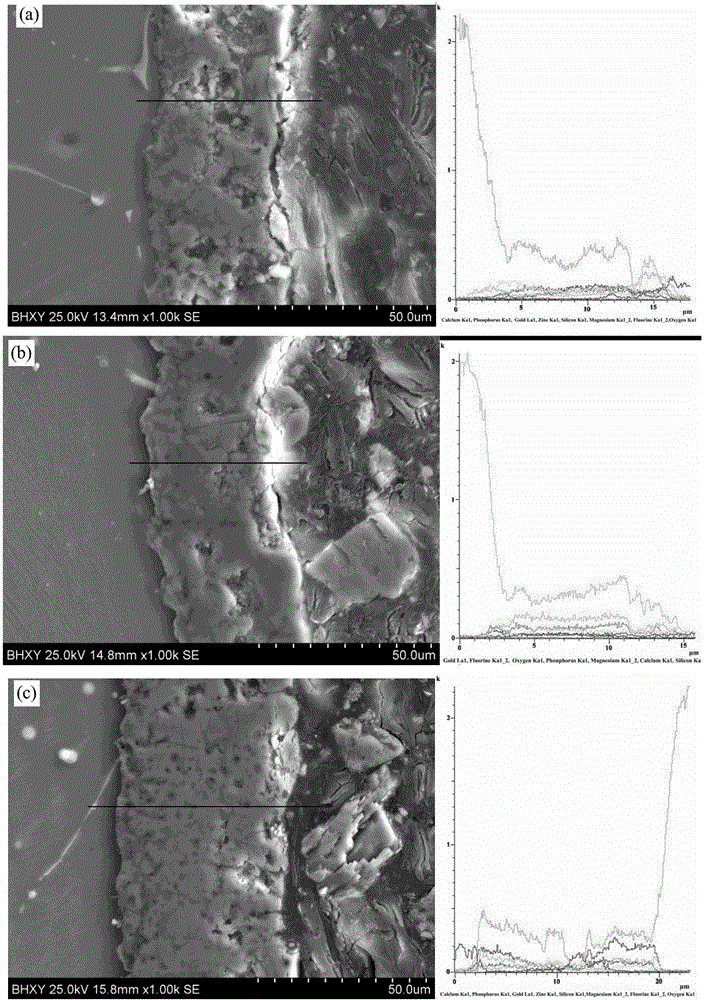

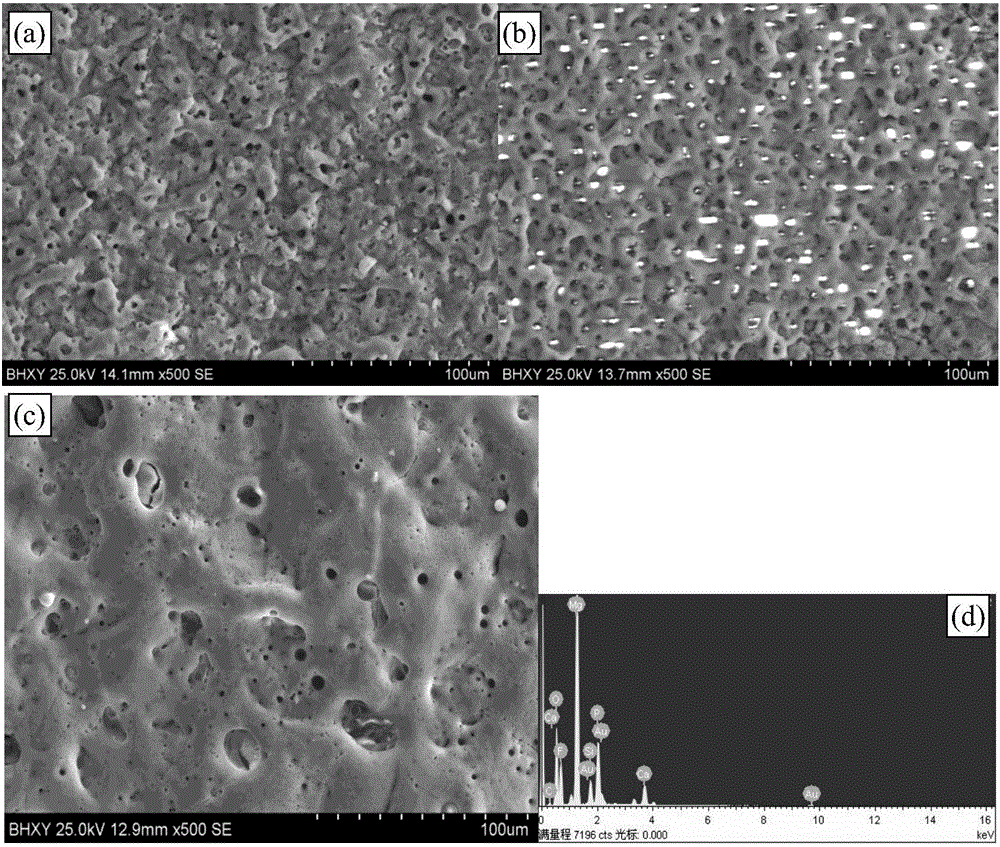

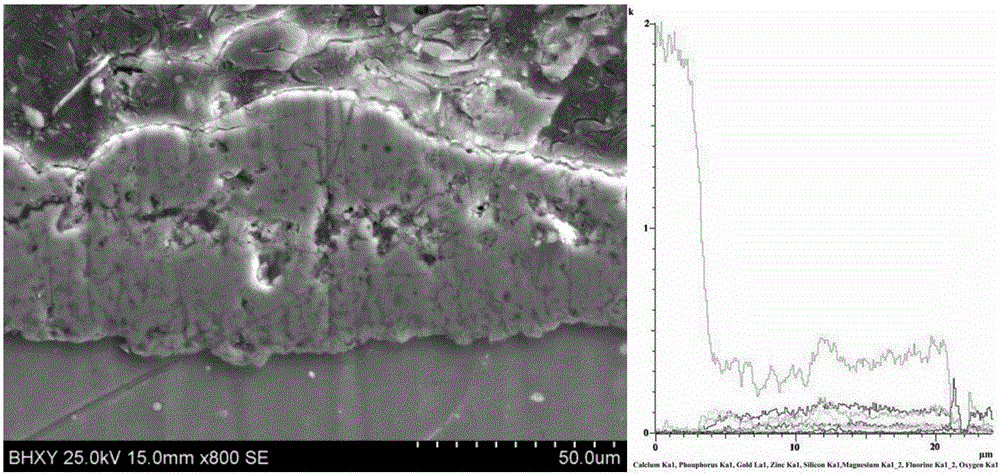

[0...

Embodiment 2

[0083] Different power frequency experiment plan

[0084] In this experiment, a self-made magnesium-zinc-calcium alloy was selected as the micro-arc oxidation matrix. The main components of the matrix are shown in Table 2 (% is the mass percentage, Bal.: is the balance):

[0085] Table 2

[0086]

[0087] The sample was cut into small pieces of 10×10×8mm, polished on 400#, 600# and 1200# sandpaper before the experiment, and then rinsed with alcohol and deionized water. The electrolyte composition of the test is 12.5g / L Na 2 SiO 3 9H 2 O, 0.125mol / L KOH, 0.087mol / L NH 4 HF 2 , 10ml / L glycerin. The equipment used is the WHD-30 micro-arc oxidation equipment of Harbin Institute of Technology. The micro-arc oxidation adopts constant voltage mode, using a forward voltage of 400V, a frequency of 600Hz, a positive duty cycle of 40%, a negative duty cycle of 30%, a ratio of positive and negative pulses of 1:1, and a power-on reaction of 7.5 minutes; the experiment During the...

Embodiment 3

[0100] Negative Voltage Experiment Protocol

[0101] In this experiment, self-made magnesium, zinc and calcium were selected as the micro-arc oxidation matrix, and the main components of the matrix are shown in Table 4 (% is mass percentage, Bal.: is the balance):

[0102] Table 4

[0103]

[0104] The sample was cut into small pieces of 10×10×8mm, polished on 400#, 600# and 1200# sandpaper before the experiment, and then rinsed with alcohol and deionized water. The electrolyte composition of the test is 12.5g / L Na 2 SiO 3 9H 2 O, 0.125mol / L KOH, 0.087mol / L NH 4 HF 2 and 10ml / L glycerin. The equipment used is the WHD-30 micro-arc oxidation equipment of Harbin Institute of Technology. The micro-arc oxidation adopts constant voltage mode, using a forward voltage of 400V, a frequency of 600Hz, a positive duty cycle of 40%, a negative duty cycle of 30%, a ratio of positive and negative pulses of 1:1, and a power-on reaction of 7.5 minutes; the experiment During the proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com