Uniaxially stretched multilayer laminate film, and optical member comprising same

A technology of uniaxial stretching and lamination of films, applied in optical elements, optical elements, optics, etc., can solve limited and difficult to fully ensure the adhesion of the prism layer, and reduce the reactivity of thermosetting crosslinking agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0238]

[0239] Next, the method for producing the uniaxially stretched multilayer laminated film of the present invention will be described in detail.

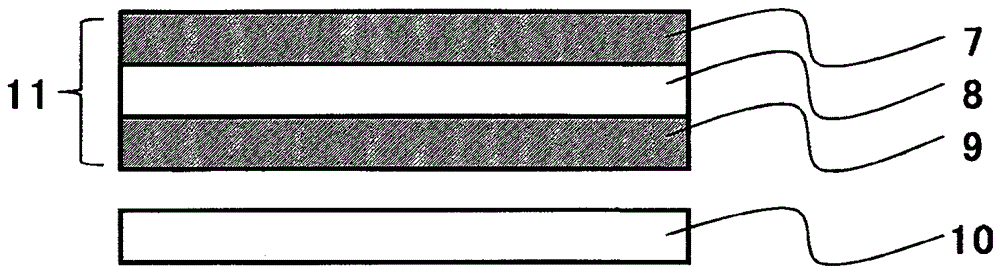

[0240] In the uniaxially stretched multilayer laminate film of the present invention, a polymer constituting the first layer and a polymer constituting the second layer are alternately laminated in a molten state to prepare an alternate laminate of a total of 101 or more layers or a total of 300 or less layers , preferably on both sides of which a layer of thick film (buffer layer) is provided, and the alternate laminate with the buffer layer is divided into, for example, 2 to 4 parts using a device called layer doubling, taking the alternate laminate with the buffer layer as 1 Blocks are laminated again so that the number of layers (multiplication number) of the block becomes 2 to 4 times, and the above-mentioned method can be used to increase the number of layers. By such a method, it is possible to obtain an intermediate...

Embodiment 1-1

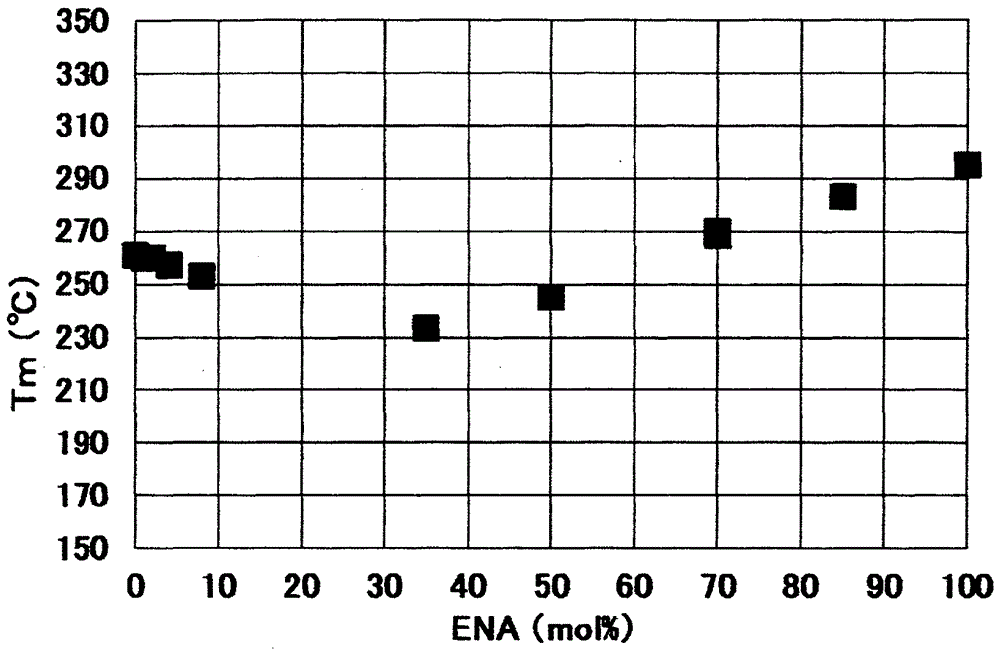

[0375] As the polyester for the first layer, dimethyl 2,6-naphthalene dicarboxylate, dimethyl terephthalate, and ethylene glycol were transesterified in the presence of titanium tetrabutoxide, followed by polycondensation. Prepare 95 mol% of the acid component as a 2,6-naphthalene dicarboxylic acid component (represented as PEN in the table), 5 mol% of the acid component as a terephthalic acid component (represented as DMT in the table), and the diol component as Copolyester of ethylene glycol (DMT5PEN) (intrinsic viscosity 0.64dl / g).

[0376] In addition, as the polyester for the second layer, dimethyl 2,6-naphthalene dicarboxylate, dimethyl terephthalate, ethylene glycol, and trimethylene glycol were transesterified in the presence of titanium tetrabutoxide , and then continue the polycondensation reaction, prepare 50 mol% of the acid component as 2,6-naphthalene dicarboxylic acid component (recorded as PEN in the table), and 50 mol% of the acid component as terephthalic aci...

Embodiment 1-2~1-4

[0380] [Example 1-2~1-4, Comparative Example 1-1~1-2]

[0381] As shown in Table 1-1, except that the resin composition of each layer, layer thickness, and stretching conditions were changed, it carried out similarly to Example 1-1, and obtained the uniaxially stretched multilayer laminated film. The resin composition of each layer of the uniaxially stretched multilayer laminated film obtained as described above, the characteristics of each layer, and the physical properties of the uniaxially stretched multilayer laminated film are shown in Table 1-1.

[0382] [Coating solution 1-A]

[0383] (acrylic adhesive)

[0384] It consists of 60 mol% methyl methacrylate / 30 mol% ethyl acrylate / 5 mol% 2-hydroxyethyl acrylate / 5 mol% N-methylolacrylamide (Tg=40°C). In a four-necked bottle, put 302 parts of ion-exchanged water and raise the temperature to 60° C. in a nitrogen stream, then add 0.5 parts of ammonium persulfate and 0.2 parts of sodium bisulfite as a polymerization initiator,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| degree of polarization | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com