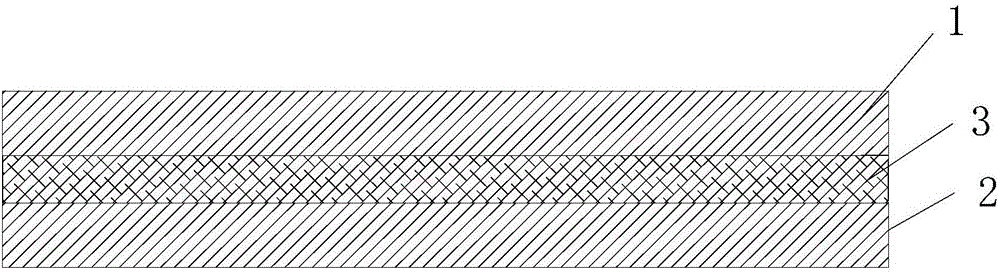

Lithium ion battery nanofiber graphene composite membrane and preparation method thereof

A graphene composite, lithium-ion battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low tensile strength of lithium-ion nanofiber separators, and achieve good wettability, high porosity, and high specific gravity. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of nanofiber graphene composite diaphragm for lithium ion battery, comprising the following steps:

[0040] 1) The manufacturing process of the PVDF-based polymer nanofiber layer is:

[0041] 1.1) The mass ratio of the three component polymers is: PVDF65-85 parts, PVDF-HFD 10-25 parts, PAN 5-10 parts; the three component polymers are mixed according to the mass part ratio, and after stirring , to achieve good uniformity;

[0042] 1.2) The mass-number ratio of the three component solvents is: 15-30 parts of N.N dimethylformamide, 65-80 parts of dimethylacetamide, and 5-30 parts of acetone; Mix together and stir to form a transparent solution;

[0043] 1.3) Add the melted solvent into the three-component polymer mixture, after stirring, let it stand for 4-6 hours, then stir with a magnetic stirrer, first at a low speed of 0.5 hours, then at a medium speed of 5-6 hours , to stop between the viscosity of 600-750Pa.s;.

[0044] 1.4) Leave the configu...

Embodiment 1

[0055] In this embodiment, the proportions of the mass content of the upper layer, the middle layer and the lower layer to the total mass are respectively: the upper layer and the lower layer each account for 15%, and the middle layer accounts for 70%.

[0056] In the PVDF-based polymer nanofiber layer, the three-component polymer mass fraction ratio is: 65 parts of PVDF, 10 parts of PVDF-HFD, and 5 parts of PAN; the mass fraction ratio of the three component solvents is: N.N dimethyl 15 parts of methyl formamide, 65 parts of dimethylacetamide, and 5 parts of acetone.

[0057] Described PVDF-based graphene nanofiber layer comprises graphite powder, inorganic strong protonic acid (concentrated sulfuric acid, fuming nitric acid or mixture), potassium permanganate and sodium nitrate mixture, hydrogen peroxide, coupling agent titanate, hydrazine hydrate, Sodium polystyrene sulfonate (PSS), the mass ratio of 7 components is: graphite powder 40 parts, inorganic acid protonic acid (c...

Embodiment 2

[0060] In this embodiment, the mass content of the upper layer and the lower layer accounts for 16% of the total mass, and the mass content of the middle layer accounts for 68% of the total mass.

[0061] In the PVDF-based polymer nanofiber layer, the mass fraction ratio of the three component polymers is: 67 parts of PVDF, 11.5 parts of PVDF-HFP, and 5.5 parts of PAN; the mass fraction ratio of the three component solvents is: N.N - 17 parts of dimethylamide, 67 parts of dimethylacetamide, 8 parts of acetone.

[0062] Described PVDF-based graphene nanofiber layer comprises graphite powder, inorganic strong protonic acid (concentrated sulfuric acid, fuming nitric acid or mixture), potassium permanganate and sodium nitrate mixture, hydrogen peroxide, coupling agent titanate, hydrazine hydrate, Sodium polystyrene sulfonate (PSS), the mass ratio of 7 components is: graphite powder 42 parts, inorganic acid protonic acid (concentrated sulfuric acid, fuming nitric acid or mixture) 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com