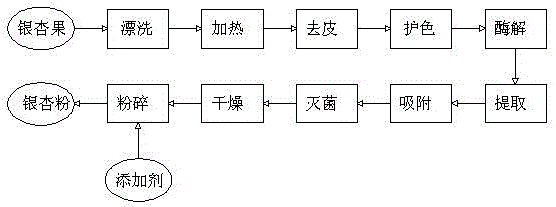

Method for preparing gingko powder

A technology of ginkgo powder and ginkgo, which is applied in the preparation of ginkgo products and the processing field of ginkgo powder, can solve the problems of long fermentation time, large amount of resin consumption, and large loss of active substances, etc., achieve rich nutrients, improve extraction efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1. Preparation of amygdalinase: Grind 100g of bitter almonds, soak in 200ml of ethanol for 12h, filter with suction, and dry the filter cake in vacuum at 40°C for 4h. Take it out and add 500ml of ammonia water for Soxhlet extraction for 2 hours, add dilute acetic acid to the filtrate for neutralization, suction filtration, add 20ml of ethanol to the filtrate, refrigerate for 12 hours, suction filtration, and dry at low temperature to obtain amygdalinase.

[0032] 2. The compound enzyme is a mixed enzyme of cellulase, pectinase, amylase and protease, purchased from the National Institute of Inspection and Quarantine with product numbers of 109262, 116864, 120987, 123425 respectively. The cellulase, pectinase, amylase and The protease is mixed according to the weight ratio of 2:2:1:1 to obtain the compound enzyme.

[0033] 3. Mix the newly prepared amygdalinase and compound enzyme at a weight ratio of 9:1 to obtain the enzyme used for enzymolysis.

[0034] 4. The detecti...

Embodiment 1

[0036] The preparation process of the ginkgo powder of the present embodiment is as follows:

[0037] 1) Rinse: take Taizhou ginkgo fruit in October, remove the outer shell, and wash;

[0038] 2) Heating: Heating until the inner shell cracks; the heating temperature is 80°C, the heating method is steam heating, and the heating time is 2 hours;

[0039] 3) Peeling: Pour it into the ginkgo peeling machine to break the shell and inner skin, blow off the inner skin with a fan, take out the kernels, remove the kernel core, and wash;

[0040] 4) Color protection: crush and weigh 1Kg ginkgo powder, soak in 0.05% w / v citric acid aqueous solution at room temperature for 2 hours at 30°C, filter out to obtain ginkgo powder;

[0041] 5) Enzymolysis: Add 50Kg water, 5Kg ethyl acetate, 5g Tween 20 and 5g enzyme to hydrolyze at 40°C for 6 hours;

[0042] 6) Extraction: 2450MHz microwave extraction for 1h, saturated aqueous sodium hydroxide solution to absorb acid gas;

[0043] 7) Adsorpti...

Embodiment 2

[0049] The preparation process of the ginkgo powder of the present embodiment is as follows:

[0050] 1) Rinse: take Taixing ginkgo fruit in October, remove the outer shell, and wash;

[0051] 2) Heating: Heating until the inner shell cracks; the heating temperature is 100°C, the heating method is microwave heating, and the heating time is 0.1h;

[0052] 3) Peeling: Pour it into the ginkgo peeling machine to break the shell and inner skin, blow off the inner skin with a fan, take out the kernels, remove the kernel core, and wash;

[0053] 4) Color protection: pulverize and weigh 1Kg ginkgo powder, soak in 0.01% w / v citric acid aqueous solution for 0.1h, soaking temperature is 20°C, filter out to obtain ginkgo powder;

[0054] 5) Enzymolysis: Add 50Kg water, 2Kg ethyl formate, 1g Tween 80 and 1g enzyme to hydrolyze at 30°C for 12 hours;

[0055] 6) Extraction: 2450MHz microwave extraction for 2 hours, saturated aqueous sodium hydroxide solution to absorb acid gas;

[0056] 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com