High throughput screening system, screening method and preparation method for chlorella functional component CPE

A functional ingredient, chlorella technology, applied in biochemical equipment and methods, material excitation analysis, microbial determination/inspection, etc., can solve problems such as wall breaking, and achieve the effect of high functional activity and wide range of activity spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A high-throughput activity screening system for CPE, a functional component of Chlorella algae

[0082] 1) Antioxidant test: Griess reagent is used for testing, and the total antioxidant capacity and the scavenging effect on free radicals of the sample are detected by spectrophotometry;

[0083] 2) Cellular immune regulation test:

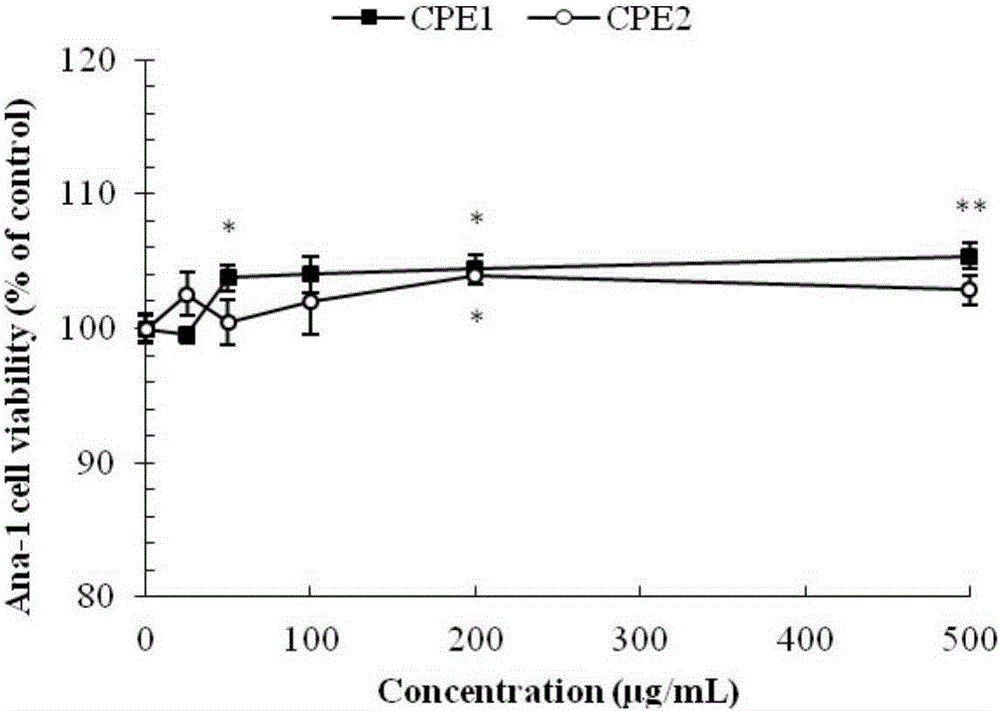

[0084] a. The effect of tetrathiazolium blue MTT assay components on the survival rate of mouse macrophage Ana-1;

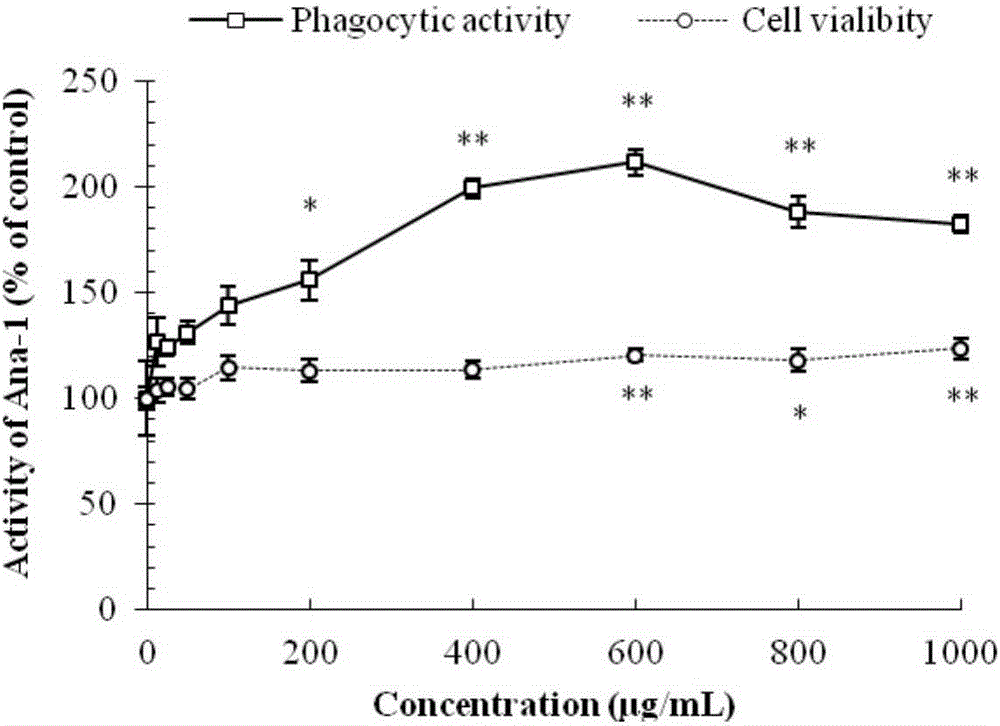

[0085] b. Neutral red NR staining method to detect the effect of components on Ana-1 phagocytosis;

[0086] c. Fluorescence probe method was used to detect the change of NO secretion in Ana-1 cells by samples;

[0087] 3) Redox metal ion chelation test:

[0088] a. Using ferrozine as Fe 2+ Chelating reagent, detection of Fe in samples by spectrophotometry 2+ Chelation ability;

[0089] b. Using catechol violet as Cu 2+ Chelating reagent, Cu detection of samples by spectrophotometry 2+ Chelation ability;

[0090] 4) Inh...

Embodiment 2

[0094] In this example, CPE1 and CPE2 were selected to be prepared by ultrasonic enzymolysis, and the specific method was as follows: 10 g of Chlorella pyrenoidosa powder was evenly suspended in 100 mL of distilled water. After ultrasonically disrupting the wall for 30 min, extract in a water bath at 95°C for 30 min. After the extract is cooled, cellulase (80 mg / g algae powder) and pectinase (10 mg / g algae powder) are added. Degrade the polysaccharide in a water bath at 50°C for 2 hours. Boiling water bath for 30min to inactivate the enzyme, centrifuge at 10000rpm for 30min. The supernatant was collected, concentrated by 4 times volume, and freeze-dried to obtain CPE sonication hydrolysis products, wherein CPE1 was hydrolyzed for 4 hours, and CPE2 was hydrolyzed for 16 hours.

[0095] A high-throughput activity screening method for CPE, a functional component of Chlorella algae

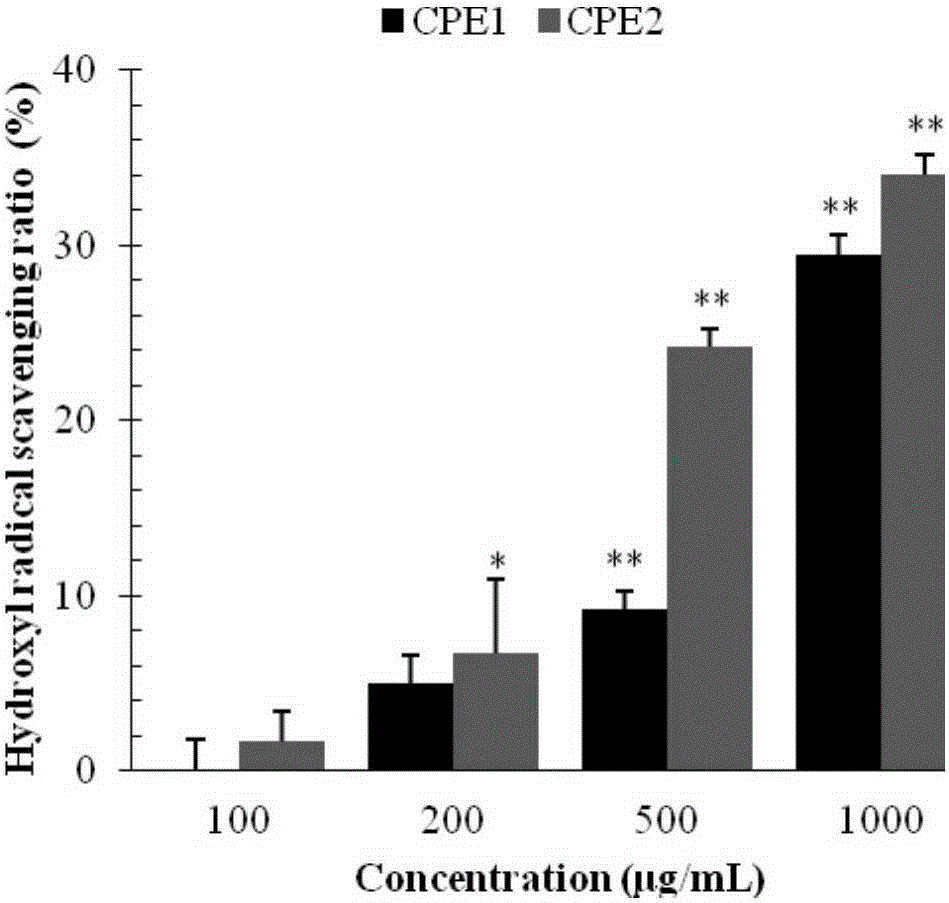

[0096] 1) Antioxidant ability test, that is, the ability to scavenge hydroxyl radicals (˙OH)

...

Embodiment 3

[0126] Method for preparing chlorella functional component CPE based on high pressure wall breaking method

[0127] Take 10g of Chlorella pyrenoidosa algae powder and suspend evenly in 100mL of distilled water. Place in a pressure cooker, heat at 0.15MPa, 120°C for 40min. The samples were taken out and cooled at room temperature. Centrifuge at 10,000 rpm for 30 min, and the supernatant is filtered under reduced pressure and stored at 4°C for later use. Add 100mL of distilled water to resuspend the centrifuged algae mud, place in a pressure cooker, heat at 0.15MPa, 120°C for 40min, and extract again. The samples were taken out and cooled at room temperature. Centrifuge at 10,000 rpm for 30 min, take the supernatant, and filter under reduced pressure. The two filtrates were combined and freeze-dried to obtain a CPE extract powder, labeled as CPE-a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com