Grease source sodium/zinc composite liquid heat stabilizer for PVC and its preparation method and application

A compound liquid and thermal stabilizer technology, applied in the field of plastic additives, can solve the problems of poor thermal stability, dust pollution, low volatility, etc., and achieve the effect of improving thermal stability, reducing dust pollution, and promoting the use of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

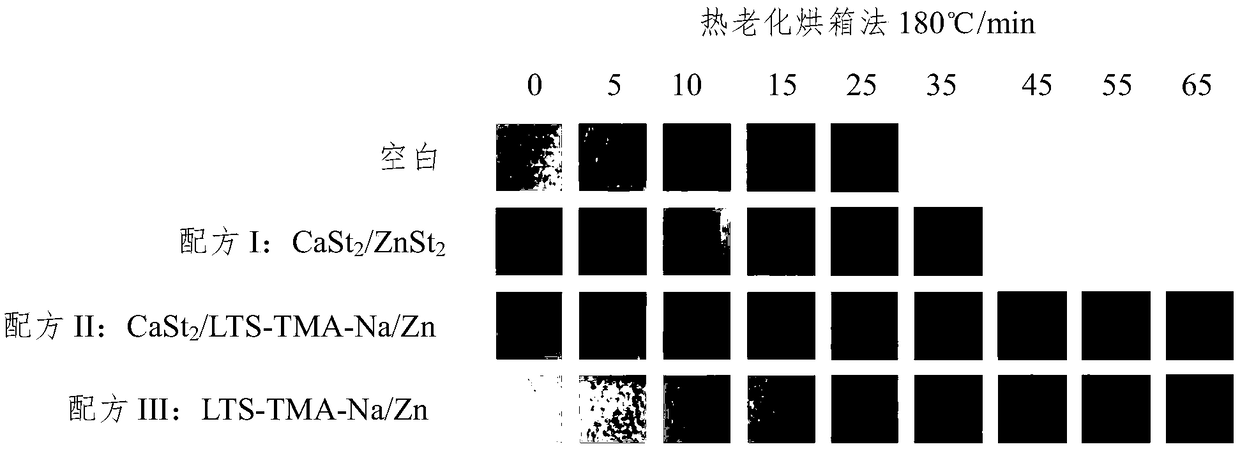

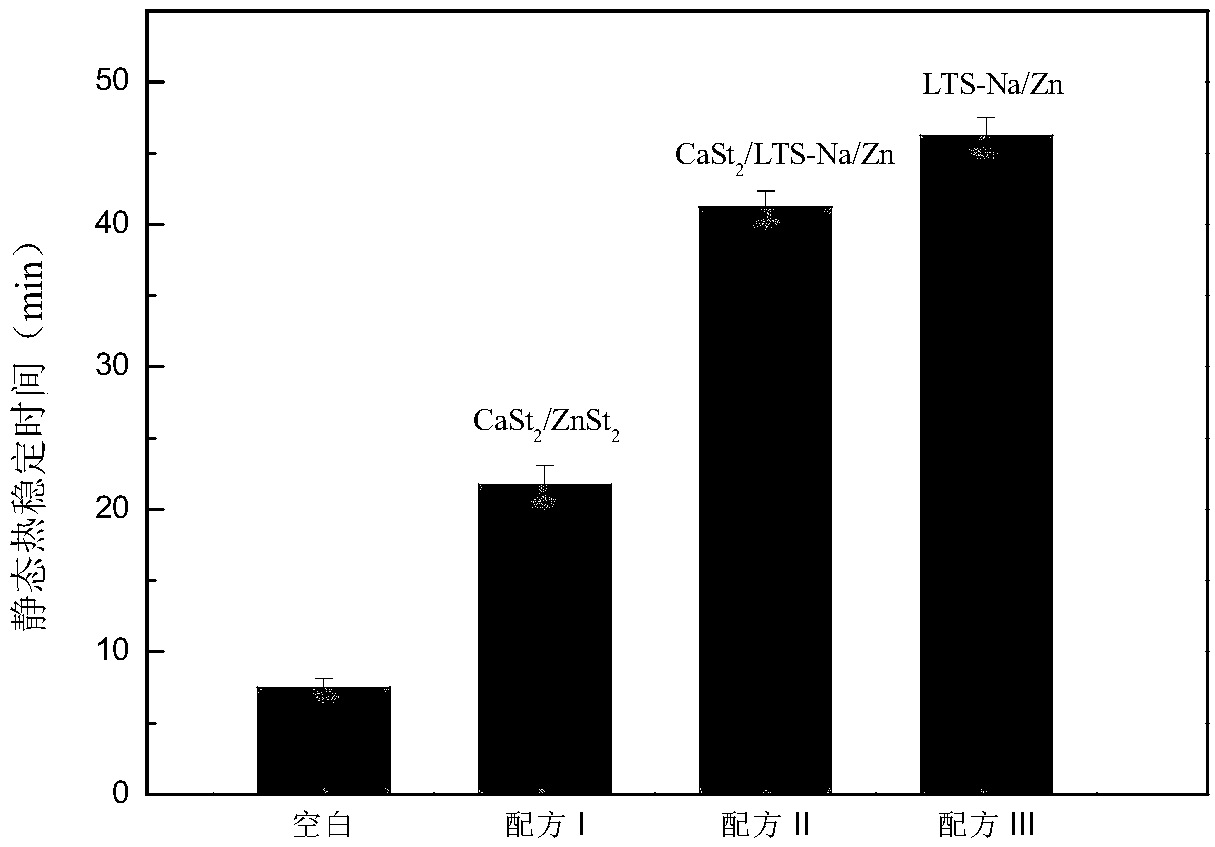

Examples

Embodiment 1

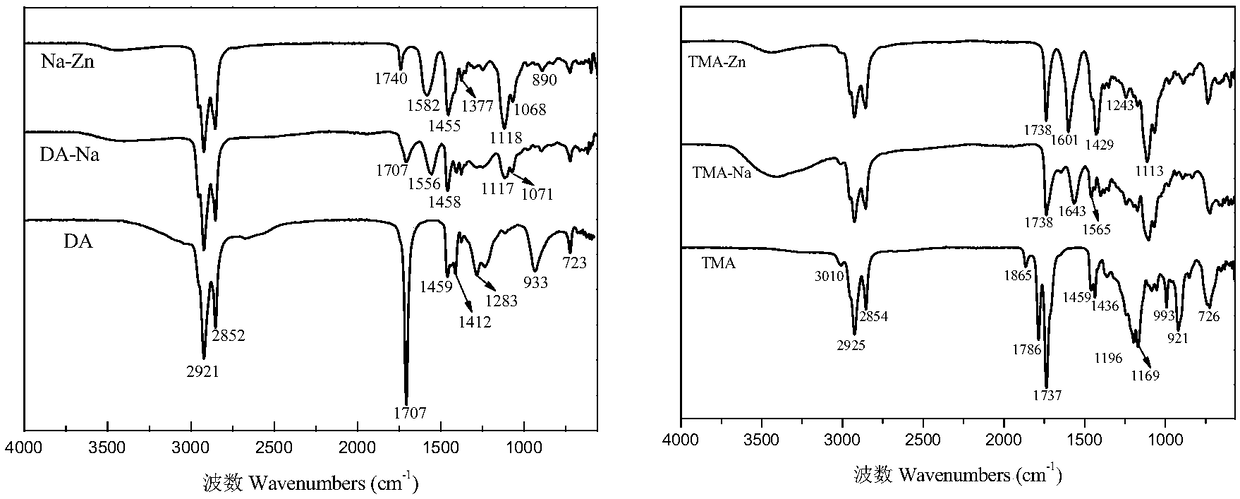

[0023] The first step, preparation of fat source liquid sodium: 1mol tungalin anhydride (TMA) (or 1mol dimer fatty acid (DA)) is added in reaction bottle, and component is 90wt.% diethylene glycol monobutyl ether and 10wt.% After mixing the organic solvent of liquid paraffin (the addition amount is 50% of TMA mass or 20% of DA mass), heat to 85°C, prepare 1.1mol NaOH into 80% (w / w) aqueous solution, add NaOH aqueous solution dropwise In the reaction bottle, after the dropwise addition is completed, after being incubated at 75° C. for 1 h, after the water in the solvent is distilled off under a vacuum of 1 to 2 mmHg, the heating is stopped, and the temperature is cooled to room temperature to obtain the oil source liquid sodium, which is sodium dimer acid ( DA-Na) and sodium traimate (TMA-Na).

[0024] The second step is to prepare the oil source liquid zinc: mix 0.95 mol zinc oxide, 1 mol TMA (or 1 mol DA), 200 mL of high boiling point petroleum ether, and 300 mL of propylene ...

Embodiment 2

[0028] The first step is to prepare the oil source liquid sodium: 1mol propylene oleic acid is added in the reaction flask, and the main components are diethylene glycol monobutyl ether and liquid paraffin organic solvent (the addition is 45% of the propylene oleic acid quality) and mixed After uniformity, heat to 65°C, prepare 1.55mol NaOH into an 80% (w / w) aqueous solution, drop NaOH aqueous solution into the reaction bottle, after the dropwise addition, keep warm at 75°C for 1 hour, and then vacuum After distilling off the water in the solvent at 100°C, stop heating and cool down to room temperature to obtain the oil source liquid sodium.

[0029] The second step is to prepare liquid zinc as a grease source: stir 1 mol of zinc oxide, 1 mol of acrylic acid and 200 mL of 1,4-dioxane evenly, and then heat it at 115°C for 1.5h, then raise the temperature to 120°C for 5h, and then heat it at 120°C for 5h. After distilling off 1,4-dioxane and water under a vacuum of 1 to 2 mmHg, ...

Embodiment 3

[0032] The first step, prepare fat source liquid sodium: 0.7mol dimer acid, 0.3mol propylene lyric acid are added in the reaction flask, and main component is the organic solvent of 80% diethylene glycol monobutyl ether and 20% liquid paraffin (adding The amount is 45% of the total mass of dimer acid and acrylic acid), and after mixing evenly, heat to 75°C, prepare 1.65mol NaOH into an 80% (w / w) aqueous solution, add NaOH aqueous solution to the reaction flask dropwise, After the addition is complete, keep the temperature at 80°C for 1 hour, distill off the water in the solvent under a vacuum of 1-2 mmHg, stop heating, cool down to room temperature, and obtain the oil source liquid sodium.

[0033] The second step is to prepare the oil source liquid zinc: stir 0.8mol zinc oxide, 0.7mol dimer acid, 0.3mol acrylic acid and 300mL propylene glycol methyl ether, and keep it at 115°C for 1.5h, then heat it up to 135°C 4h, after distilling off propylene glycol methyl ether and water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com