A zwitterionic ternary compound flooding produced water degreaser

A ternary compound and amphoteric ion technology, applied in mining wastewater treatment, separation methods, liquid separation, etc., can solve the problems of poor demulsification effect, unsuitable oil removal treatment, etc., achieve high oil removal efficiency, easy to obtain and transport Preservation and Viscosity Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Degreaser K 1 and its preparation method

[0031] (1) Degreaser K 1 The composition, components and molecular formula are as follows:

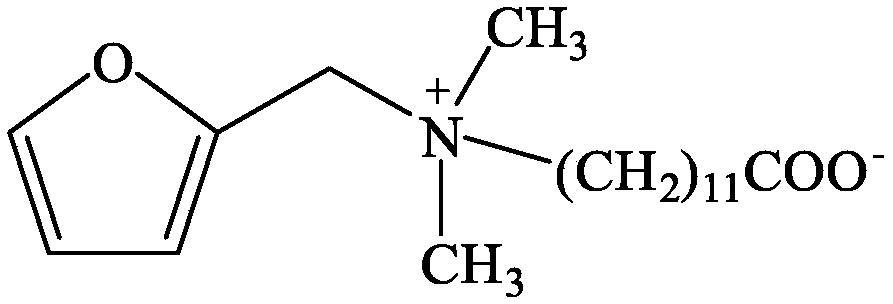

[0032] Degreaser K 1 The degreaser is an intermediate formed by the reaction of 2-furan methylamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to generate a zwitterionic degreaser, in which 2-furyl methylamine, formaldehyde, formic acid and chlorodeca The mol ratio of sodium dioxate is 1: 1.25: 1.5: 1.5, and molecular formula is as follows:

[0033]

[0034] (2) Degreaser K 1 The preparation method is as follows:

[0035] ①Add 1mol of 2-furylmethylamine and 777g of benzene into a three-necked flask, install a reflux condenser with a water separator, stir at 230rpm, heat up to 35°C, pour 1.5mol of formic acid into the constant pressure drops In the liquid funnel, control the titration speed so that the formic acid is dripped within 40min. After the formic acid is dripped, adju...

Embodiment 2

[0039] Embodiment 2: Degreaser K 2 and its preparation method

[0040] (1) Degreaser K 2 The composition, components and molecular formula are as follows:

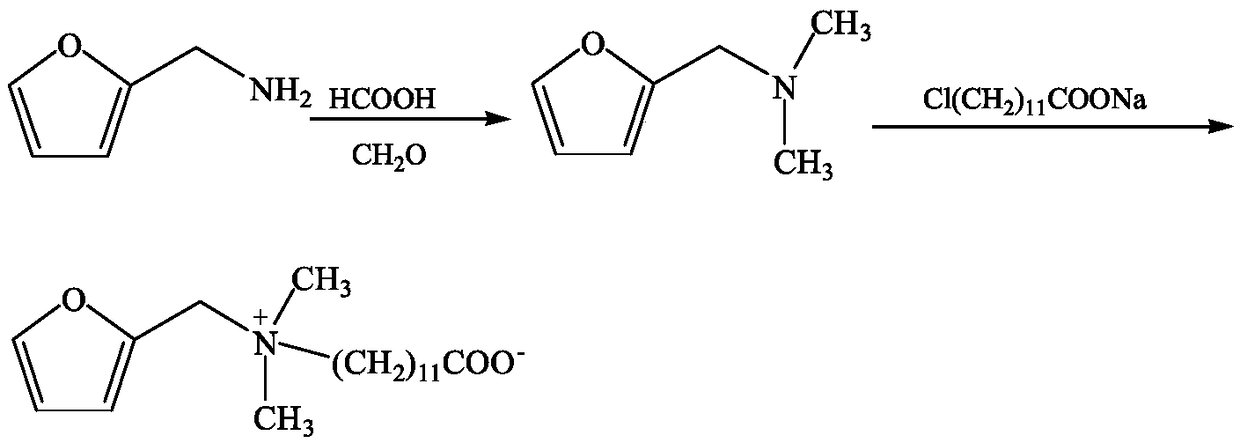

[0041] Degreaser K 2 The degreaser is an intermediate formed by the reaction of 2-furan methylamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to generate a zwitterionic degreaser, in which 2-furyl methylamine, formaldehyde, formic acid and chlorodeca The mol ratio of sodium dioxate is 1: 2.5: 4: 2, and molecular formula is as follows:

[0042]

[0043] (2) Degreaser K 2 The preparation method is as follows:

[0044] ① Add 1mol of 2-furylmethylamine and 985g of benzene into a three-necked flask, install a reflux condenser with a water separator, stir at 280rpm, heat up to 32°C, pour 4mol of formic acid into the constant pressure drop In the funnel, control the titration speed so that the formic acid is dripped within 45 minutes. After the formic acid is dripped, adjust the stir...

Embodiment 3

[0048] Embodiment 3: Degreaser K 3 and its preparation method

[0049] (1) Degreaser K 3 The composition, components and molecular formula are as follows:

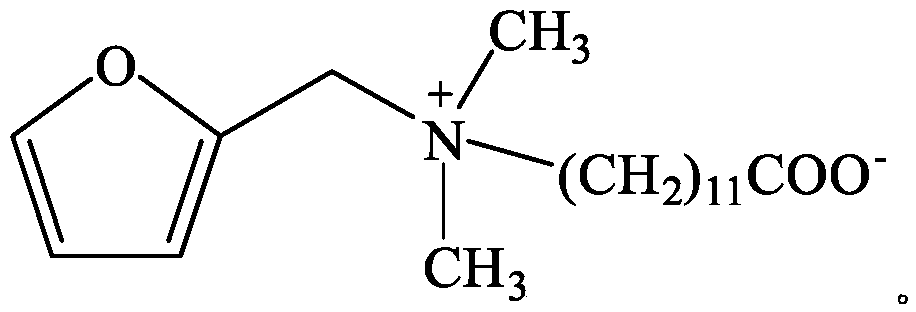

[0050] Degreaser K 3 The degreaser is an intermediate formed by the reaction of 2-furan methylamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to generate a zwitterionic degreaser, in which 2-furyl methylamine, formaldehyde, formic acid and chlorodeca The mol ratio of sodium dioxate is 1: 4.5: 6: 3, and molecular formula is as follows:

[0051]

[0052] (2) Degreaser K 1 The preparation method is as follows:

[0053] ①Add 1mol of 2-furylmethylamine and 1230g of cyclohexanol into a three-necked flask, install a reflux condenser with a water separator, stir at 200rpm, heat up to 30°C, pour 6mol of formic acid into a constant pressure In the dropping funnel, control the titration speed so that the formic acid is dripped within 50 minutes. After the formic acid is dripped, adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com