Preparation method of antibacterial cellulose flat nanofiltration membrane

A cellulose and nanofiltration membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of nanofiltration membranes that are difficult to biodegrade petrochemical products, little research, human economy, environment and resource burden, etc. Achieve the effects of high water flux, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

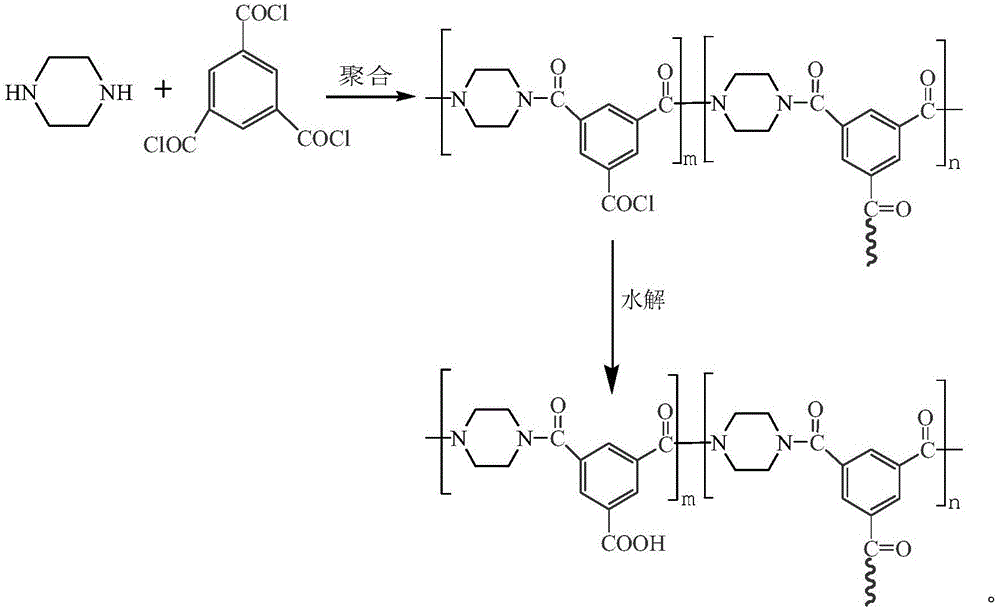

Image

Examples

preparation example Construction

[0022] A kind of preparation method of antibacterial cellulose flat nanofiltration membrane of the present invention, this preparation method comprises following specific operation steps:

[0023] (1), preparation of cellulose casting solution: under the condition of 80°C-110°C, configure N-methylmorpholine-N-oxide solvent with a water content of 10%-16%, and then in the N-methyl Adding n-propyl gallate and nano-SiO to the morpholine-N-oxide solvent 2 porogen, and nano-TiO 2 Antibacterial agent or nano-silver antibacterial agent, finally add cellulose pulp; then stir and dissolve, after the dissolution is complete, vacuum degassing or static degassing for 5-8 hours, then obtain a uniform and transparent cellulose casting solution;

[0024] Wherein, the addition amount of n-propyl gallate is 0.2%-0.3% of the solvent content of N-methylmorpholine-N-oxide; the addition amount of cellulose pulp is N-methylmorpholine-N-oxide 4%-8% of solvent content; nano-SiO 2 The amount of por...

Embodiment 1

[0032] Under the condition of 110°C, configure N-methylmorpholine-N-oxide solvent with a water content of 13.3%, and then add n-propyl gallate, nano SiO 2 porogen, and nano-TiO 2 Antibacterial agent, finally add cellulose pulp (wherein, the addition of n-propyl gallate is 0.25% of N-methylmorpholine-N-oxide solvent content; The addition of cellulose pulp is N-methyl 4% of morpholine-N-oxide solvent content; nano-SiO 2 The addition of porogen is 1.8% of the content of cellulose pulp; nano TiO 2 The addition of the antibacterial agent is 0.5% of the content of the cellulose pulp); then stirring and dissolving, after the dissolution is complete, vacuum degassing or static degassing for 5 hours, then obtain a uniform and transparent cellulose casting solution;

[0033] At a constant temperature of 80°C, the obtained cellulose casting solution is evenly coated on the non-woven fabric to obtain a cellulose primary film; then the obtained cellulose primary film is put into deioniz...

Embodiment 2

[0036] Under the condition of 105°C, configure N-methylmorpholine-N-oxide solvent with a water content of 10%, and then add n-propyl gallate, nano SiO 2 porogen, and nano-TiO 2Antibacterial agent, finally add cellulose pulp (wherein, the addition of n-propyl gallate is 0.3% of N-methylmorpholine-N-oxide solvent content; The addition of cellulose pulp is N-methyl 5% of morpholine-N-oxide solvent content; nano-SiO 2 The amount of porogen added is 1% of the content of cellulose pulp; nano-TiO 2 The antibacterial agent is added in an amount of 0.2% of the cellulose pulp content); followed by stirring and dissolving, after the dissolution is complete, vacuum degassing or static degassing for 7 hours, then obtain a uniform and transparent cellulose casting solution;

[0037] At a constant temperature of 90°C, the obtained cellulose casting solution is evenly coated on the non-woven fabric to obtain a cellulose primary film; then the obtained cellulose primary film is put into dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com