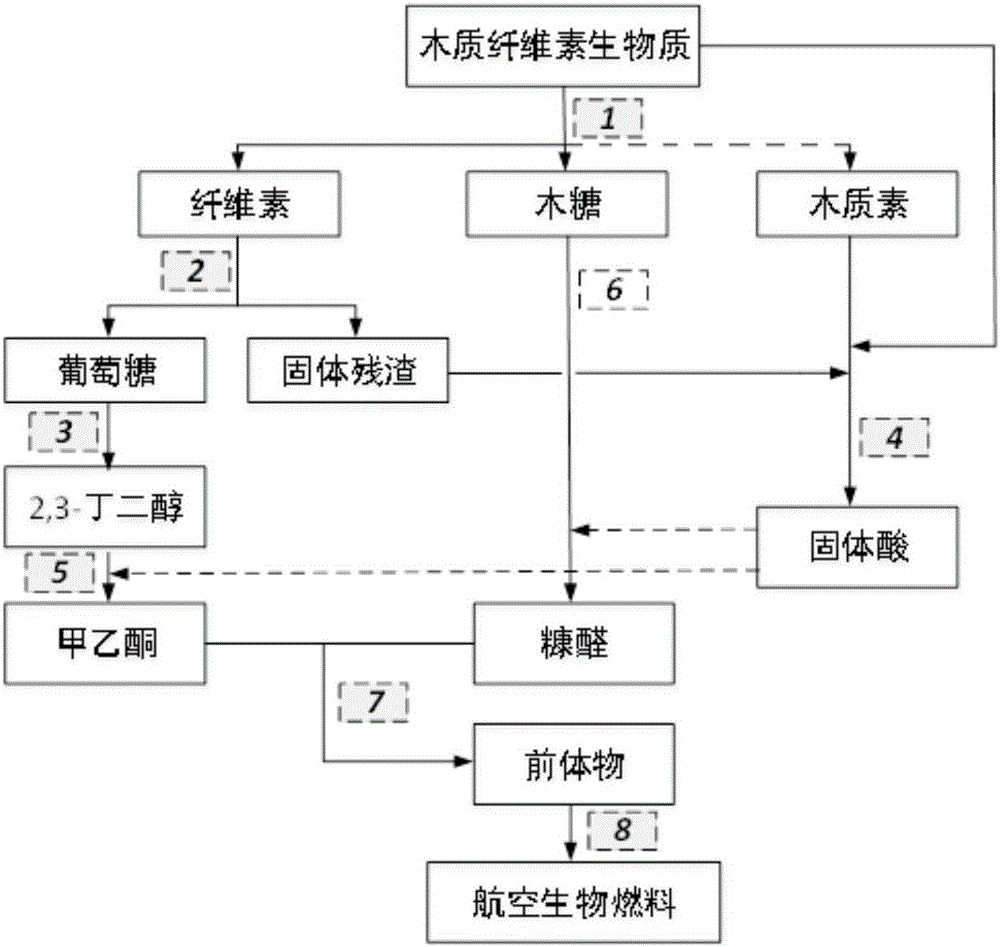

Method for preparing whole biomass base aviation biofuel

A biofuel and biomass technology, applied in the direction of biological raw materials, fuels, liquid carbon-containing fuels, etc., can solve the problems such as the preparation process of biomass-based aviation fuel needs to be improved, and the physical properties and combustion performance do not match.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

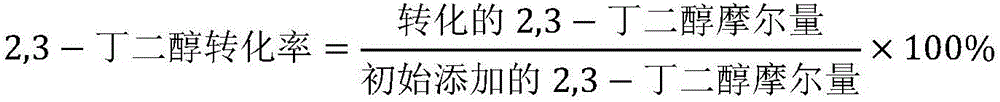

Method used

Image

Examples

Embodiment 1

[0052] The dilute acid pretreatment of embodiment 1 lignocellulosic raw material

[0053] The lignocellulosic biomass raw material used is wheat straw, which is produced in Shandong Province. After the wheat straw is crushed, the part with a particle size of 20-60 mesh is taken, and the main components of the wheat straw used are analyzed according to the lignocellulose component determination method of the American Renewable Energy Laboratory. The results are: moisture 4.6%, dextrose Sugar 35.2%, xylan 21.4%, arabinan 2.8%, lignin 21.1%, ash 6.6%, other soluble solids 8.3%.

[0054] Mix the wheat straw raw material with the sulfuric acid solutions of different concentrations shown in the table below according to the ratio of solid to liquid of 1:10kg / L, then stir and pretreat in the autoclave for 30 minutes at the temperature shown in the table below, and then filter to obtain the pretreated solid (i.e. cellulose solids) and xylose solution. The pretreated solids were fully...

Embodiment 2

[0057] The formic acid classification pretreatment of embodiment 2 lignocellulosic raw material

[0058] The lignocellulosic raw material used is the same as in Example 1. Adopt mass concentration to be the formic acid aqueous solution of 75% at the liquid-solid ratio (L / kg) of 10:1 under the condition of 107 ℃ of pretreatment (being soaking treatment) 1h, the mixture adopts vacuum filtration after pretreatment, and the solid matter obtained adopts and During the pretreatment process, formic acid of the same concentration is washed once at a liquid-solid ratio of 5:1 based on the dry weight of the initial solid, and then vacuum-filtered. The solid matter is evaporated under reduced pressure at 90°C and 5kpa absolute pressure to recover most of the formic acid. The obtained solid (i.e. cellulose solid) is fully washed with tap water and then enzymatically hydrolyzed for 120 h at 5% solid concentration, 0.5 g / L Tween 20, pH 4.8, and 50 degrees Celsius with a cellulase dosage of ...

Embodiment 3

[0059] Embodiment 3 xylose is converted into furfural under sulfuric acid catalysis

[0060]After adding 3% by mass of sulfuric acid to the xylose solution in Example 1, heat it in an autoclave. During the reaction, the furfural vapor generated is released intermittently through the gas phase extraction port at the top of the reactor, thereby reducing the amount of furfural in the high-temperature reaction system. residence time to avoid side reactions or degradation of furfural. The reaction temperature was controlled at 175°C, the total reaction time was 180min, the final yield of furfural was 49.5%, and the selectivity was 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com