Fibroin/nylon composite material and preparing method thereof

A technology of nylon composite material and silk fibroin, which is applied in the field of regenerative medicine, can solve problems such as difficulty in obtaining effects, loss of silk flexibility, and limited improvement of mechanical properties, and achieves benefits for the transportation of nutrients, excellent mechanical properties, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Boil mulberry silk with 0.5% sodium bicarbonate solution for 30 minutes to degumming, and obtain silk fibroin fiber after repeating 3 times;

[0025] (2) Silk fibroin fiber is dissolved in 1.1% calcium chloride-98% formic acid solution, and the concentration of silk fiber dispersion is 5%;

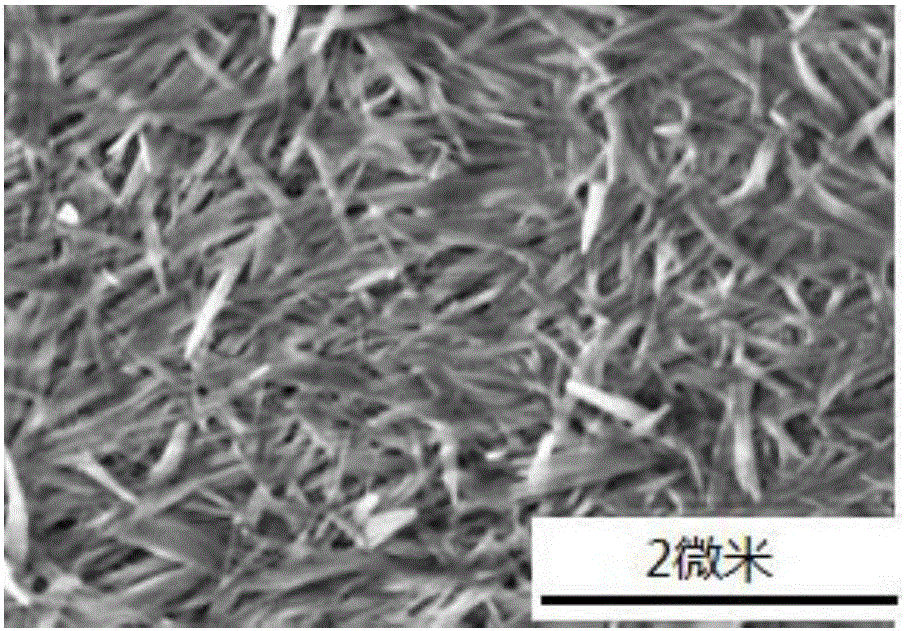

[0026] (3) Slowly drop the silk fiber dispersion into the sodium carbonate solution for mineralization reaction, the dropping time is 0.5h; the mass ratio of silk fiber to sodium carbonate is 1:0.1; filter, wash and dry the reacted solution Obtain white appearance, powdery calcium carbonate nanowires; figure 1 It is a scanning electron microscope picture of the above-mentioned calcium carbonate nanowire; it can be seen from the figure that the calcium carbonate wire has a diameter of 80-160nm, a length of about 650nm, and a high aspect ratio;

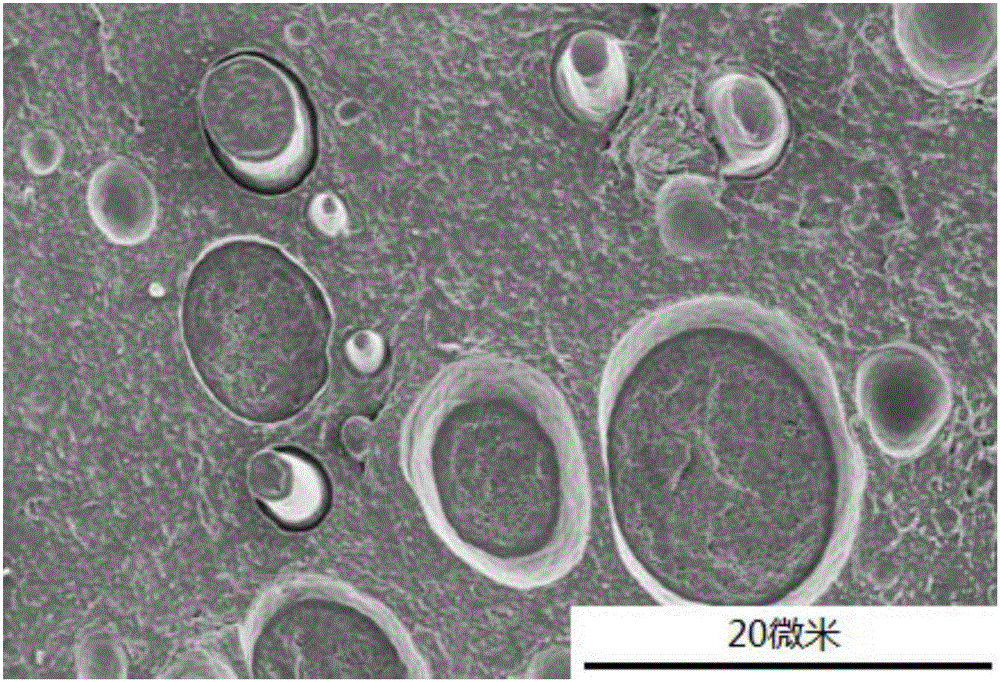

[0027] (4) Dissolve nylon 6 in the silk fiber dispersion in step (2); then add calcium carbonate nanowires in step (3) to obtain a blen...

Embodiment 2

[0029] (1) Boil mulberry silk with 0.5% sodium bicarbonate solution for 30 minutes to degumming, and obtain silk fibroin fiber after repeating 3 times;

[0030] (2) Silk fibroin fiber is dissolved in 1.6% calcium chloride-90% formic acid solution, and the concentration of silk fiber dispersion is 5%;

[0031] (3) Slowly drop the silk fiber dispersion into the sodium carbonate solution for mineralization reaction, the dropping time is 0.5h; the mass ratio of silk fiber to sodium carbonate is 1:0.1; filter, wash and dry the reacted solution Obtain white, powdery calcium carbonate nanowires; the calcium carbonate wires have a diameter of 90-150nm, a length of about 630nm, and a high aspect ratio;

[0032] (4) Dissolve nylon 66 in the silk fiber dispersion in step (2); then add calcium carbonate nanowires in step (3) to obtain a blended solution; cast on a template and dry naturally; the dried film is placed Soak in deionized water for 0.5h, and then dry at 60°C to obtain silk fi...

Embodiment 3

[0034] (1) Boil mulberry silk with 0.5% sodium bicarbonate solution for 30 minutes to degumming, and obtain silk fibroin fiber after repeating 3 times;

[0035] (2) Silk fibroin fiber is dissolved in 1.5% calcium chloride-98% formic acid solution, and the concentration of silk fiber dispersion is 10%;

[0036] (3) Slowly drop the silk fiber dispersion into the sodium carbonate solution for mineralization reaction, the dropping time is 0.5h; the mass ratio of silk fiber to sodium carbonate is 1:0.5; filter, wash and dry the reacted solution Obtain white, powdery calcium carbonate nanowires; the calcium carbonate wires have a diameter of 100-160nm, a length of about 670nm, and a high aspect ratio;

[0037] (4) Dissolve nylon 6 in the silk fiber dispersion in step (2); then add calcium carbonate nanowires in step (3) to obtain a blended solution; cast on a template and dry naturally; the dried film is placed Soak in deionized water for 1 hour, and then dry at 70°C for infrared t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com