Preparation method of novel allicin microcapsules

A technology of allicin and microcapsules, which is applied in the field of preparation of new allicin microcapsules, can solve the problems of high price, easy agglomeration of microcapsules, and high bioavailability, and achieve low cost, high yield, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

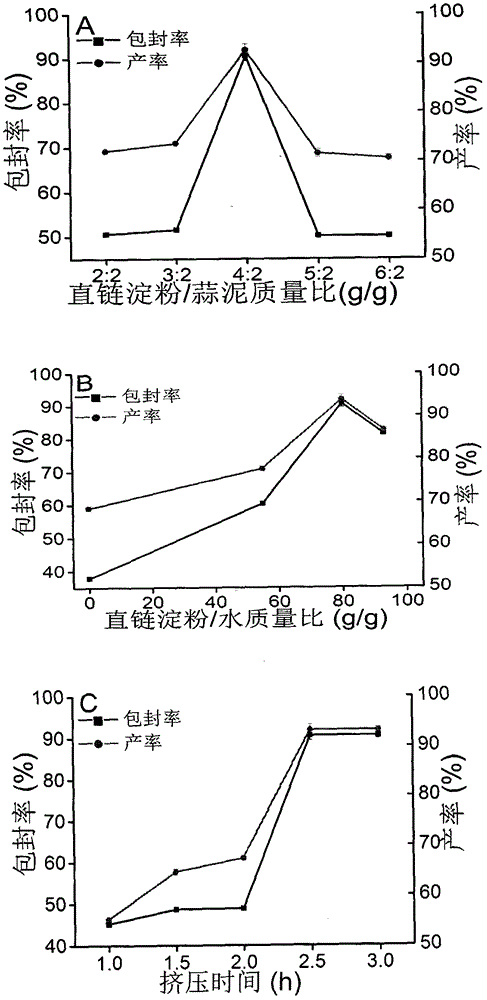

Embodiment 1

[0033] a. Peel fresh garlic, wash it, and squeeze it to make garlic paste;

[0034] b. Control the mass ratio of amylose and purified water to 4:5 to make a uniform wall material;

[0035] c. Make the mashed garlic and the wall material into a mixture according to the mass ratio of 2:4;

[0036] d. Fully extruding the mixture obtained above for 1 hour with an extruder, and drying at room temperature to obtain new allicin microcapsules.

[0037] The yield was 60.25%, and the embedding rate was 51.55%.

Embodiment 2

[0039] a. Peel fresh garlic, wash it, and squeeze it to make garlic paste;

[0040] b. Control the mass ratio of amylose and purified water to 4:4 to make a uniform wall material;

[0041] c. Make the mashed garlic and the wall material into a mixture according to the mass ratio of 2:4;

[0042] d. Fully extruding the mixture obtained above for 4 hours with an extruder, and drying at room temperature to obtain new allicin microcapsules.

[0043] The yield was 91.94%, and the embedding rate was 90.63%.

Embodiment 3

[0045] a. Peel fresh garlic, wash it, and squeeze it to make garlic paste;

[0046] b. Control the mass ratio of amylose and purified water to 3:4 to make a uniform wall material;

[0047] c. Make the mashed garlic and the wall material into a mixture according to the mass ratio of 2:4;

[0048] d. Using an extruder, fully extrude the mixture obtained above for 3 hours, and dry at room temperature to obtain new allicin microcapsules.

[0049] The yield was 70.25%, and the embedding rate was 50.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com