Nanometer/micrometer composite graphical sapphire substrate and preparation method thereof

A sapphire substrate and composite patterning technology, which is applied in chemical instruments and methods, separation methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of low light extraction efficiency of GaN-based LEDs, and increase internal quantum efficiency and light extraction efficiency , Improve crystal quality, change the effect of propagation direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

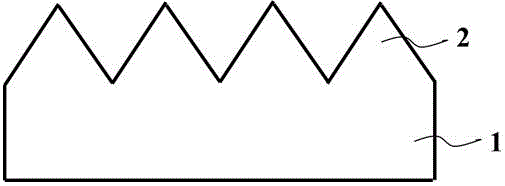

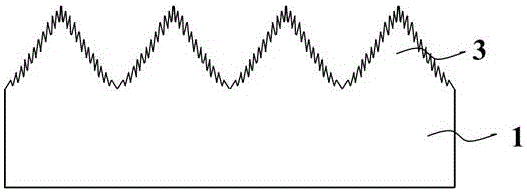

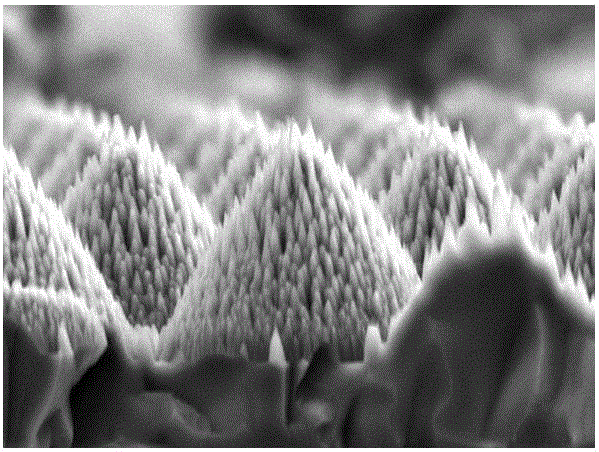

[0035] (1) Preparing micron-scale patterns 2 on the sapphire substrate 1;

[0036] The existing conventional photolithography and ICP dry etching processes are adopted. First spin coat a layer of photoresist on the flat sapphire substrate, the thickness of the photoresist is 3 μm; use a photolithography machine to expose and develop to obtain a mask pattern; use the photoresist as a mask. The sapphire substrate is etched with an ICP device to obtain a sapphire substrate 1 with micron-scale patterns 2 . Micron-scale figure 2 is a cone with a height of 1 μm and a base radius of 2 μm.

[0037] (2) Cleaning the substrate, and then using a magnetron sputtering system to deposit a nickel film with a thickness of 10nm on the micron-scale pattern 2;

[0038] (3) Put the substrate on which the nickel film was deposited in step (2) into a rapid annealing furnace, and anneal in a nitrogen atmosphere at an annealing temperature of 850°C for 180 seconds, so that the nickel film is agglomer...

Embodiment 2

[0047] (1) Preparing micron-scale patterns 2 on the sapphire substrate 1;

[0048] The existing conventional photolithography and ICP dry etching processes are adopted. First spin coat a layer of photoresist on the flat sapphire substrate, the thickness of the photoresist is 3 μm; use a photolithography machine to expose and develop to obtain a mask pattern; use the photoresist as a mask. The sapphire substrate is etched with an ICP device to obtain a sapphire substrate 1 with micron-scale patterns 2 . The micron-scale pattern 2 is a truncated cone with a height of 3 μm and a base radius of 6 μm.

[0049] (2) Cleaning the substrate, and then using a magnetron sputtering system to deposit a nickel film with a thickness of 20nm on the micron-scale pattern 2;

[0050] (3) Put the substrate on which the nickel film was deposited in step (2) into a rapid annealing furnace, and anneal in a nitrogen atmosphere at an annealing temperature of 850°C for 180 seconds, so that the nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com