Visual self-driven ultraviolet photoelectric detector and preparation method thereof

A technology of electrical detectors and ultraviolet light, which is applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of being easily corroded by ultraviolet rays, difficult to apply, and high breakdown electric field, and achieves low preparation costs and short response time , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

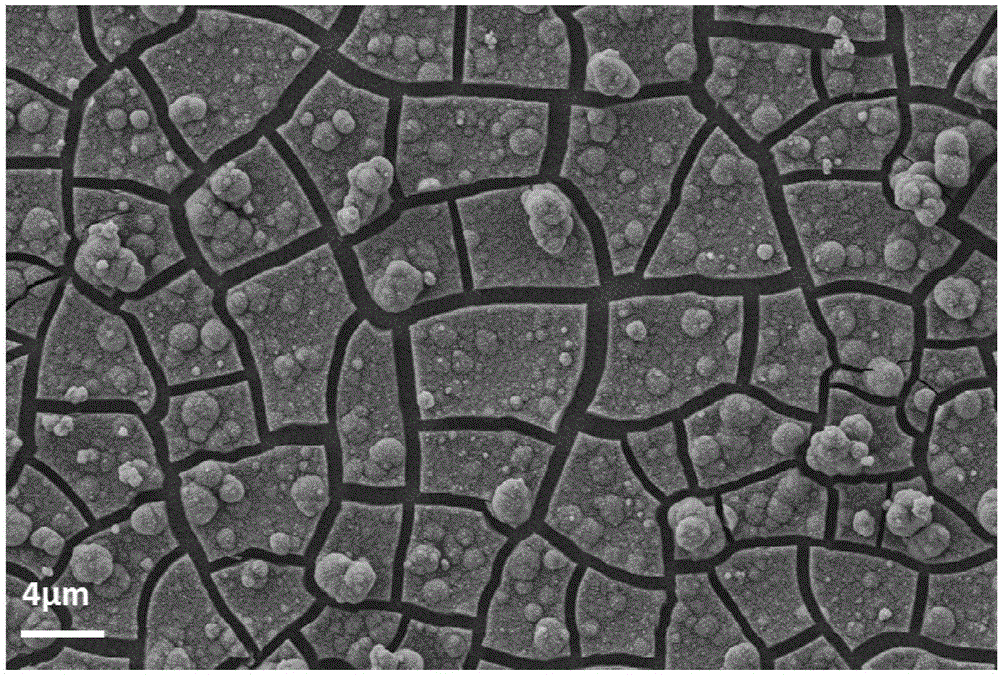

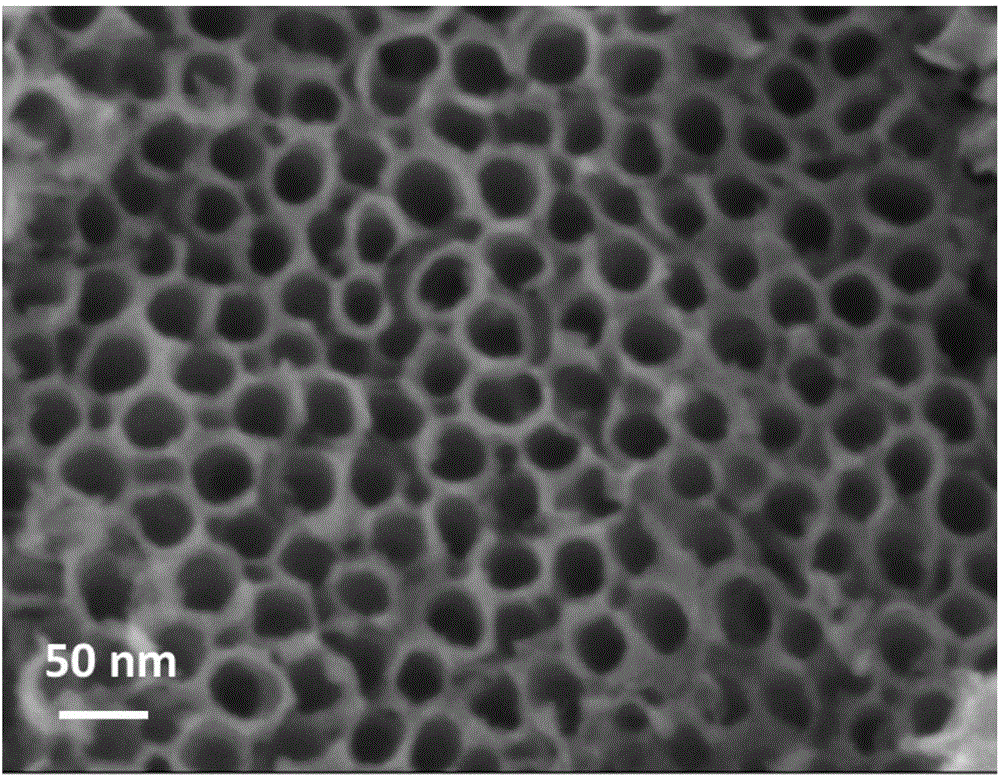

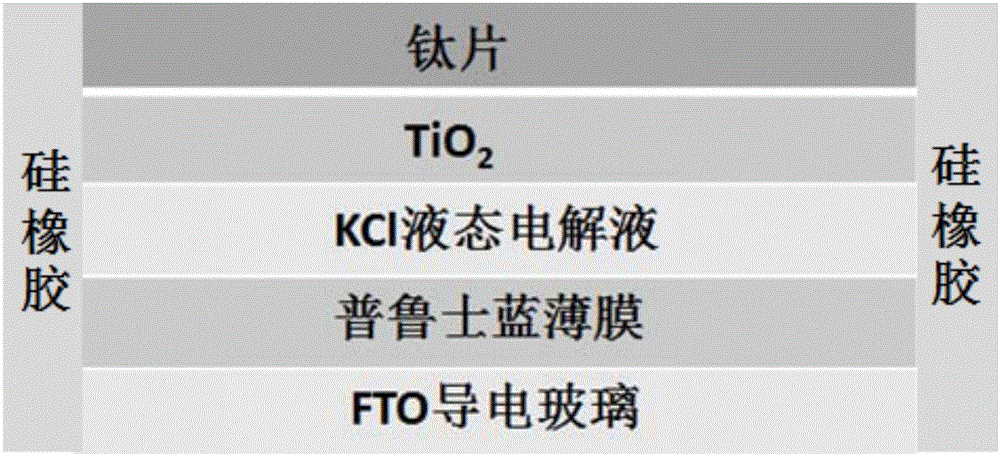

[0044] (1) The titanium sheet was polished smooth with sandpaper, and after ultrasonic cleaning with acetone, deionized water and alcohol in sequence, the 4 F and 2vol% deionized water in ethylene glycol solution were used for anodic oxidation of two electrodes, wherein platinum wire was used as the counter electrode. The oxidation voltage is 20V, and the oxidation time is 30min, so as to obtain TiO 2 nanotube array stock, and then the resulting TiO 2 The nanotube array blank is annealed at 450°C for 30-60min to finally obtain TiO 2 array of nanotubes. TiO 2 Scanning electron microscope (SEM) image of the nanotube array figure 2 shown.

[0045] (2) Clean the FTO conductive glass sequentially with acetone, deionized water and alcohol, and place it in a drying box for drying. Place the dried FTO conductive glass on Fe 2 (SO 4 ) 3 and K 3 [Fe(CN) 6 ] in a mixed solution of constant current electrochemical deposition, the constant current is -40μA·cm -2 , the depositio...

Embodiment 2

[0048] (1) The FTO conductive glass is ultrasonically cleaned with acetone, deionized water and alcohol in sequence, and then dried. Place the cleaned and dried FTO conductive glass in a 200mL hydrothermal kettle, then add hydrochloric acid (concentration: 36wt%), deionized water (30mL) and TiCl with a volume ratio of 25:25:0.6 4 The mixed solution is then hydrothermally heated at 140°C for 12h to obtain TiO 2 Nanowire Array Stock. Finally, the resulting TiO 2 The nanowire array blank was annealed at 450°C for 30-60min to obtain TiO 2 array of nanowires.

[0049] (2) Clean the FTO conductive glass sequentially with acetone, deionized water and alcohol, and then dry it; place the dried FTO conductive glass on Fe 2 (SO 4 ) 3 and K 3 [Fe(CN) 6 ] in the mixed solution of galvanostatic electrochemical deposition, and the galvanostatic control was -40μA·cm -2 , the deposition time is 5min, and the Prussian blue film is finally obtained. The Fe 2 (SO 4 ) 3 and K 3 [Fe(C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com