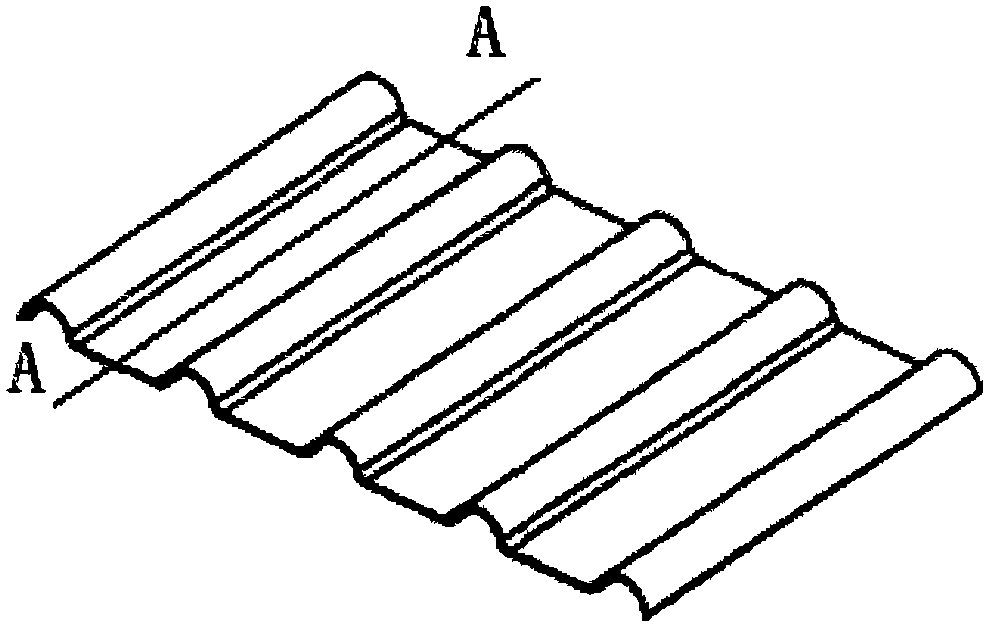

Composite corrosion-resistant magnesium oxychloride tile

A magnesium oxychloride, corrosion-resistant technology, used in roofing, roofing, buildings and other directions using tiles/slate tiles, can solve the problems of unsaturated resin tiles that are not fireproof, human body damage, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1. with lightly burned magnesia powder (magnesia content 85%, active magnesia 55%) 100kg, Baume degree is the magnesium chloride solution 68kg of 25 degrees, 180-200 order diabase powder 30kg, fly ash 6kg, Wood chips 4kg, compound modifier (orthophosphoric acid + acrylic acid emulsion + FDN water reducer) 2.0kg.

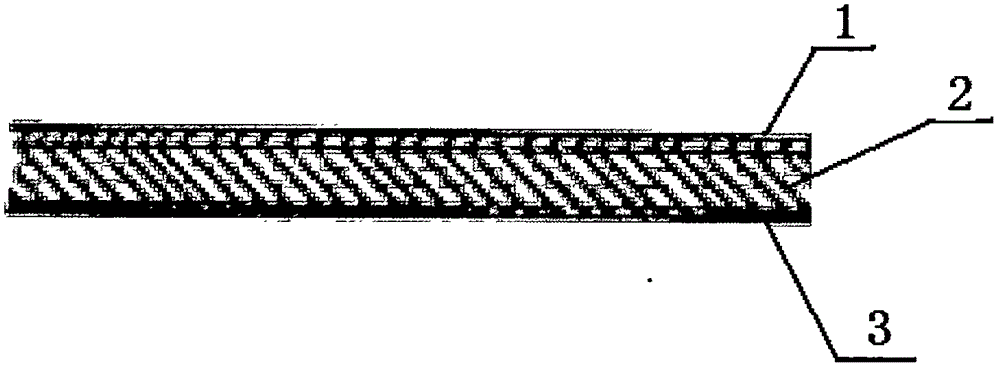

[0018] Process: Put the above materials into the mortar mixer and stir for 10-15 minutes to form a slurry, and shape it on the mechanical molding machine in the following order: BOPP tape→material general→fiber mesh cloth→material general→fiber mesh cloth→material Put → non-woven fabric → forming mold → static hardening → demoulding → spraying silicone acrylic paint (primer, middle layer 2 texture paint, finish paint) → drying → inspection → storage.

example 2

[0019] Example 2. Lightly burned magnesia powder (magnesia content 85%, activated magnesia 60%) 100kg, Baume degree is 71kg of magnesium chloride solution 71kg of 28 degrees, 180-200 order diabase powder 40kg, fly ash 8kg, sawdust 5kg, composite modifier (orthophosphoric acid + acrylic acid emulsion + FDN superplasticizer) 2.3kg. .

[0020] Technological process is identical with example 1.

example 3

[0021] Example 3. lightly burned magnesia powder (magnesia content 85%, activated magnesia 65%) 100kg, Baume degree is 75kg of magnesium chloride solution of 30 degrees, 180-200 order diabase powder 50kg, fly ash 10kg, sawdust 6kg, composite modifier (orthophosphoric acid + acrylic acid emulsion + FDN superplasticizer) 2.5kg.

[0022] Technological process is identical with example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com