Preparation method of buckwheat extract

A kind of buckwheat extract and buckwheat technology, applied in the direction of food ingredients containing natural extracts, food extraction, food science, etc., can solve the problems of precipitation, rough feeling, obvious, etc., and achieve high product yield, strong buckwheat flavor, and nutrients many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

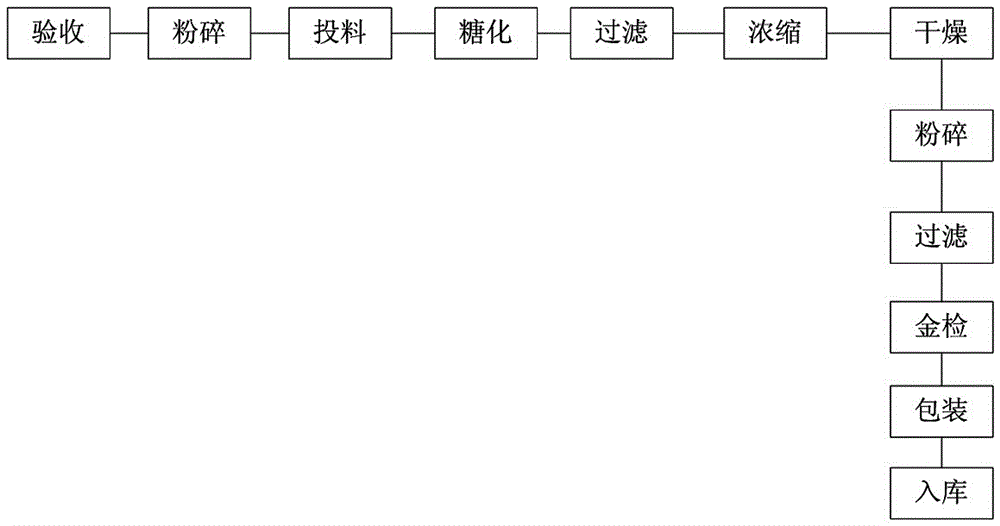

[0037] Such as figure 1 Shown, the preparation method of buckwheat extract of the present invention comprises the following steps:

[0038] Step 1: Buckwheat raw materials are crushed; the buckwheat raw materials are discharged from the steel silo, transported to the stone remover, iron remover, and grading screen by the horizontal screw conveyor and bucket elevator, and then crushed by the hammer mill and conveyed by gravity Pipeline transport to the temporary storage warehouse;

[0039] During the pulverization process of buckwheat raw materials, the pretreatment process is carried out on raw materials, puffing treatment is carried out under high temperature conditions, the rutin decomposing enzyme in buckwheat is inactivated, and pregelatinization is also carried out at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com