An attapulgite-graphite-like-phased carbon nitride-poly(vinylidene fluoride) nanometer composite ultrafiltration membrane, a preparing method thereof and applications of the membrane

A technology of graphite phase carbon nitride and polyvinylidene fluoride membrane, which is applied in chemical instruments and methods, ultrafiltration, special compound water treatment, etc., can solve the problems of section, bottom surface structure and performance without improvement, and improve anti-pollution And self-cleaning performance, the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the ultrafiltration membrane can be obtained by common phase inversion methods, such as immersion precipitation phase inversion and thermally induced phase inversion coupling process, firstly, attapulgite-graphite-like carbon nitride composite material, PVDF, organic solvent After mixing and dispersing, a casting liquid is obtained, and after the casting liquid undergoes phase transformation in the solidification liquid, an ultrafiltration membrane with a microporous structure can be obtained.

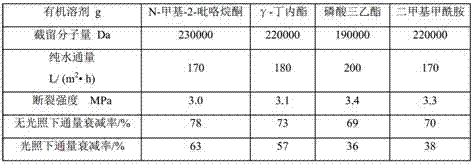

[0047] Here, the organic solvent refers to a substance that dissolves polyvinylidene fluoride resin, and examples thereof include N-methyl-2-pyrrolidone, tetrahydrofuran, dimethyl sulfoxide, tetramethyl urea; Amides such as methylformamide; esters or lactones such as trimethyl phosphate, triethyl phosphate, γ-butyrolactone; and their mixed solvents.

[0048] In the above-mentioned method, the non-solvent of the coagulation liquid includes, for example, ...

Embodiment 1

[0055] Example 1 Preparation of attapulgite-graphite-like carbon nitride composite material

[0056] Weigh 3.02g of silane coupling agent-modified attapulgite and disperse it in 1000mL of deionized water, and ultrasonically disperse; then add 6.01g of melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to a quartz boat , place the quartz boat in a tube furnace, and program the temperature in the tube furnace under an air atmosphere. The heating program is as follows: the room temperature is increased to 500 °C for 0.5 h, kept at 500 °C for 2 h, and then heated to 520 °C for 2 min. After 2 hours, the temperature was naturally lowered, and the material was fully ground to powder to obtain attapulgite-graphite-like carbon nitride composite material (for the preparation method, refer to patent document CN106179447A).

Embodiment 2

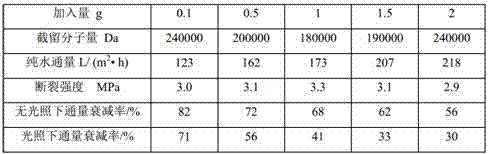

[0057] Example 2 Preparation of attapulgite-graphite-like carbon nitride composite material doped ultrafiltration membrane

[0058] 1 gram of attapulgite-graphite-like carbon nitride composite material was added to 80 grams of triethyl phosphate, after vigorous mechanical stirring and ultrasonic treatment, 20 grams of polyvinylidene fluoride powder was added and stirred at 80 °C Dissolve for 24 hours, then add 5 grams of polyethylene glycol and stir for 12 hours to obtain a casting solution, which is then left to stand for deaeration at 80°C for 24 hours. The coupling process of immersion precipitation phase inversion and thermally induced phase inversion is adopted. The conditions are: air drying process is 0 cm; the flow rate of the casting liquid is 2 mL / min; the core liquid is an aqueous suspension of attapulgite-graphite-like carbon nitride composite material, and the mass percentage of attapulgite-graphite-like carbon nitride composite material in the inner core liquid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com