Method of quickly and continuously depositing graphene on surface of electric-conductive fibers

A conductive fiber and graphene technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of uneven deposition, small improvement in the mechanical properties of conductive fibers, long electrophoresis time, etc., to achieve strong controllability and improve the surface Performance and wetting performance, low risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

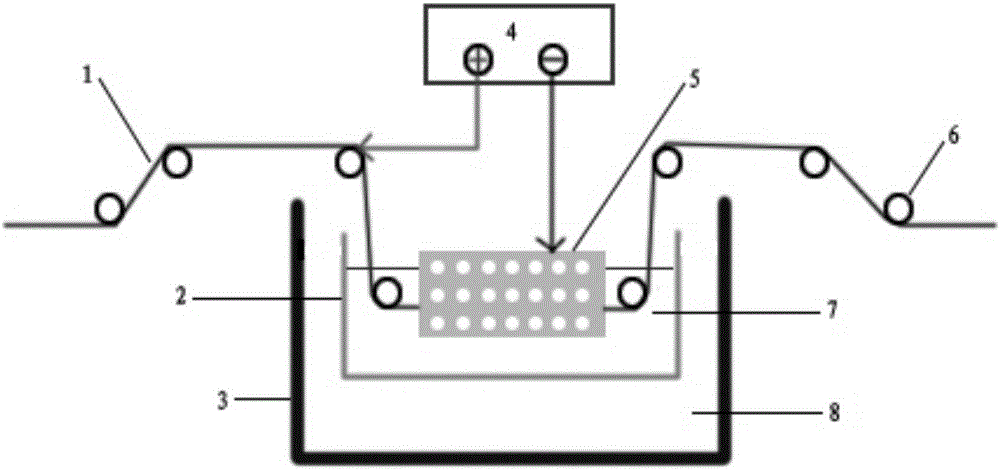

[0026] Specific embodiment one: the method for rapidly and continuously depositing graphene on the conductive fiber surface of the present embodiment is carried out according to the following steps:

[0027] 1. Preparation of graphene oxide solution: disperse graphene oxide and dispersant in a solvent, and use an ultrasonic cleaning machine to sonicate for 1 to 3 hours to form a uniformly dispersed graphene oxide solution;

[0028] 2. Conductive fiber desizing treatment: Add conductive fiber bundles and acetone to the extraction tube and extraction bottle of the Soxhlet extractor respectively, and heat the acetone in the extraction bottle at a heating temperature of 75-85°C to vaporize the acetone. The connecting pipe rises into the condenser, and the condensed liquid drips into the extraction tube to extract the sizing agent on the surface of the conductive fiber bundle; when the acetone liquid level in the extraction tube reaches a certain height, the acetone dissolved with t...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that the dispersant is polyvinylpyrrolidone, monoglyceride stearate or ethylene bisstearamide. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 1 in that the solvent is isopropanol, water, ethanol or dimethylformamide. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com