Method for preparing calcium carbonate-chitin composite powder by using crab shells as raw material and application of method

A composite powder, calcium carbonate technology, applied in chemical instruments and methods, prostheses, other chemical processes, etc., can solve the problems of complex operation process, achieve simple process, low equipment investment and energy consumption, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Use flotation to remove the residual meat on the shell of Chinese mitten crab, drum dry, and pulverize; then the powder is subjected to follow-up treatment in sequence;

[0032] 2) Mix 1 mass part of crab shell powder obtained by coarse crushing with 1 mass part of 10% sodium hydroxide solution, stir at 100°C for 0.5h, remove protein and fat, press filter, and wash with water until neutral;

[0033] 3) Add 1 mass part of hydrogen peroxide solution with a mass concentration of 5% to the powder, stir at 100°C for 0.5h to decolorize the powder, press filter, wash with water until the filtrate is colorless, add water and stir at high speed to obtain slurry;

[0034] 4) wet grinding in a vertical sand mill, press filtration, drum drying, and crushing to obtain calcium carbonate-chitin composite powder.

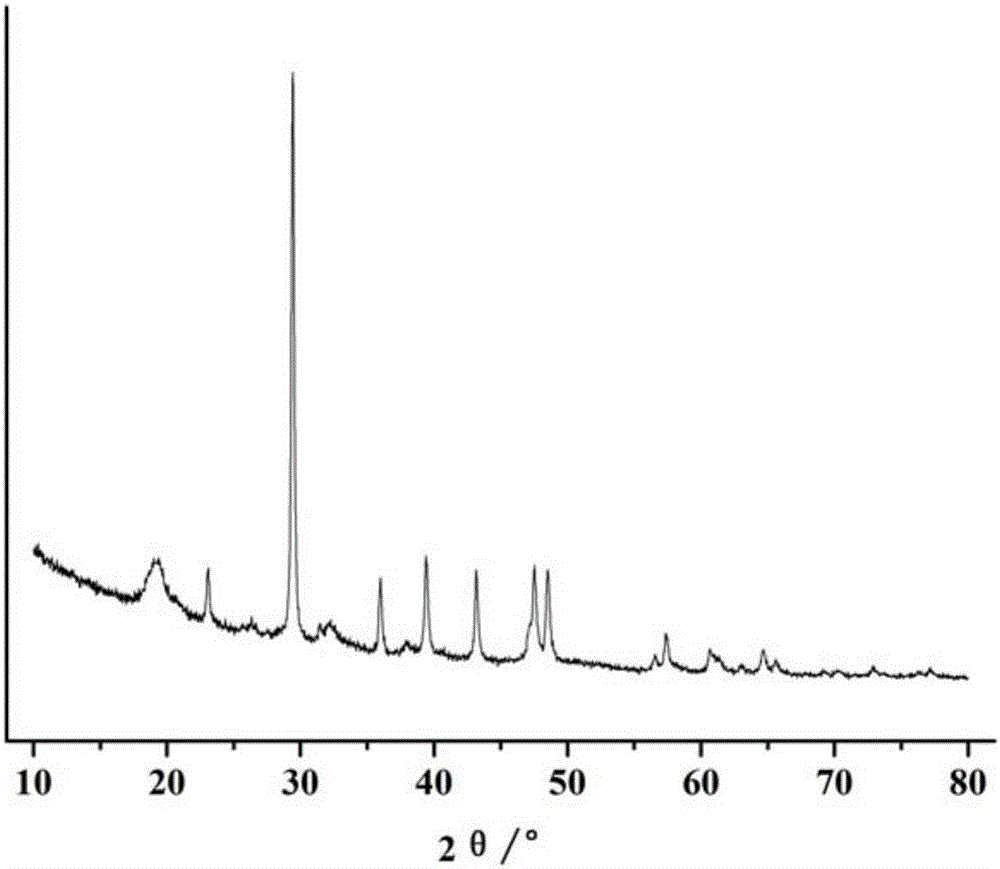

[0035] From figure 1 The diffraction peaks of calcium carbonate and chitin can be seen in the X-ray diffraction pattern of image 3 From the particle size distributio...

Embodiment 2

[0037] 1) Use the flotation method to remove the residual meat on the crab shell of the stone crab, drum dry, and pulverize; then the powder is subjected to subsequent processing in sequence;

[0038] 2) Mix 1 mass part of coarsely crushed crab shell powder with 10 mass parts of a 1% potassium hydroxide solution, stir at room temperature for 24 hours, remove protein and fat, press filter, and wash with water until neutral ;

[0039] 3) Add 10 parts by mass of potassium permanganate solution with a mass concentration of 0.1% to the powder, stir at room temperature for 24 hours to decolorize the powder, press filter, wash with water until the filtrate is colorless, add water and stir at a high speed to obtain the powder pulp;

[0040] 4) Wet grinding in a horizontal sand mill, press filtration, drum drying, and crushing to obtain calcium carbonate-chitin composite powder.

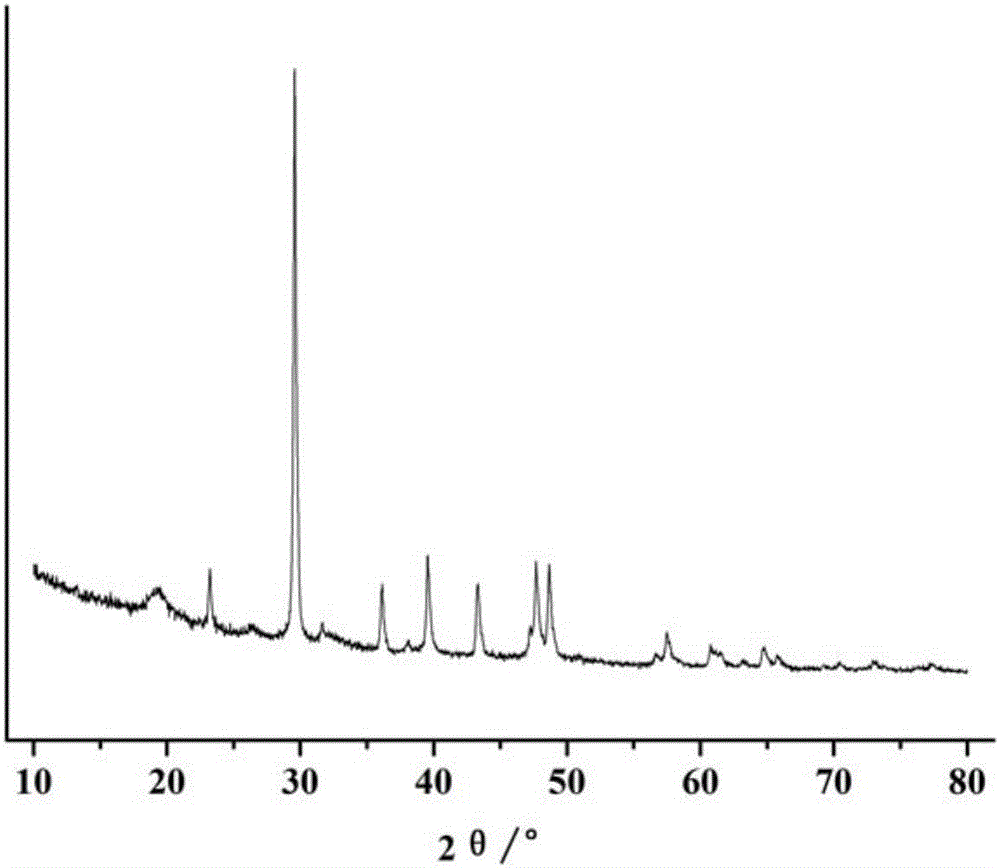

[0041] From figure 2 The diffraction peaks of calcium carbonate and chitin can be seen in the X-ray di...

Embodiment 3

[0043] 1) Use flotation to remove the residual meat on the crab shell of Portunus trituberculatus, drum dry, and pulverize; then the powder is subjected to follow-up treatment in sequence;

[0044] 2) Mix 1 mass part of coarsely crushed crab shell powder with 5 mass parts of a 5% calcium hydroxide solution, stir at 50°C for 10 h, remove protein and fat, press filter, and wash with water until medium sex;

[0045] 3) Add 5 parts by mass of sodium hypochlorite solution with a mass concentration of 2% to the powder, stir at 50° C. for 10 h, decolorize the powder, press filter, wash with water until the filtrate is colorless, add water and stir at a high speed to obtain a slurry;

[0046] 4) Place in a stirring mill for wet grinding, press filter, drum dry, and pulverize to obtain calcium carbonate-chitin composite powder.

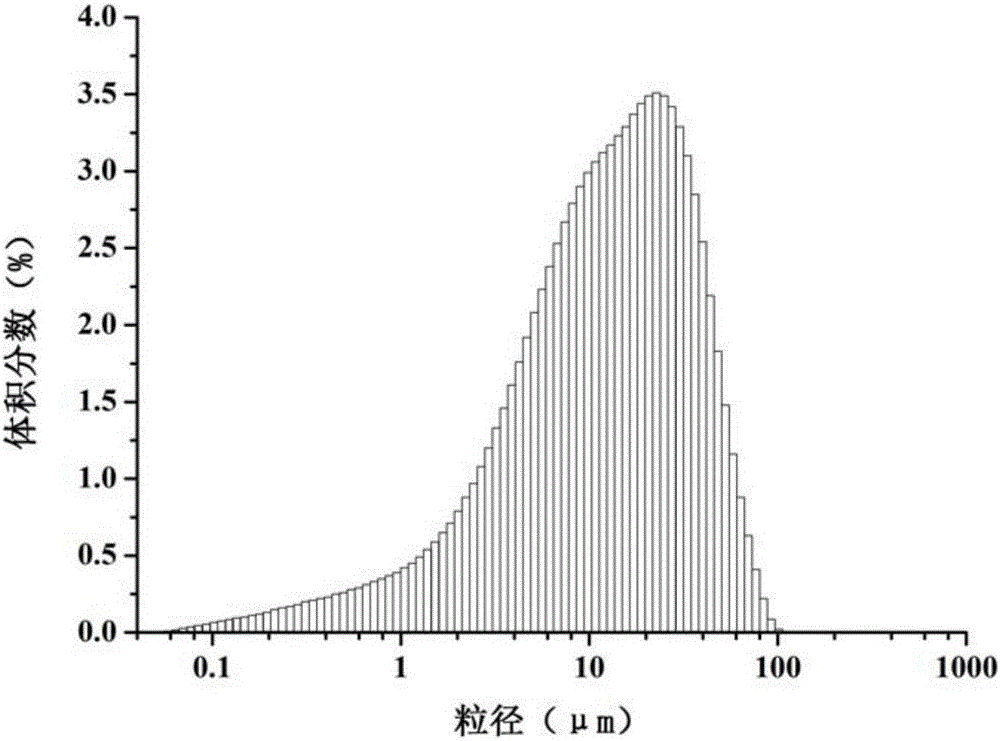

[0047] From Figure 5 From the particle size distribution curve, it can be seen that the average particle size of the sample is about 12 μm, and the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com