Diatomite composite material capable of adsorbing and degrading Cr(VI) and preparation method thereof

A composite material, adsorption degradation technology, applied in the field of heavy metal ion adsorption purification and toxic degradation materials, can solve the problems of low removal rate of heavy metal acid anions, difficult subsequent treatment of adsorbents, limited adsorption capacity, etc., to achieve good catalytic reduction ability, Improve adsorption efficiency, simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

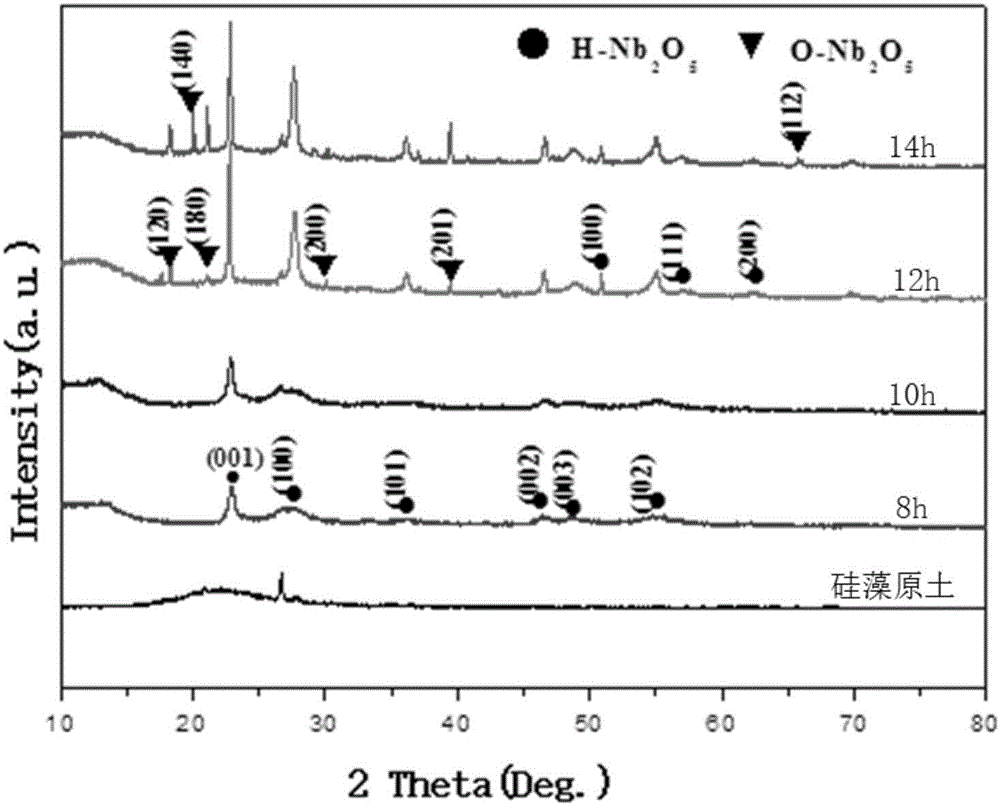

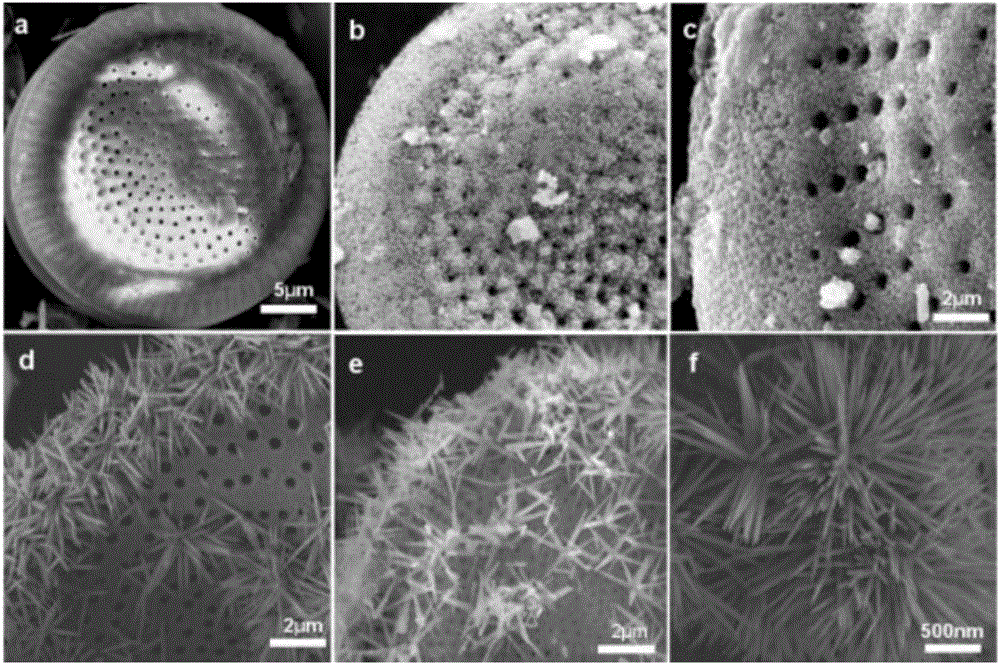

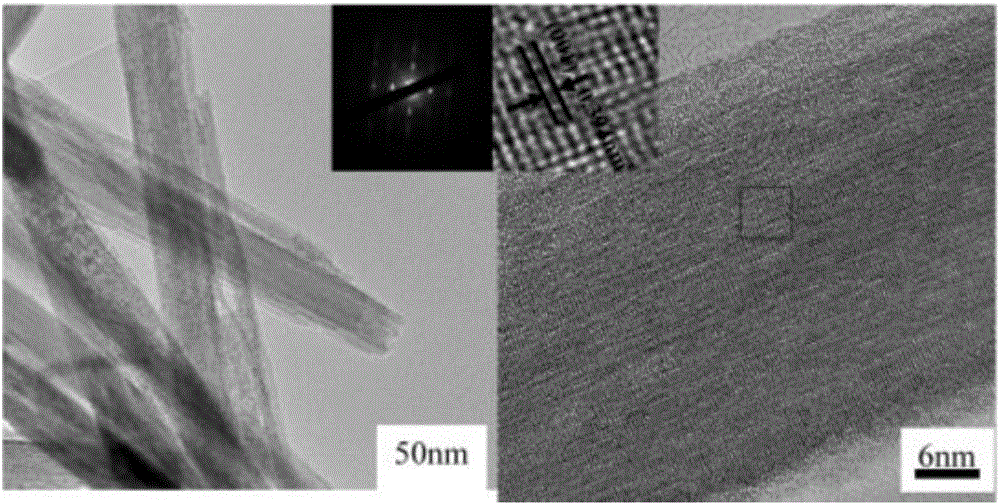

[0035] Embodiment 1 Solvothermal method prepares Nb 2 o 5 Nanorod / Diatomite Composite

[0036] (1) Weigh 0.5g of Nb 2 o 5 Put the powder into the reaction kettle, add 10mL of hydrofluoric acid to dissolve, then add ammonia water to precipitate, and make niobic acid powder for later use;

[0037] (2) Weigh 0.3g of niobic acid powder prepared in step (1), 0.5g of ammonium oxalate, 0.1g of sodium dodecylbenzenesulfonate, and 0.1g of diatomaceous earth, add them to 10mL of glacial acetic acid, and stir for 40min. Mix evenly to obtain a suspension;

[0038] (3) Transfer the suspension into a polytetrafluoroethylene reactor with a volume of 25 mL, place the reactor in an oven at 160° C. and heat it at a constant temperature for 14 hours; then take out the reactor, cool it to room temperature, filter the reaction product, and Wash 3-4 times with ethanol and deionized water, and dry at low temperature to obtain Nb2 o 5 Nanorod / Diatomaceous Earth Composite.

Embodiment 2

[0039] Embodiment 2 Solvothermal method prepares Nb 2 o 5 Nanorod / Diatomaceous Earth Composite

[0040] The only difference between the preparation method and Example 1 is that in step 2) when preparing the suspension, the amount of niobic acid powder added is 0.4 g.

Embodiment 3

[0041] Embodiment 3 Solvothermal method prepares Nb 2 o 5 Nanorod / Diatomaceous Earth Composite

[0042] The only difference between the preparation method and Example 1 is that in step 2) when preparing the suspension, the amount of niobic acid powder added is 0.5 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com