Biquaternary ammonium salt and method for synthesizing MFI type molecular sieve and molecular sieve membrane

A double quaternary ammonium salt and molecular sieve technology, which is applied in the direction of molecular sieves and base exchange compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of expensive raw materials, slow growth, and complex synthesis of templates Growth rate, effect of increased size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of hexapropylhexamethylene diammonium bromide (dimer-TPABr) template, the preparation method is as follows: get 1,6-dibromohexane as 18g, tri-n-propylamine 35mL, be dissolved in 30mL dehydrated alcohol or acetonitrile , and placed in a round-bottomed flask for reflux and stirring, the reflux temperature is 75-85°C; the reaction time is 40-50h. After cooling, it was dissolved in ethyl acetate for recrystallization, and the white solid powder obtained by recrystallization was placed in an oven at 60°C and dried to obtain hexapropylhexamethylene diammonium bromide (dimer-TPABr) template agent. Store in a desiccator.

[0042] The reaction equation is:

[0043]

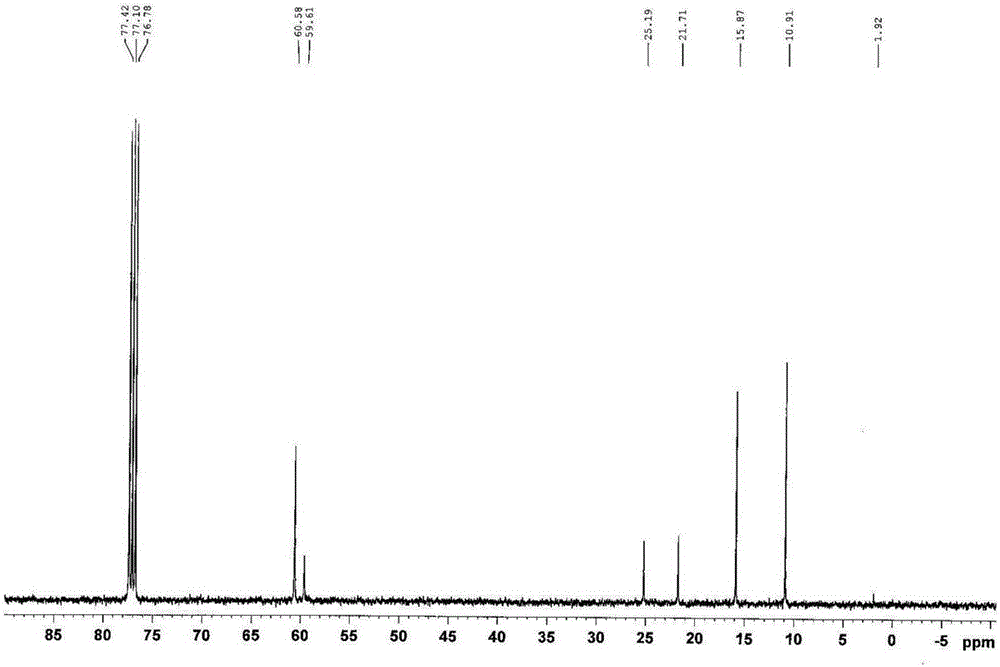

[0044] The chemical structure of the product is characterized by a BRUKER AV400 nuclear magnetic resonance instrument, TMS is used as an internal standard, and the unit is ppm; its 13CNMR spectrum is as follows: figure 1 As shown, the chemical shift δ corresponding to each carbon atom in the fig...

Embodiment 2

[0046] The preparation of hexapropylhexamethylene diiodide ammonium iodide (dimer-TPAI) template is as follows: get 20g of 1,6-diiodohexane, 40mL of tri-n-propylamine, dissolve in 30mL of ethyl acetate, place in a circular Reflux and stir in the bottom flask, the reaction reflux temperature is 85-100°C, the reaction time is 30-40h, after cooling, it is dissolved in ethyl acetate for recrystallization, and the white solid powder obtained by recrystallization is dried in an oven at 60°C , to obtain hexapropylhexamethylene diiodide ammonium (dimer-TPAI) template agent, stored in a desiccator. The reaction equation is as follows:

[0047]

[0048] The chemical structure of the product is characterized by BRUKER AV400 nuclear magnetic resonance instrument, TMS is used as the internal standard, and the unit is ppm; the chemical shift δ corresponding to each carbon atom in the 13CNMR spectrum is: 11.0(3), 16.0(3), 22.2(1), 26.4(1 ), 59.3(1), 61.1(3), which are basically consistent ...

Embodiment 3

[0050] Synthesis of MFI-type molecular sieves using diquaternary ammonium salts as templates:

[0051] (1) According to ethyl orthosilicate: KOH: dimer-TPABr: H 2 O=40:25:7.5:9500 molar ratio, mix KOH, dimer-TPABr and deionized water to form a solution, and then add tetraethyl orthosilicate dropwise to the solution under vigorous stirring, at 25°C Aged for 5 hours to obtain MFI type molecular sieve synthetic gel.

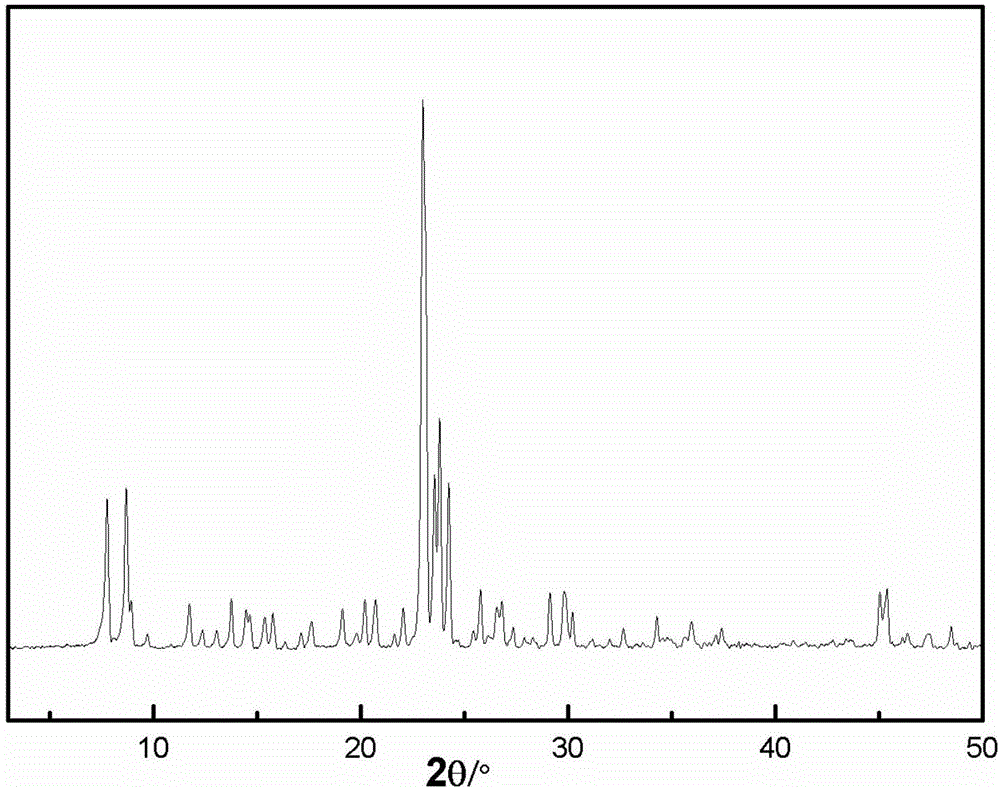

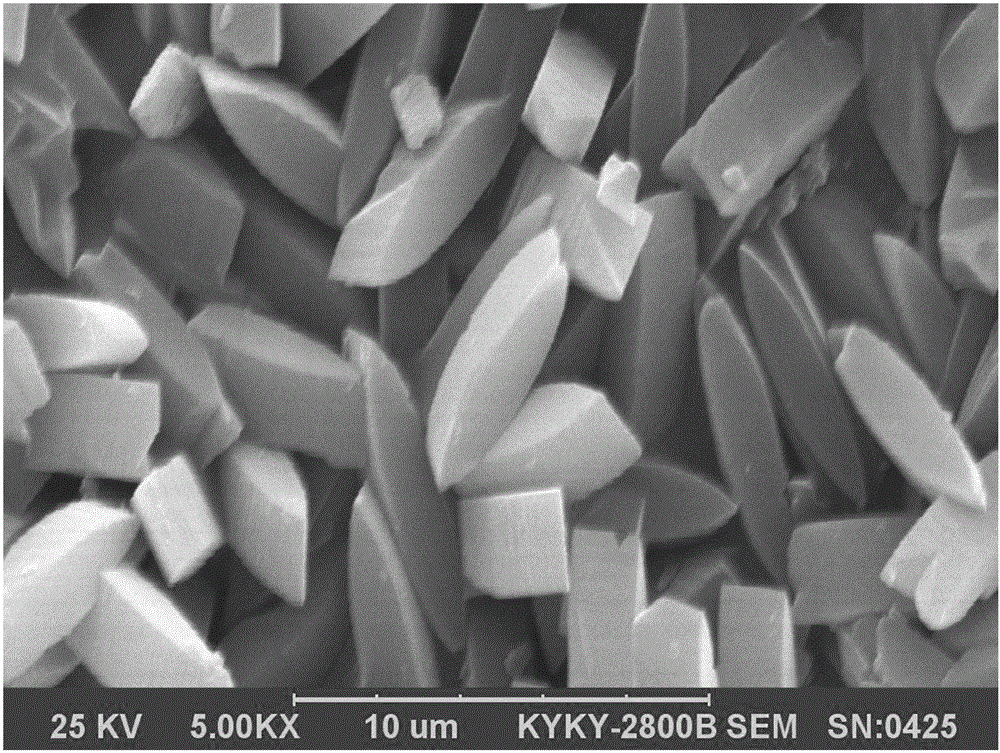

[0052] (2) Transfer the obtained synthetic gel of molecular sieve into a closed stainless steel reaction kettle with polytetrafluoroethylene lining, hydrothermally crystallize at 175°C for 24 hours, take out the sample and cool it, wash with distilled water, dry, and recover the molecular sieve sample . Molecular sieve crystals were characterized by a Japanese Rigaku D / MAX-2200PC X-ray powder diffractometer and a KYKY-2800 scanning electron microscope. The X-ray diffraction spectrum and scanning electron microscope (SEM) photos are shown in figure 2 and image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com