High recovery method of waste phosphoric acid film during electrode foil production

A waste phosphoric acid membrane and recovery method technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low acid recovery rate, high equipment cost, increased cost, etc., and achieve improved acid recovery rate and economic benefits Improve and realize the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

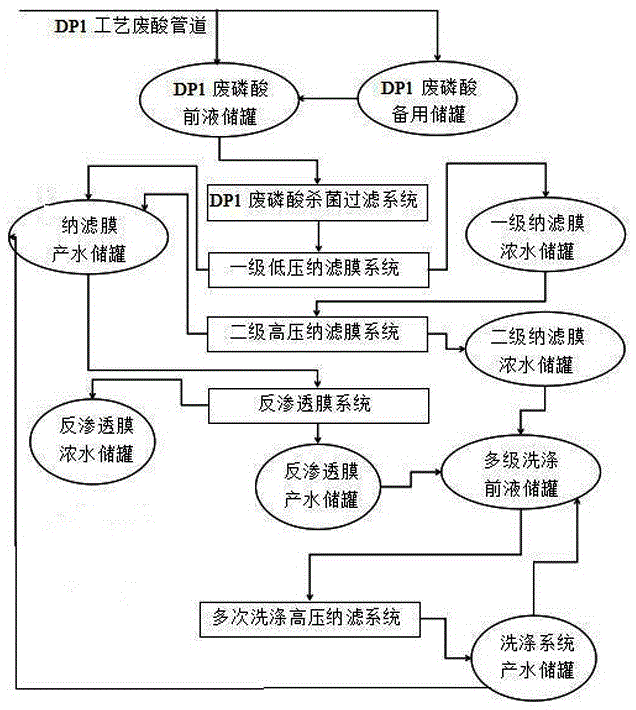

[0027] Such as figure 1Shown: the present invention includes DP1 process waste acid pipeline, DP1 waste phosphoric acid pre-liquid storage tank, DP1 waste phosphoric acid standby storage tank, DP1 waste phosphoric acid sterilization filtration system, first-level low-pressure nanofiltration membrane system, second-level high-pressure nanofiltration membrane system, Reverse osmosis membrane system, reverse osmosis membrane production water storage tank, multiple washing high-pressure nanofiltration system, nanofiltration membrane production water storage tank, reverse osmosis membrane concentrated water storage tank, washing system production water storage tank, primary nanofiltration membrane concentration Water storage tank, secondary nanofiltration membrane concentrated water storage tank, multi-stage washing liquid storage tank and washing system production water storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com