Foliage fertilizer for planting grapes and manufacturing method of foliage fertilizer

A production method and foliar fertilizer technology are applied in the preparation of organic fertilizers, nitrogen fertilizers, potash fertilizers, etc., which can solve the problems of slow root absorption of plants, affecting yield, and lack of soil nutrient elements, and achieve accelerated speed and nutrient transformation. Improve the absorption efficiency and promote the growth of branches and buds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

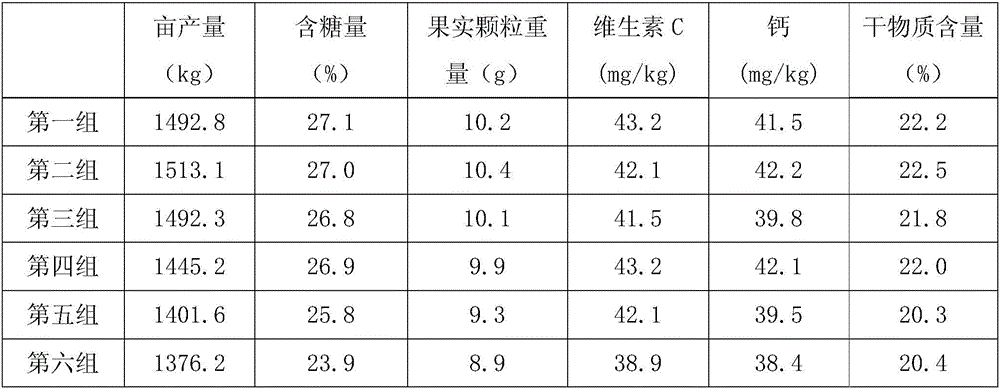

Image

Examples

Embodiment 1

[0025] (1) Preparation of raw materials

[0026] Corrosion agent: The following raw materials are mixed with iron oxide, magnesium phosphate, ammonium chloride, calcium cyanamide, potassium fluoride, and humic acid in a mass ratio of 4:1:2:3:1:3.

[0027] Foliar fertilizer raw materials: select the raw materials according to the following weight ratio: 20 parts of vine, 15 parts of shell powder, 25 parts of plant ash, 10 parts of animal bone meal, 15 parts of brown sugar, 10 parts of human excrement, 10 parts of soybean meal, 10 parts of excess Calcium phosphate, 10 parts boric acid, 10 parts potassium dihydrogen phosphate, 3 parts ammonium nitrate, 5 parts magnesium sulfate, 1 part manganese sulfate, 0.006 parts corrosion inhibitor, 100 parts water.

[0028] (2) Preparation method of foliar fertilizer

[0029] (1) Select raw materials according to the above weight parts;

[0030] (2) Put the grape vines in a pulverizer and smash them through a 20-mesh sieve; add the grape vine powder ...

Embodiment 2

[0033] (1) Preparation of raw materials

[0034] Corrosion agent: The following raw materials are mixed with iron oxide, magnesium phosphate, ammonium chloride, calcium cyanamide, potassium fluoride, and humic acid in a mass ratio of 4:1:2:3:1:3.

[0035] Foliar fertilizer raw materials: select the raw materials according to the following weight ratio: 25 parts of vine, 20 parts of shell powder, 30 parts of plant ash, 15 parts of animal bone meal, 20 parts of brown sugar, 12 parts of human excrement, 12 parts of soybean meal, 15 parts of excess Calcium phosphate, 15 parts of boric acid, 15 parts of potassium dihydrogen phosphate, 5 parts of ammonium nitrate, 8 parts of magnesium sulfate, 3 parts of manganese sulfate, 0.01 parts of corrosion inhibitor, 120 parts of water.

[0036] (2) Preparation method of foliar fertilizer

[0037] (1) Select raw materials according to the above weight parts;

[0038] (2) Put the grape vines into a pulverizer and smash through a 40-mesh sieve; add the ...

Embodiment 3

[0041] (1) Preparation of raw materials

[0042] Corrosion agent: The following raw materials are mixed with iron oxide, magnesium phosphate, ammonium chloride, calcium cyanamide, potassium fluoride, and humic acid in a mass ratio of 4:1:2:3:1:3.

[0043] Foliar fertilizer raw materials: select the raw materials according to the following weight ratio: 21 parts of vine, 17 parts of shell powder, 26 parts of plant ash, 14 parts of animal bone meal, 18 parts of brown sugar, 11 parts of human excrement, 10 parts of soybean meal, 11 parts of excess Calcium phosphate, 14 parts boric acid, 13 parts potassium dihydrogen phosphate, 4 parts ammonium nitrate, 6 parts magnesium sulfate, 2 parts manganese sulfate, 0.009 parts corrosion inhibitor, 105 parts water.

[0044] (2) Preparation method of foliar fertilizer

[0045] (1) Select raw materials according to the above weight parts;

[0046] (2) Put the grape vines in a pulverizer and smash them through a 20-mesh sieve; add the grape vine powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com