TiO2 grading structure with visible light response and preparation method thereof

A hierarchical structure, visible light technology, applied in chemical instruments and methods, chemical/physical processes, titanium oxide/hydroxide, etc., can solve the problems of low photoelectric energy conversion efficiency, low visible light response, etc. The effect of large surface area and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] TiO with visible light response of the present invention 2 The preparation method of hierarchical structure, concrete steps are as follows:

[0032] (a) dissolving acetic acid and fluoride salts with a mass ratio of 12:0.22 to 12:0.26 in water to form a clear aqueous solution as reaction raw materials; the mass percentage concentration of the acetic acid is 57%-59%; the mass percentage of the fluoride salts The concentration is 1.0%-1.2%; the fluoride salt is ammonium fluoride, sodium fluoride, or potassium fluoride;

[0033] (b) adding tetra-n-butyl titanate with a mass percentage concentration of 1.6%-2.0% into the clear aqueous solution dropwise, and continuously stirring evenly;

[0034] (c) Transfer the aqueous solution added dropwise with tetra-n-butyl titanate into a hydrothermal reaction kettle, put it into an oven, raise the temperature to 140-180°C, and keep it warm for a period of time, which is more than 8 hours;

[0035] (d) Take out the precipitated subs...

Embodiment 1

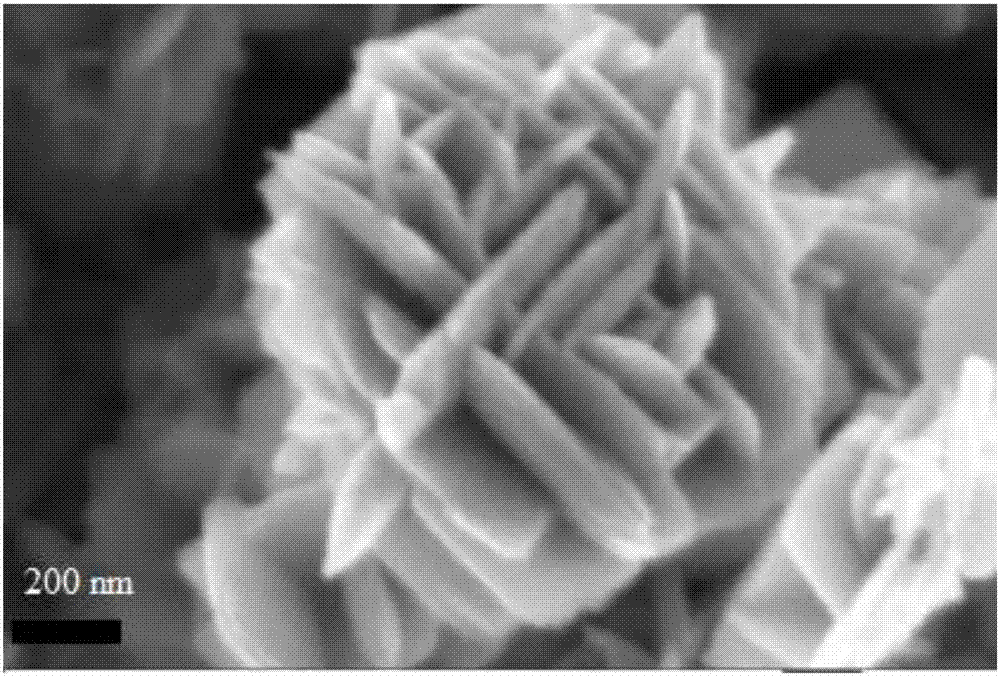

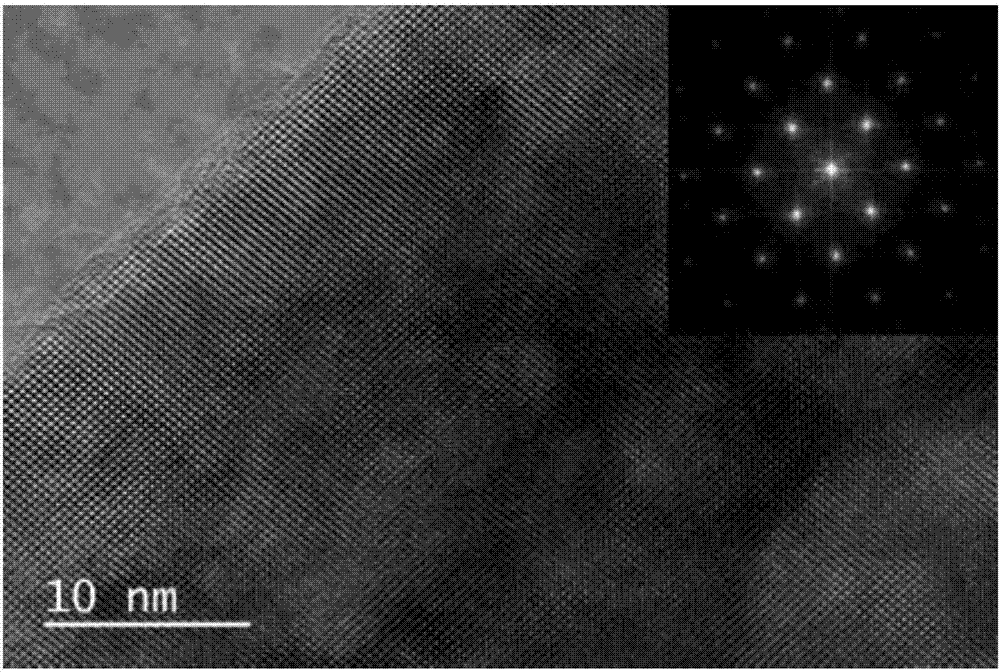

[0038] Dissolve 0.24g of ammonium fluoride in 8mL of water, then add 12mL of acetic acid, stir for 5min to make it uniform, then slowly drop in 0.5mL of tetra-n-butyl titanate and keep stirring for 5min, then pour the obtained solution into polytetrafluoroethylene Put it into a 35mL reaction kettle composed of a vinyl liner and a stainless steel shell, and put it in an oven at 160°C for 9 hours; after natural cooling, take out the precipitate, centrifuge, wash, and dry; finally, put the obtained white powder in Sintered at 400 °C for 1.5 h in a muffle furnace to obtain yellow TiO with visible light response 2 Nanomaterials; the macroscopic and microscopic morphological characteristics of the material are as follows: figure 1 shown; the nanostructure is composed of a series of single crystal flakes in the shape of a "rose flower", figure 2 , image 3 As shown; there is a small amount of F element in the lattice, and the F element is due to the diffusion of F in the impurity ...

Embodiment 2

[0040]Dissolve 0.71g of ammonium fluoride in 24mL of water, then add 36mL of acetic acid, stir for 5min to make it uniform, then slowly drop in 1.5mL of tetra-n-butyl titanate and keep stirring for 10min, then pour the obtained solution into polytetrafluoroethylene Put it into a 100mL reaction kettle composed of a vinyl liner and a stainless steel shell, and put it in an oven at 140°C for 12 hours; after natural cooling, take out the precipitate, centrifuge, wash, and dry; then place the white powder obtained In a muffle furnace, sintered at 450 °C for 2 h, the yellow TiO with visible light response was obtained 2 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com