Catalyst for preparing 1,4-butanediol as well as preparation method and application thereof

A catalyst, butanediol technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Effect of reduced separation process, excellent hydrogenation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

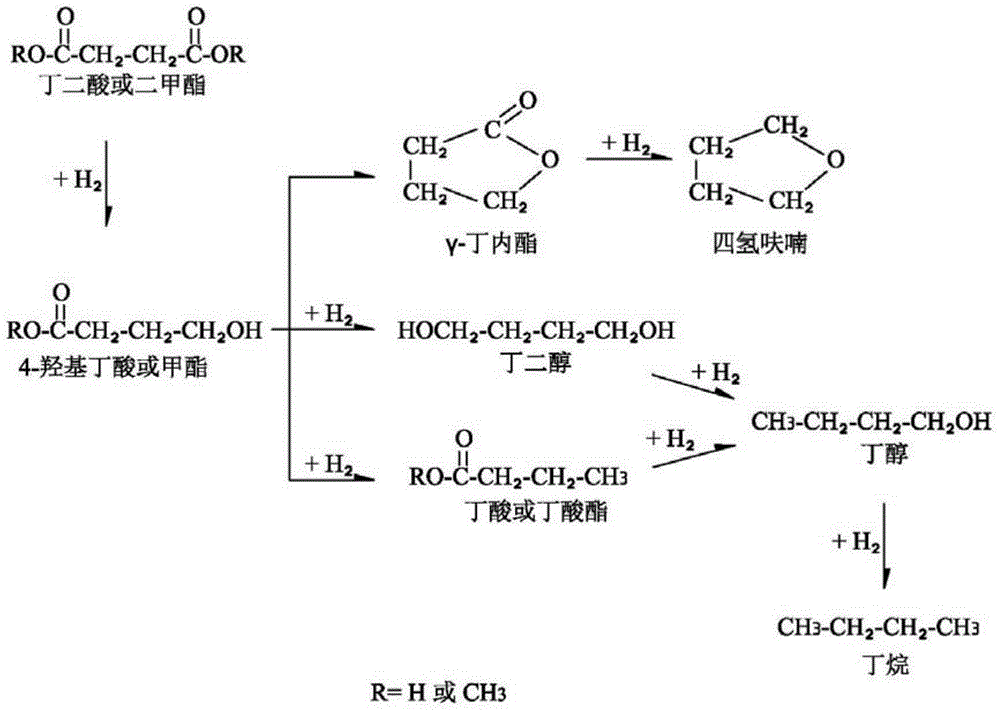

Problems solved by technology

Method used

Image

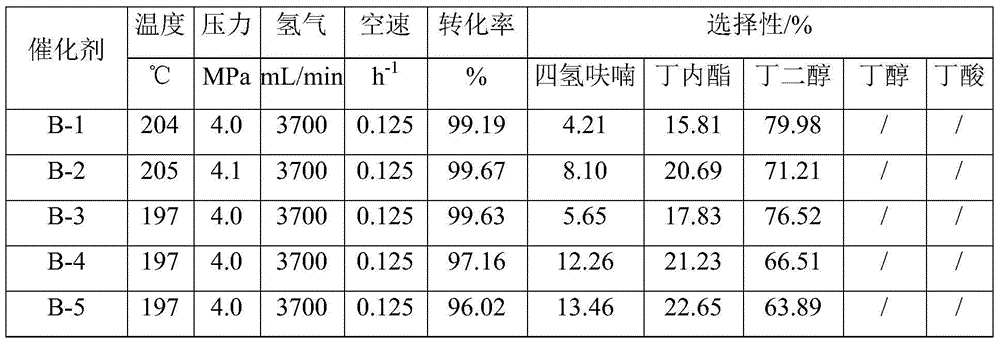

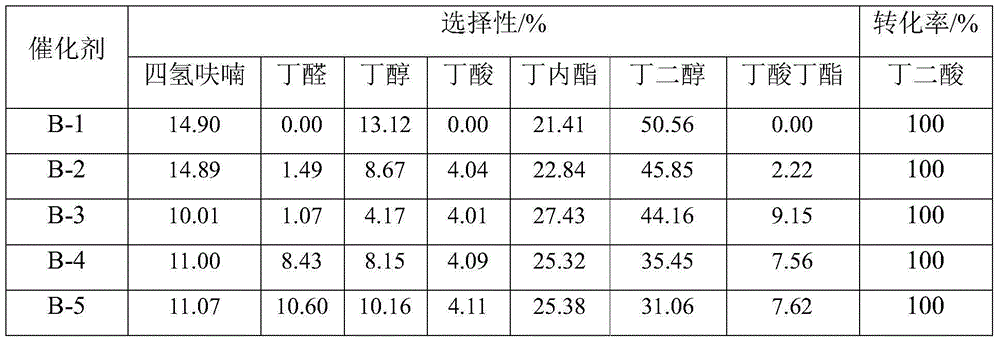

Examples

preparation example Construction

[0030]In the present invention, the catalyst for preparing butanediol can be prepared by various methods for preparing catalysts conventionally used in the art. The catalyst preparation method of the present invention can be obtained by existing catalyst preparation techniques, such as impregnation method, ion exchange method, blending method, kneading method, co-precipitation, deposition-precipitation, steamed ammonium precipitation, melting-suction filtration, ball milling and sol-gel methods. More preferred methods include coprecipitation, deposition-precipitation, distilled ammonium precipitation, melting-suction filtration, ball milling and a combination of sol-gel, these preparation catalyst methods are well known to those skilled in the art, in There are detailed introductions in books in this field, such as "Design and Development of Industrial Catalysts" written by Huang Zhongtao, and "Preparation of Solid Catalysts" written by Professor Gerhard Ertl. Wherein, the br...

preparation example 1

[0060] This preparation example is used to illustrate the catalyst for preparing butanediol and the preparation method thereof of the present invention.

[0061] Take 1L of 1.0mol / L copper nitrate aqueous solution in a beaker, add 1L of 1.0mol / L zinc nitrate, add 0.5L of 1mol / L tin tetrachloride aqueous solution to it dropwise under the condition of full stirring, and then add Guangzhou Precipitated silica 15g (silicon dioxide (SiO 2 ) content ≥ 95.0% by weight, fineness (325 mesh sieve residue) ≤ 1.8%, specific surface area of 400-600m 2 / g), and then slowly drip 1mol / L aqueous sodium carbonate solution to pH 7.0 to obtain a precipitate, which is washed and filtered, and dried overnight to obtain a dry filter cake. Granulating, roasting and decomposing, and tableting to obtain catalyst B-1.

[0062] Tested by a wavelength dispersive X-ray fluorescence spectrometer, the catalyst B-1 contains 30% by weight of tin as oxide, 31% by weight of copper as oxide, 33% by weight of ...

preparation example 2

[0064] This preparation example is used to illustrate the catalyst for preparing butanediol and the preparation method thereof of the present invention.

[0065] Take 1.2 L of 1.0 mol / L copper nitrate aqueous solution and place it in a beaker, add 0.8 L of 1.0 mol / L zinc nitrate, and add dropwise 0.4 L of 1 mol / L tin tetrachloride aqueous solution to it under the condition of sufficient stirring, Then add the precipitated silica 20g (silicon dioxide (SiO2) produced by Guangzhou People's Chemical Factory 2 ) content ≥ 95.0% by weight, fineness (325 mesh sieve residue) ≤ 1.8%, specific surface area of 400-600m 2 / g), and then slowly drip 1mol / L aqueous sodium carbonate solution to pH 7.2 to obtain a precipitate, which is washed and filtered, and dried overnight to obtain a dry filter cake. Granulating, roasting and decomposing, and tableting to obtain catalyst B-2.

[0066] Tested by a wavelength dispersive X-ray fluorescence spectrometer, the catalyst B-2 contains 25% by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com