High-temperature flame-retardant environment-friendly polyolefin cable material and preparation method thereof

A polyolefin cable material, an environmentally friendly technology, applied in the direction of plastic/resin/wax insulators, rubber insulators, organic insulators, etc., can solve the problems of high hardness and low heat resistance temperature, and achieve good overall performance, good high temperature resistance and The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

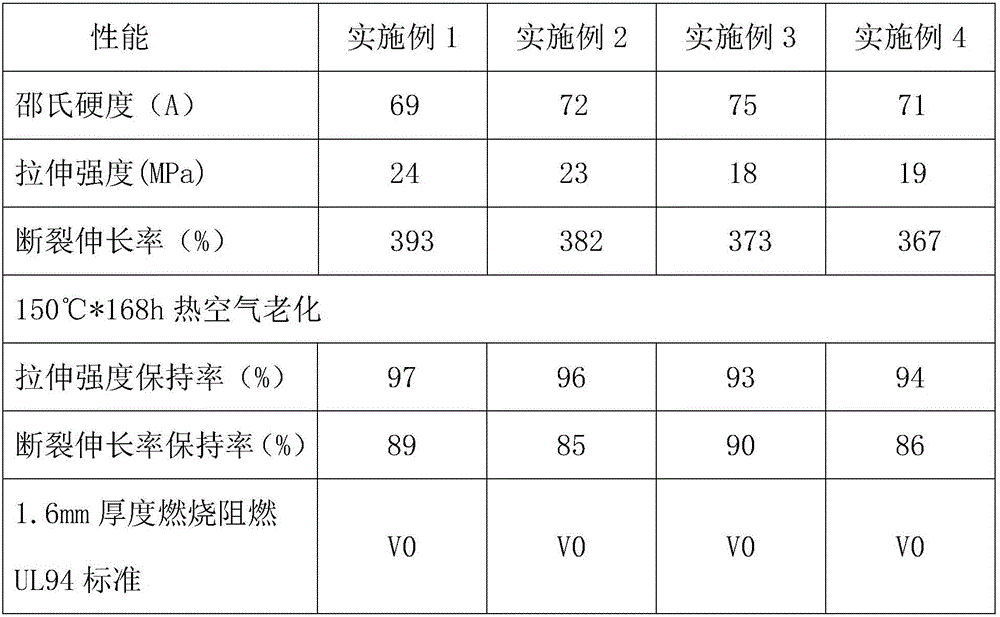

Examples

Embodiment 1

[0023] A high-temperature flame-retardant and environment-friendly polyolefin cable material, the raw materials of which include by weight: 35 parts of EPDM rubber, 25 parts of polypropylene, 5 parts of high-density polyethylene, 10 parts of polyorganosilicon oxide, and 5 parts of polyphosphate 5 parts of iron oxide, 0.5 parts of calcium stearate, 5 parts of talc, 1 part of carbon black, 20 parts of naphthenic oil, 2,5-bis(tert-butyl peroxide)-2,5-dimethyl -0.3 parts of 3-hexyne, 2 parts of diphenylmethane bismaleimide, 1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, hindered amine 3 parts of light stabilizer;

[0024] The EPDM rubber is formed by copolymerization of ethylene, propylene and ethylidene norbornene, the content of ethylene is 45wt%, the content of propylene is 40wt%, and the content of ethylidene norbornene is 15wt%; the polypropylene It is a propylene homopolymer with a melt index of 10g / 10min (230°C, 2.16kg);

[002...

Embodiment 2

[0027]A high-temperature flame-retardant and environment-friendly polyolefin cable material, the raw materials of which include by weight: 55 parts of EPDM rubber, 15 parts of polypropylene, 10 parts of high-density polyethylene, 5 parts of polyorganosilicon oxide, and 15 parts of polyphosphate 1 part of aluminum oxide, 1 part of calcium stearate, 1 part of talcum powder, 3 parts of carbon black, 5 parts of linear paraffin oil, 2,5-bis(tert-butyl peroxide)-2,5-dimethyl 1.5 parts of alkyl hexane, 0.2 parts of 1,6-hexanediol diacrylate, 3 parts of tris(2,4-di-tert-butylphenyl) phosphite, 1 part of triazine light stabilizer;

[0028] The EPDM rubber is formed by copolymerization of ethylene, propylene and ethylene norbornene, the content of ethylene is 65wt%, the content of propylene is 20wt%, and the content of ethylene norbornene is 15wt%; the polypropylene is ethylene - Propylene copolymers having a melt index of 50 g / 10 min (230 °C, 2.16 kg);

[0029] The method for preparin...

Embodiment 3

[0031] A high-temperature flame-retardant and environment-friendly polyolefin cable material, the raw materials of which include by weight: 45 parts of EPDM rubber, 20 parts of polypropylene, 7 parts of high-density polyethylene, 8 parts of polyorganosilicon oxide, and 10 parts of polyphosphate 3 parts, metal oxide 3 parts, calcium stearate 0.8 parts, talcum powder 3 parts, carbon black 2 parts, rubber oil 12 parts, dicumyl peroxide 0.9 parts, trimethylolpropane trimethacrylate 1.1 parts 2 parts, 2 parts of 2,6-di-tert-butyl-p-cresol, 2 parts of organic nickel complexes;

[0032] The EPDM rubber is formed by copolymerization of ethylene, propylene and ethylidene norbornene, the content of ethylene is 55wt%, the content of propylene is 40wt%, and the content of ethylidene norbornene is 5wt%; the polypropylene is Propylene homopolymer, its melt index is 30g / 10min (230 ℃, 2.16kg);

[0033] The method for preparing the polyorganosilicon oxide includes: heating 10 parts of glyceri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com