A kind of graphene/nickel phthalocyanine supercapacitor electrode material and preparation method thereof

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors to achieve the effects of good cycle stability, mild reaction conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

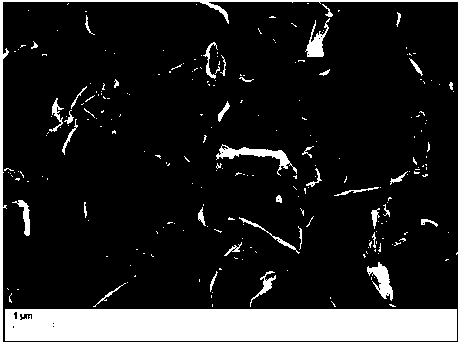

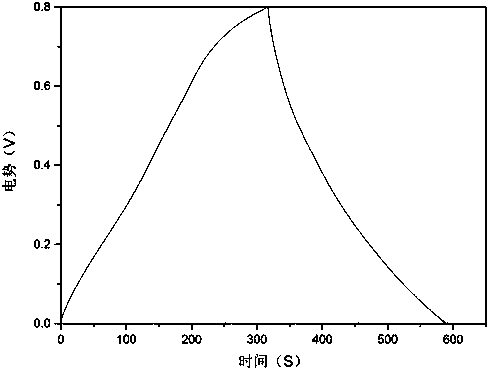

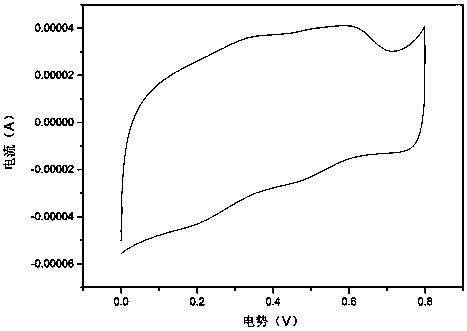

Image

Examples

Embodiment 1

[0038] (1) Preparation of functionalized reduced graphene (rGO-pPD): 300 mg of graphene oxide (GO) was weighed, dispersed in 300 ml of deionized water, 900 mg of p-phenylenediamine (pPD) was added, and after sonication for 1 h, under reflux conditions 240 μl of concentrated ammonia water with a concentration of 25 wt % was added to the bottom, reacted at 70° C. for 6 h, washed after the reaction was completed, and dried to obtain functionalized reduced graphene (rGO-pPD).

[0039](2) Preparation of tetranitronickel phthalocyanine (NiTNPc): urea (8.5g), 4-nitrophthalic acid (6.0g), nickel sulfate (1.8g), and ammonium chloride (0.6g) were successively Put it into the flask, add catalyst ammonium molybdate (0.08g) and 10ml nitrobenzene solvent under reflux conditions, heat to 120°C at 3°C / min, and react for 20min; heat the system to 170°C at 5°C / min, react After 3 hours, filter and wash; soak the filter cake in 250mL of 0.5mol / L dilute hydrochloric acid, boil for 10min, filter, a...

Embodiment 2

[0043] (1) Preparation of functionalized reduced graphene (rGO-pPD): Weigh 300 mg of graphene oxide (GO), disperse it in 300 ml of deionized water, add 100 mg of p-phenylenediamine (pPD), and sonicate for 1 h. 400 μl of concentrated ammonia water with a concentration of 25 wt % was added to the bottom, and the reaction was carried out at 100° C. for 24 h. After the reaction was completed, it was washed and dried to obtain functionalized reduced graphene (rGO-pPD).

[0044] (2) Preparation of tetranitro nickel phthalocyanine (NiTNPc): urea (10.0 g), 4-nitrophthalic acid (7.0 g), nickel chloride hexahydrate (2.2 g), ammonium chloride (0.8 g) g) add to the flask in turn, add catalyst ammonium molybdate (0.15g) and 10ml nitrobenzene solvent under reflux conditions, heat to 170°C at 3°C / min, and react for 60min; heat the system to 200°C at 5°C / min ℃, react for 8 hours, filter and wash; soak the filter cake in 250mL 2mol / L dilute hydrochloric acid, boil for 60min, filter, add 250mL ...

Embodiment 3

[0048] (1) Preparation of functionalized reduced graphene (rGO-pPD): 300 mg of graphene oxide (GO) was weighed, dispersed in 300 ml of deionized water, 500 mg of p-phenylenediamine (pPD) was added, and after sonication for 1 h, under reflux conditions 320 μl of concentrated ammonia water with a concentration of 25 wt % was added to the bottom, and the reaction was carried out at 85° C. for 15 h. After the reaction was completed, it was washed and dried to obtain functionalized reduced graphene (rGO-pPD).

[0049] (2) Preparation of tetranitro nickel phthalocyanine (NiTNPc): urea (9.25 g), 4-nitrophthalic acid (6.5 g), nickel chloride hexahydrate (2.0 g), ammonium chloride (0.7 g) g) Add to the flask in turn, add catalyst ammonium molybdate (0.115g) and 10ml nitrobenzene solvent under reflux conditions, heat to 145°C at 3°C / min, and react for 40min; heat the system to 185°C at 5°C / min ℃, after 5.5 hours of reaction, filter and wash; soak the filter cake in 250 mL of 1.25 mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com