Preparation method for graphene-molybdenum disulfide-polyaniline ternary composite electrode material

A molybdenum disulfide, ternary composite technology, applied in the field of material science, can solve the problems of cycle stability and related electrochemical performance reduction, harsh process conditions, complex production process, etc., to achieve good electrochemical performance, excellent cycle performance, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

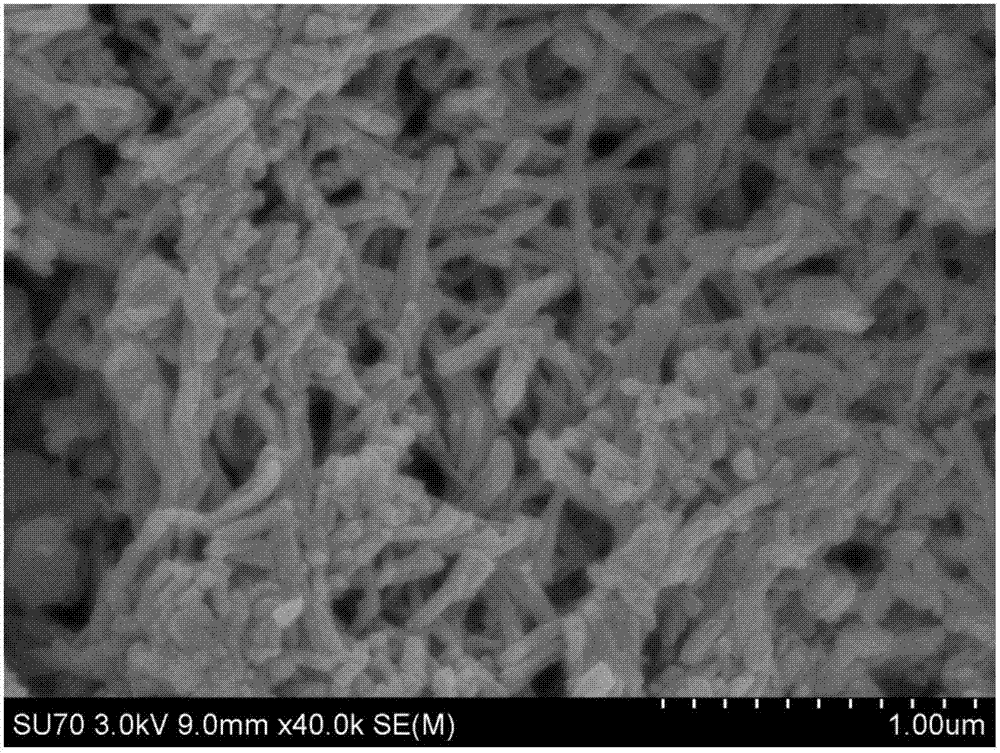

[0030] (1) Take 12mg, 16mg, 20mg, 24mg, 40mg of graphene respectively into 40ml deionized water and ultrasonically disperse for 30min, then 0.4318g MoO 3 Add 0.728g of potassium thiocyanide to the above solution, magnetically stir for 20 minutes to make it uniformly dispersed, transfer the solution into a 50ml stainless steel reactor with a polytetrafluoroethylene liner, and react at 210°C for 24 hours.

[0031] (2) After the reaction, the black precipitated product was obtained by centrifugal separation, which were marked as M1, M2, M3, M4, M5, and the precipitated product was washed 3 times with ethanol and deionized water, and then moved into an oven at 60°C to dry to obtain the matrix powder.

[0032] (3) Take 0.04g of the above-mentioned dried M1, M2, M3, M4, and M5 matrix powder, and disperse them evenly in 100ml of hydrochloric acid solution with a concentration of 1mol / L, add 1ml of aniline monomer and stir evenly for 15min, then add Add 100ml to the mixed solution containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com