Organic silicon resin aluminum-based copper-clad plate and production method thereof

A technology of aluminum-based copper-clad laminates and organic silicon, which is applied in the direction of circuit substrate materials, chemical instruments and methods, and synthetic resin layered products, can solve the problem of large thermal resistance of glass fiber cloth, poor heat dissipation, and brittleness of the insulating layer of glass fiber cloth. problems, to achieve the effect of mild reaction conditions, high thermal conductivity, and superior electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

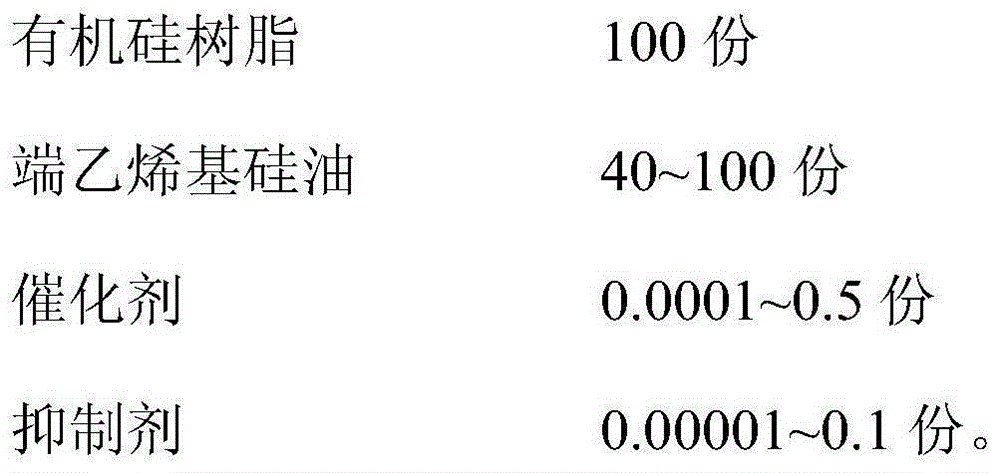

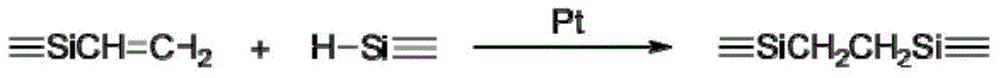

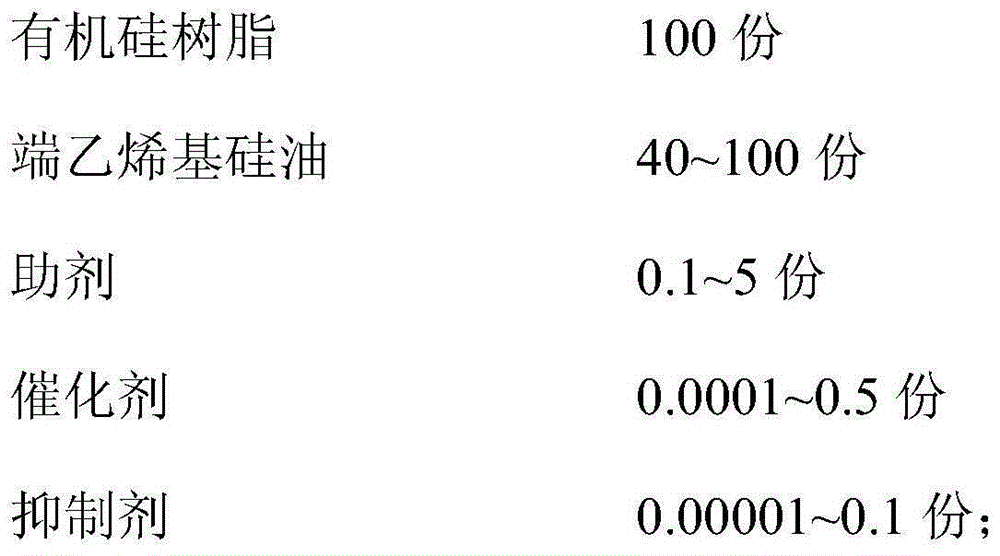

Method used

Image

Examples

Embodiment 1

[0049] Design formula according to Si-H (silicon hydrogen) / Si-Vi (silicon vinyl)=1.6 (molar ratio), weigh 100 parts of methylphenyl vinyl silicone resin (vinyl mass fraction is 1.0%), dissolve in In 50 parts of methylphenyl-terminated vinyl silicone oil with a viscosity of 250mPa.s, dissolve evenly and add 4.56 parts of methylphenyl hydrogen-containing silicone oil (the hydrogen content is 1.3%) and 0.1 part of γ-glycidyl ether oxypropyl Trimethoxysilane (manufactured by Dow Corning in the United States), after stirring at a high speed, weigh 0.001 part of hexynol, add 0.01 part of platinum-methylphenylvinyl complex after stirring for 30 minutes, and add 150 parts of 3.5 Boron nitride with a particle size of μm was stirred at room temperature for 1 hour and emulsified for 20 minutes to obtain a silicone resin composition.

[0050] Use a piece of 35μm clean copper foil to coat the above-mentioned silicone resin composition with a layer of 100μm adhesive layer with an automatic ...

Embodiment 2

[0052] Design formula according to Si-H / Si-Vi=1.4 (molar ratio), weigh 100 parts of methyl vinyl silicone resin (vinyl mass fraction is 3.5%), dissolve into 70 parts of methyl terminal with a viscosity of 3000mPa.s In vinyl silicone oil, after dissolving evenly, add 18.15 parts of methyl hydrogen-containing silicone oil (hydrogen mass fraction is 1.0%) and 1.8 parts of W-903 dispersant (manufactured by BYK Company in Germany), and weigh 0.00005 parts of hexyl Alkynyl alcohol, after stirring for 30 minutes, add 0.005 parts of platinum-methyl vinyl complex, continue stirring for 30 minutes, add 38 parts of silicon carbide with a particle size of 35 μm, 300 parts of 3.5 μm alumina and 40 parts of rutile titanium dioxide, and stir at room temperature for 1 hour. Emulsified for 20 minutes to obtain a silicone resin composition.

[0053] An aluminum-based copper-clad laminate was obtained in the same manner as in Example 1 except that the resin composition was used.

Embodiment 3

[0055] Design formula according to Si-H / Si-Vi=1.1 (molar ratio), weigh 100 parts of methyl vinyl silicone resin (vinyl mass fraction is 5.5%), dissolve into 100 parts of methyl terminal with a viscosity of 9500mPa.s In vinyl silicone oil, after dissolving evenly, add 28.0 parts of methyl hydrogen-containing silicone oil (hydrogen mass fraction is 0.8%) and 4.5 parts of γ-glycidyl etheroxypropyl trimethoxysilane (manufactured by Dow Corning in the United States), and stir evenly at high speed Finally, weigh 0.1 part of tetramethyltetravinylcyclotetrasiloxane (D4vi), add 0.0001 part of platinum-methylvinyl complex after stirring for 30 minutes, and add 55 parts of alumina with a particle size of 3.5 μm after stirring for 30 minutes. and 155 parts of aluminum nitride, stirred at room temperature for 1 hour, and emulsified for 20 minutes to obtain a silicone resin composition.

[0056] An aluminum-based copper-clad laminate was obtained in the same manner as in Example 1 except th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com