Micro-capsule suspension agent type triazole bactericide as well as preparation method and application thereof

A technology of microcapsule suspensions and triazoles, which is applied in the field of pesticide preparations, can solve the problems of poor stability, large dosage, and poor drug efficacy, and achieve the effects of good pourability, reduced side effects, and significant drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

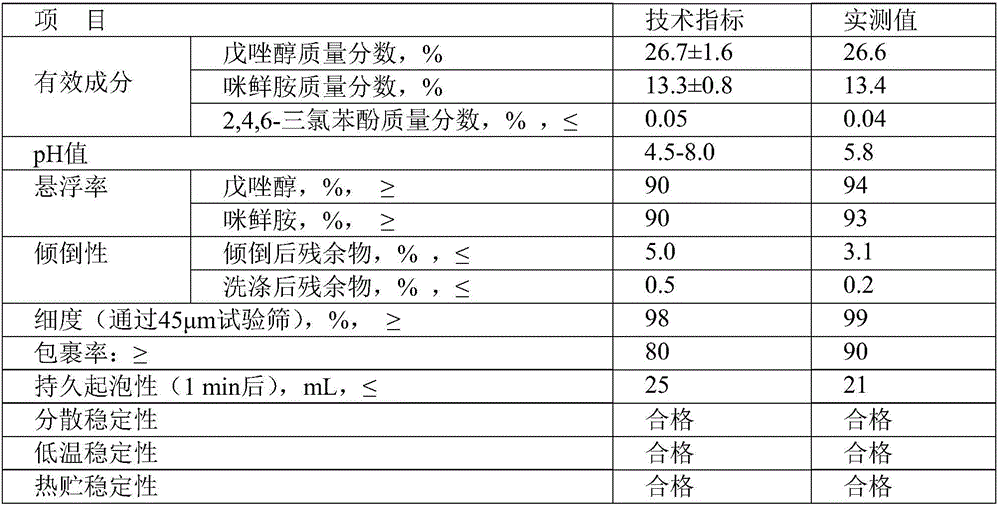

[0033] A microcapsule suspension type triazole fungicide, its composition and the mass percent of each component are: prochloraz 13.3%, tebuconazole 26.7%, alkylphenol polyoxyethylene ether 4% (emulsifier), Sodium methylene bis-naphthalene sulfonate 4% (dispersant), xanthan gum 0.3% (viscosity modifier), bentonite 3% (anti-caking agent), No. 100 solvent oil 10% (solvent oil), poly(formazol Vinyl ether / maleic acid) copolymer 5% (wetting agent), ethylparaben 0.5% (preservative), polymethylene polyisocyanate phenyl ester (CAS number: 9016-87- 9) 3.5% (capsule material), triethylenetetramine 1.5% (capsule material), and deionized water to make up 100%.

[0034] The preparation method of above-mentioned microcapsule suspension type triazole bactericide is:

[0035] The first step is to mix the polymethylene polyphenylisocyanate capsule skin material with prochloraz and solvent oil evenly in proportion, and set aside;

[0036] In the second step, the emulsifier, 40% dispersant and...

Embodiment 2

[0052] A microcapsule suspension type triazole fungicide, its composition and the mass percent of each component are: prochloraz 10%, epoxiconazole 25%, ethylene oxide propylene oxide block copolyether 3% ( Emulsifier), polycarboxylate and pyrrolidone mixture (mixed at 1:1) 5% (dispersant), carboxymethyl cellulose 0.8% (viscosity modifier), white carbon black 2% (anti-caking agent) , No. 150 solvent oil 8% (solvent oil), polydimethylsiloxane nonionic surfactant 4% (wetting agent), Kasone 0.1% (preservative), polymethylene polyisocyanate benzene Base ester 4% (capsule material), 1.6 hexamethylenediamine 1.6% (capsule material), deionized water to make up 100%.

[0053] The preparation method of above-mentioned microcapsule suspension type triazole bactericide is:

[0054] In the first step, mix polymethylene polyphenylisocyanate, prochloraz and solvent oil evenly in proportion, and set aside;

[0055] In the second step, the emulsifier, 50% dispersant and 55% water are mixed ...

Embodiment 3

[0063] A microcapsule suspension type triazole fungicide, its composition and the mass percent of each component are: prochloraz 30%, epoxiconazole 15%, ethylene oxide propylene oxide block copolyether 3.5% ( emulsifier), lignosulfonate 3% (dispersant), chitosan 1.3% (viscosity modifier), white carbon black 2.8% (anti-caking agent), No. 200 solvent oil 5% (solvent oil), Polydimethylsiloxane nonionic surfactant 3% (wetting agent), benzene sodium 1.5% (preservative), polymethylene polyisocyanate phenyl ester 5% (capsule material), 1.2- Hexamethylenediamine 2% (capsule material), deionized water to make up 100%.

[0064] The preparation method of above-mentioned microcapsule suspension type triazole bactericide is:

[0065] In the first step, mix polymethylene polyphenylisocyanate, prochloraz and solvent oil evenly in proportion, and set aside;

[0066] In the second step, the emulsifier, 45% dispersant and 60% water are mixed evenly in proportion, and set aside;

[0067] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com