Plate-type low-temperature catalyst adopting crosslinked nanochain self-assembly porous spherical titanium dioxide as carrier, and preparation method and application thereof

A titanium dioxide, self-assembly technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as poor selectivity, sulfur resistance, and poor activity. Achieve the effects of simple preparation process, low cost, and easy-to-obtain preparation raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

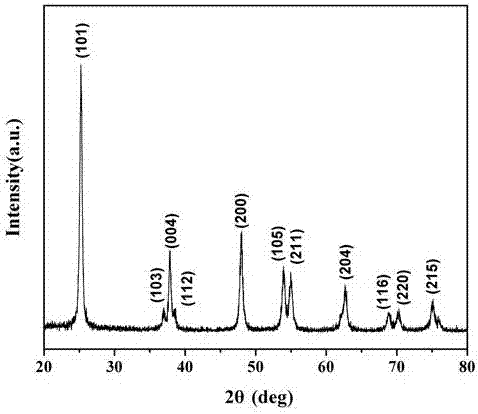

[0035] Dissolve 0.03 mol of ammonium hexafluorotitanate in 140 mL of deionized water, place the solution in a three-necked flask with stirring and heating in an oil bath, place 1 mol of ammonia water in a separatory funnel, and control the dropping rate to 0.5-1 drop / second, At the same time, the mixed solution was rapidly heated to 90 °C and kept at this temperature for 3.5 hours. After the ammonia water was dripped, the reaction was continued for 2 hours. After the reaction was completed, it was naturally cooled to room temperature to obtain product A; the product A was centrifuged, washed, and dried ; The product A was placed in a muffle furnace, heated to 550°C at a rate of 3°C / min, and calcined in an air atmosphere for 2 hours to obtain the final product B.

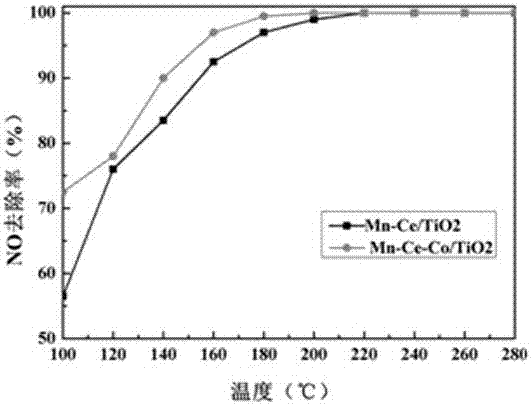

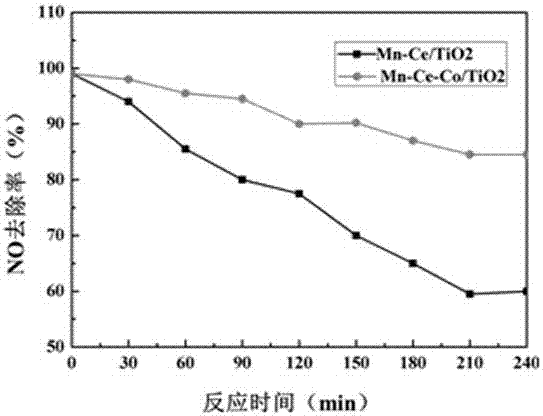

[0036]Mix 1.25 mol of product B prepared above with 6.5 g of glass fiber in a kneader and stir evenly, and add 5 g of ammonia water. Manganese acetate 0.4mol, cerium nitrate 0.08mol and cobalt nitrate 0.1mol are prep...

Embodiment 2

[0039] Dissolve 0.01 mol of titanium alkoxide in 80 mL of deionized water, place the solution in a three-necked flask with stirring and heating in an oil bath, place 1 mol of urea aqueous solution in a separatory funnel, and control the dropping rate of 0.5-1 drop / second, while Rapidly raise the temperature of the mixed solution to 60°C and keep it at this temperature for 1 hour, continue to react for 2 hours after the urea aqueous solution is dripped, and naturally cool to room temperature after the reaction to obtain product A; centrifuge, wash and dry the product A ; Place the product A in a muffle furnace, heat it to 450°C at a heating rate of 3.5°C / min, and calcinate it in an air atmosphere for 5 hours to obtain the final product B.

[0040] Mix 0.5 mol of product B prepared above with 3 g of glass fiber in a kneader and stir evenly, and add 2 g of ammonia water. 0.1mol of manganese acetate, 0.01mol of cerium nitrate and 0.05mol of cobalt sulfate are prepared into a 30mL ...

Embodiment 3

[0043] Dissolve 0.05 mol of ammonium hexafluorotitanate and titanium alkoxide in 198 mL of deionized water, place the solution in a three-necked flask with stirring and heating in an oil bath, place 1 mol of sodium hydroxide aqueous solution in a separatory funnel, and control the dropping rate 0.5-1 drop / second, at the same time, the mixed solution is rapidly heated to 75°C and kept at this temperature for 6 hours, and the reaction is continued for 2 hours after the aqueous sodium hydroxide solution is dripped, and naturally cooled to room temperature after the reaction, to obtain product A; The product A was centrifuged, washed, and dried; the product A was placed in a muffle furnace, heated to 650°C at a heating rate of 10°C / min, and calcined in an air atmosphere for 3 hours to obtain the final product B.

[0044] Mix 2 mol of product B prepared above with 10 g of glass fiber in a kneader and stir evenly, and add 8 g of ammonia water. Manganese nitrate and manganese acetate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com