A kind of degreasing agent for three-element compound flooding produced water treatment and preparation method thereof

A technology of effluent treatment and ternary compounding, applied in the preparation of organic compounds, water/sewage treatment, preparation of amino compounds, etc., can solve the problems of inappropriate degreasing treatment of polymer-containing sewage, poor demulsification effect, etc. And transportation and preservation, high oil removal efficiency, good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Degreaser J 1 and its preparation method

[0032] (1) Degreaser J 1 The composition, components and molecular formula are as follows:

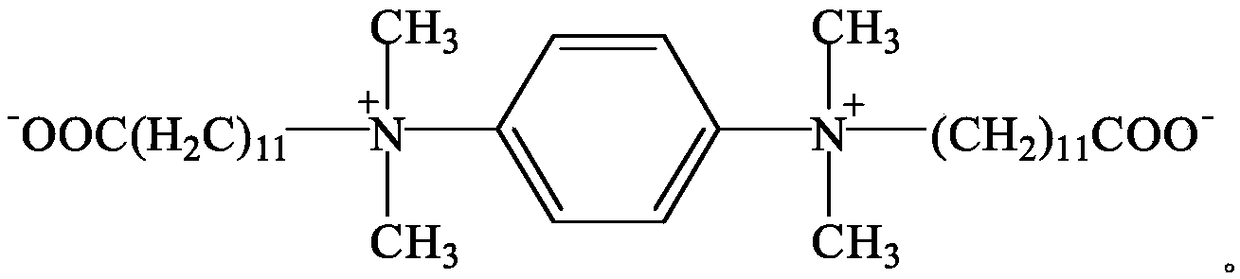

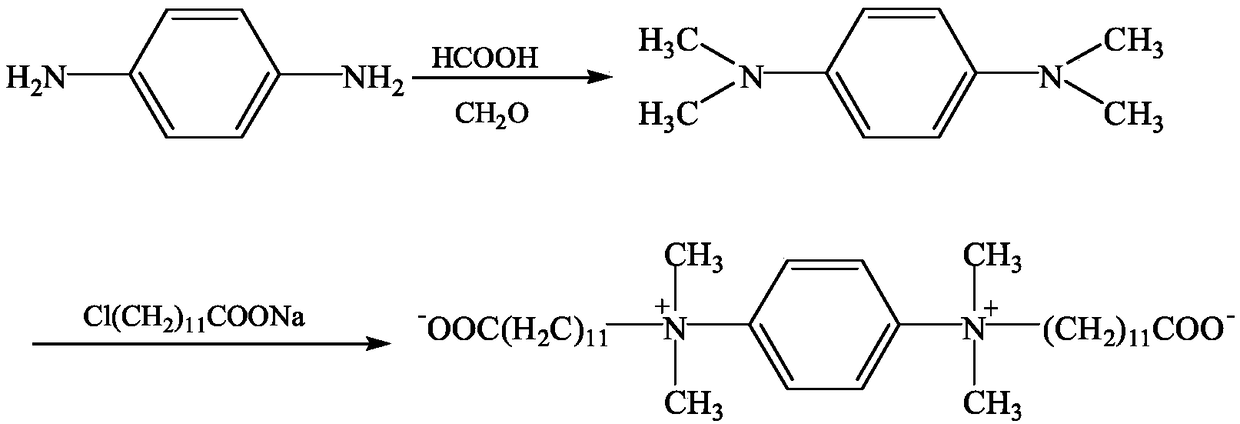

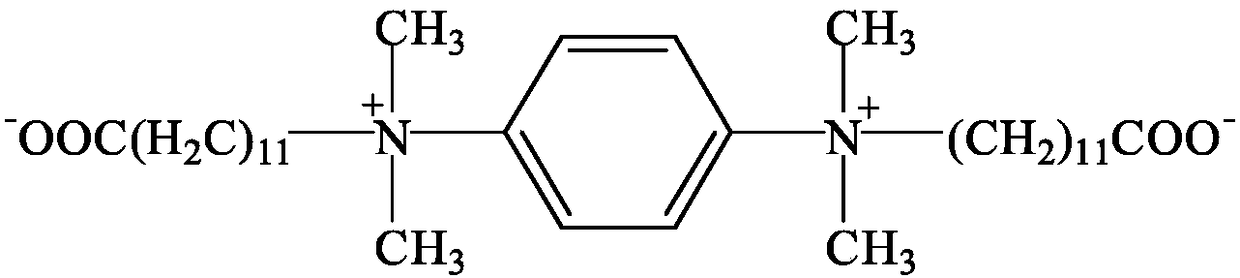

[0033] Degreaser J 1 The intermediate is formed by reacting p-phenylenediamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to form zwitterionic degreaser. Wherein, the molar ratio of p-phenylenediamine, formaldehyde, formic acid and sodium chlorododecanoate is 1:3:3:1. Degreaser J 1 The molecular formula is as follows:

[0034]

[0035] (2) Degreaser J 1 The preparation method is as follows:

[0036] ①Put 1mol of p-phenylenediamine and 1081.4g of isopropanol into a three-necked flask, install a reflux condenser with a water separator, stir at 200rpm, heat up to 30°C, pour 3mol of formic acid into a constant pressure In the dropping funnel, control the titration speed, and finish the dropping within 40 minutes. After the formic acid is dropped, adjust the stirring rate to 500...

Embodiment 2

[0040] Embodiment 2: Degreaser J 2 and its preparation method

[0041] (1) Degreaser J 2 The composition, components and molecular formula are as follows:

[0042] Degreaser J 2The intermediate is formed by reacting p-phenylenediamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to form zwitterionic degreaser. Wherein, the molar ratio of p-phenylenediamine, formaldehyde, formic acid and sodium chlorododecanoate is 1:4:4.5:1.25. Degreaser J 1 The molecular formula is as follows:

[0043]

[0044] (2) Degreaser J 2 The preparation method is as follows:

[0045] ①Put 1mol of p-phenylenediamine and 1522.3g of propanol into a three-necked flask, install a reflux condenser with a water separator, stir at 230rpm, heat up to 32°C, pour 4.5mol of formic acid into a constant pressure In the dropping funnel, control the titration speed, and finish dropping within 45 minutes. After the formic acid is dropped, adjust the stirring rate to 550 ...

Embodiment 3

[0049] Embodiment 3: Degreaser J 3 and its preparation method

[0050] (1) Degreaser J 3 The composition, components and molecular formula are as follows:

[0051] Degreaser J 3 The intermediate is formed by reacting p-phenylenediamine with formaldehyde and formic acid, and then reacted with sodium chlorododecanoate to form zwitterionic degreaser. Wherein, the molar ratio of p-phenylenediamine, formaldehyde, formic acid and sodium chlorododecanoate is 1:6:7:3.75. Degreaser J 1 The molecular formula is as follows:

[0052]

[0053] (2) Degreaser J 3 The preparation method is as follows:

[0054] ①Put 1mol of p-phenylenediamine and 2012.5g of isobutanol into a three-necked flask, install a reflux condenser with a water separator, stir at 260rpm, heat up to 36°C, pour 7mol of formic acid into a constant pressure In the dropping funnel, control the titration speed, and finish dropping within 55 minutes. After the formic acid is dropped, adjust the stirring rate to 520 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com