High-skin-retention glabridin nano composition as well as preparation method and application thereof

A nano-composite, the technology of glabridin, which is applied in the directions of skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problem of inability to achieve skin care effects, poor skin permeability and retention of glabridin, and reduce cosmetics. Stability and other issues, to achieve the effect of increasing skin retention, increasing skin penetration, and improving skin permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

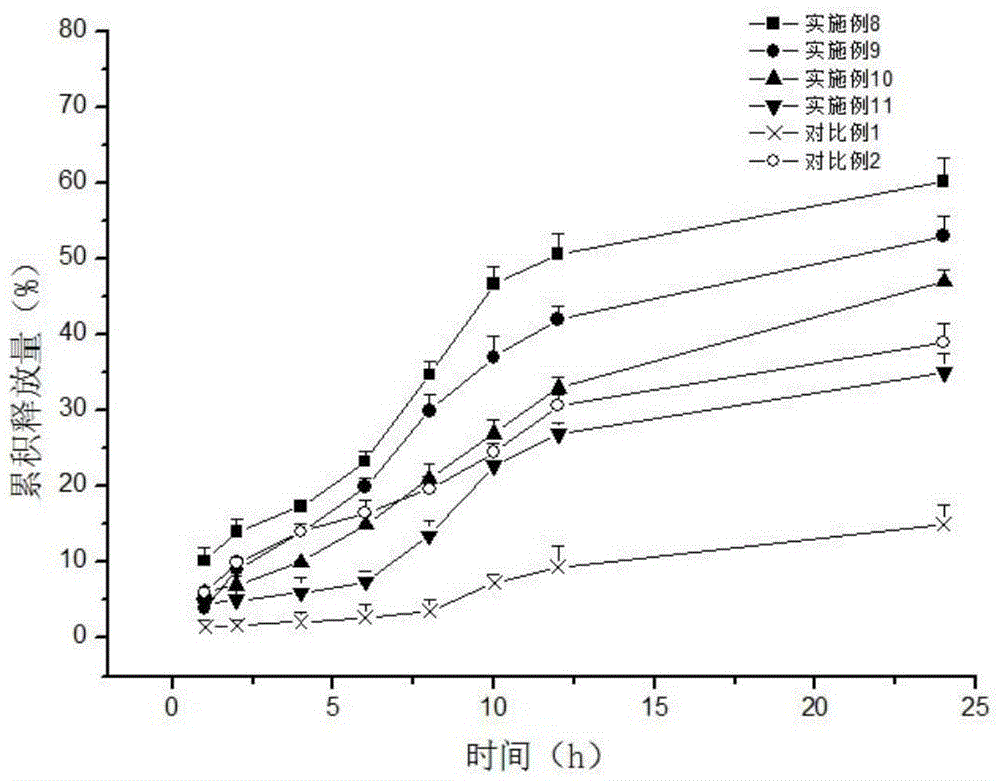

Examples

Embodiment 1

[0045] (1) Preparation of oil phase: 2.0% triglyceride behenate, 1.0% caprylic triglyceride, 0.5% octyldodecyl alcohol, melted in a water bath at 65°C; add 0.1% glabridin after melting, Mix well and set aside;

[0046] (2) Water phase: add 0.5% vitamin E polyethylene glycol succinate and 10.0% glycerin to 85.9% purified water, stir and dissolve in a water bath at 65°C, and set aside;

[0047] (3) Preparation of micron-scale dispersion: add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2), and keep stirring, and then 5000rpm high-speed shear emulsification for 10min to make a micron-scale dispersion ;

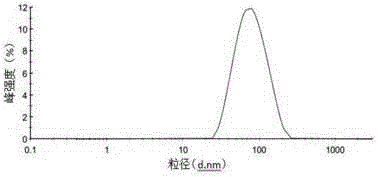

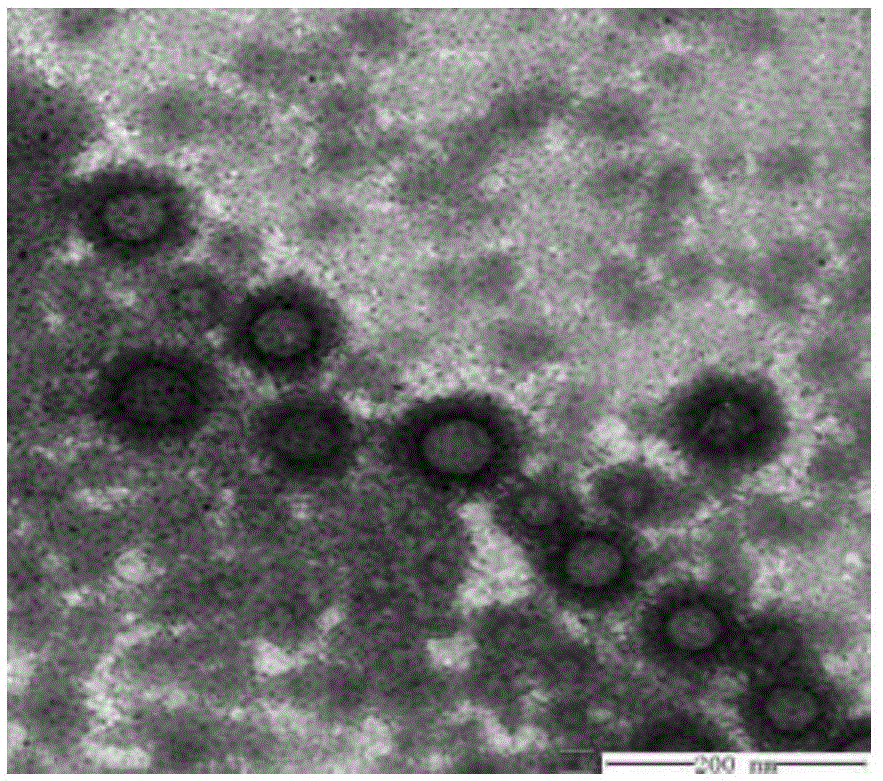

[0048] (4) Preparation of nano-composition: the micron-sized dispersion prepared in step (3) was circulated twice through high-pressure homogenization at 1200 bar to obtain a glabridin nano-composition. The particle diameter of the glabridin nano composition is 65.2nm, and the encapsulation efficiency is 81.7%.

Embodiment 2

[0050] (1) Prepare the oil phase: 4.0% soybean lecithin, 1.0% squalene, 1.0% caprylic capric glyceride, 0.5% octyl dodecanol, melt in a water bath at 70°C; add 0.5% glabridin after melting , mix well, set aside;

[0051] (2) Prepare the water phase: add 1.0% vitamin E polyethylene glycol succinate and 5.0% 1,3-butanediol to 87.0% purified water, stir and dissolve in a water bath at 70°C, and set aside;

[0052] (3) Preparation of micron-scale dispersion: add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2), and keep stirring, then 8000rpm high-speed shear emulsification for 3min to make a micron-scale dispersion ;

[0053] (4) Preparation of nano-composition: the micron-sized dispersion prepared in step (3) was circulated three times through a high-pressure micro-jet at 1200 bar to obtain a glabridin nano-composition. The particle size of the glabridin nano composition is 57.4nm, and the encapsulation efficiency is 78.9%.

Embodiment 3

[0055] (1) Preparation of oil phase: 2.0% glyceryl monostearate, 2.0% glyceryl laurate, 2.0% isopropyl myristate, 1.0% soybean oil, 1.0% octyldodecyl alcohol, make in a water bath at 90°C Melting; after melting, add 1.0% glabridin, mix evenly, and set aside;

[0056] (2) Prepare the water phase: add 1.5% vitamin E polyethylene glycol succinate, 7.0% glycerin, and 9.0% 1,2-pentanediol to 73.5% purified water, stir and dissolve in a water bath at 90°C, and set aside;

[0057] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2), and keep stirring, 6000rpm high-speed shear emulsification for 5min to make a micron-scale dispersion;

[0058] (4) Preparation of nano-composition: the micron-sized dispersion prepared in step (3) was circulated 10 times through high-pressure homogenization at 500 bar to obtain a glabridin nano-composition. The particle size of the glabridin nano composition is 51.9nm, and the enc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com