Graphene/titanium carbide composite coating and preparation method thereof

A composite coating and graphene technology, applied in the coating, metal material coating process, etc., can solve the problems of poor wear resistance, high brittleness, insufficient bonding force with the substrate, etc., achieve excellent mechanical properties and improve anti-wear properties , Improve the effect of intrinsic brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

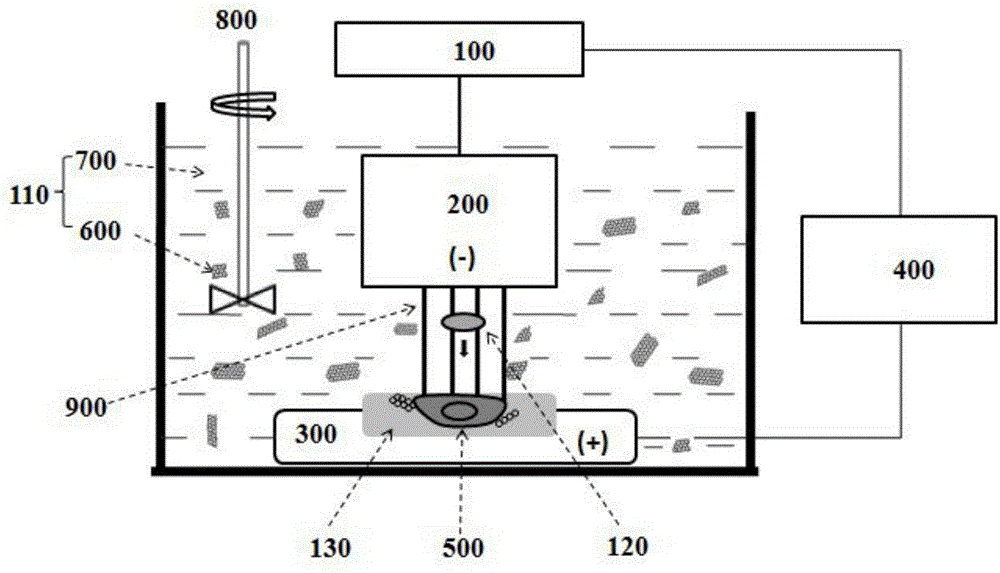

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 tool electrode

[0033] Titanium carbide with a particle size of 0.2-2 μm and zinc stearate (mass ratio 99:1) are uniformly mixed by ball milling, and the resulting mixture is pressed into a stainless steel mold with a molding pressure of 15 MPa. Under the protection of the atmosphere, sinter at 700°C for 1 hour, and then obtain a titanium carbide semi-sintered body used as a tool electrode after cooling in the furnace.

Embodiment 2

[0035] The difference from Example 1 lies in that the molding pressure is 5 MPa, the sintering temperature is 1000° C., and the sintering time is 3 hours.

Embodiment 3

[0036] The preparation of embodiment 3 graphene / kerosene solid-liquid mixed processing fluid

[0037] The graphene / kerosene solid-liquid mixed processing fluid is composed of graphene 600 and kerosene 700 solid-liquid two-phase. Graphene is modified by alkyl functionalization before mixing with kerosene. In this example, an alkyl functional group with a carbon chain length of C12-C18 is grafted on the surface of graphene through the two-step method of acylation activation and amide reaction.

[0038] The steps of graphene alkyl functional modification are as follows: take 1 g of graphene containing -COOH functional groups on the surface and disperse it in 1 L of a mixture of dimethylformamide and thionyl chloride (volume ratio 1:1), and react at 70°C After 24 hours, it was filtered and vacuum-dried at 100°C to obtain acylated activated graphene. The acylated activated graphene was dispersed in 1L dodecylamine liquid, reacted at 120°C for 4 days, filtered and dried in vacuum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap